This study aimed to evaluate the effects of different finishing and polishing techniques, including a novel polishing method (silicon carbide brush), on the surface roughness and morphology of nanofilled (Filtek Z350XT) and microhybrid (Filtek Z250) composite resins.

MethodsThirty-five specimens of each resin were fabricated and assigned randomly to receive the following finishing/polishing treatments (n = 5 per group): none (control), Sof-Lex Pop-On discs (POP), Praxis discs (PRA), POP + felt discs with diamond paste, POP + silicon carbide brush, PRA + felt discs with diamond paste, and PRA + silicon carbide brush. Average roughness (Ra) in μm was evaluated using a 3D profilometer. Scanning electron microscopic images were also obtained and descriptively analyzed. Two-way analysis of variance and Tukey's test (p < 0.05) were used to evaluate the effects of resin type, finishing/polishing system, and interactions between these two variables on Ra values.

ResultsFor the microhybrid resin, greater surface smoothness was obtained using POP or PRA + silicon carbide brush. For the nanofilled resin, the smoothest surface was obtained with POP + felt discs with diamond paste or silicon carbide brush.

ConclusionThe surface roughness of a composite resin depends on its composition and finishing and polishing technique used.

Este trabalho objetivou avaliar os efeitos de diferentes técnicas de acabamento e polimento, incluindo uma nova técnica de polimento (escova de carbeto de silício), na rugosidade superficial e micromorfologia de resinas compostas nanoparticulada (Filtek Z350XT), e microhíbrida (Filtek Z250).

MétodosTrinta e cinco amostras de cada resina composta foram confeccionadas e, aleatoriamente, distribuídas entre os seguintes métodos de acabamento/polimento (n = 5 por grupo): nenhum (controle), discos Sof-Lex Pop-On (POP), Praxis TDV (PRA), POP + discos de feltro com pasta diamantada, POP + escova de carbeto de silício, PRA + discos de feltro com pasta diamantada e PRA + escova de carbeto de silício. A média de rugosidade (Ra), em micrômetro, foi averiguada utilizando-se um perfilômetro 3D. Imagens foram também obtidas por meio de microscopia eletrônica de varredura (MEV) e analisadas descritivamente. Os testes de análise de variância (ANOVA) – dois critérios, e de Tukey (p < 0,05) foram empregados para avaliar os efeitos do tipo de resina, do método de acabamento/polimento, bem como a interação entre ambos.

ResultadosPara a resina composta microhíbrida, a superfície mais lisa foi obtida utilizando-se POP/PRA associado à escova de carbeto de silício. Para a resina composta nanoparticulada, a superfície mais lisa foi gerada após uso do POP associado ao disco de feltro com pasta diamantada ou à escova de carbeto de silício.

ConclusãoA rugosidade superficial de uma resina composta depende de sua composição e do método de acabamento/polimento utilizado.

With the application of nanotechnology to dental composites, nanocomposites have been proposed as restorative materials.1 Nanofilled dental composites were introduced in the market with the goal of combining strength and smoothness in a single product that offers reduced polymerization shrinkage and improved mechanical and esthetic characteristics.2

However, the presence of irregularities on restoration surfaces can influence esthetics, allows for biofilm retention and discoloration, and contributes to secondary caries.3 A high surface roughness can compromise the physical properties of composites and contributes to the wear of restorations.4–6 In this context, the use of finishing and polishing techniques for composite resins is necessary. Highly polished, smooth restorations have demonstrated several advantages, including esthetic properties and restoration longevity.7

Various finishing and polishing systems have been introduced in the market. They must be tested in combination with different composite resin types, as differences in composition may affect the final result of surface smoothness. With the evolution of composite resins and finishing and polishing materials, more studies are necessary to determine the best indications of their use to achieve restoration longevity. The effectiveness of the silicon carbide brush system for final polishing in producing smooth restoration surfaces should be evaluated. Thus, this in vitro study was conducted to evaluate and compare the surface roughness of two esthetic restorative materials subjected to different finishing (aluminum-oxide finishing discs) and polishing techniques (a classical instrument – felt discs – or a novel polishing instrument – carbide brush system). The hypothesis tested is that finishing techniques associated to the new polishing instrument carbide brush system would perform better for both composites.

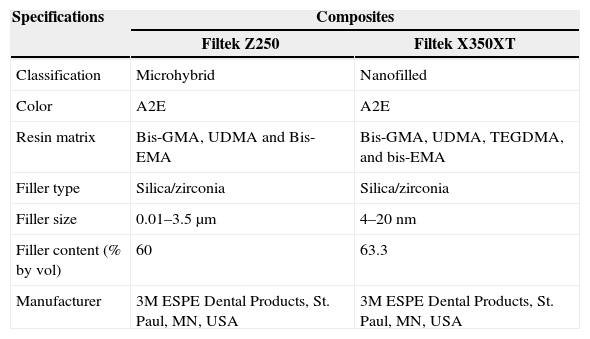

Materials and methodsTwo composite resins were used in this study, one was nanofilled (Filtek Z350XT; 3M ESPE, St. Paul, MN, USA) and the other was a microhybrid resin (Filtek Z250; 3M ESPE). The chemical components of these composites are listed in Table 1. A single operator fabricated 35 circular specimens (8-mm diameter, 2-mm height) per composite. A Teflon custom mold was placed on a glass plate and filled with composite. The composite surface was then covered with a polyester strip and photoactivated for 20s with a Coltolux light-emitting diode (1264mW/cm2 irradiance; Coltène/Whaledent, Altstatten, Switzerland). The specimens were removed from the mold and stored in plastic containers containing distilled water at 37°C for 24h before finishing/polishing procedures.

Materials used in this study.

| Specifications | Composites | |

|---|---|---|

| Filtek Z250 | Filtek X350XT | |

| Classification | Microhybrid | Nanofilled |

| Color | A2E | A2E |

| Resin matrix | Bis-GMA, UDMA and Bis-EMA | Bis-GMA, UDMA, TEGDMA, and bis-EMA |

| Filler type | Silica/zirconia | Silica/zirconia |

| Filler size | 0.01–3.5μm | 4–20nm |

| Filler content (% by vol) | 60 | 63.3 |

| Manufacturer | 3M ESPE Dental Products, St. Paul, MN, USA | 3M ESPE Dental Products, St. Paul, MN, USA |

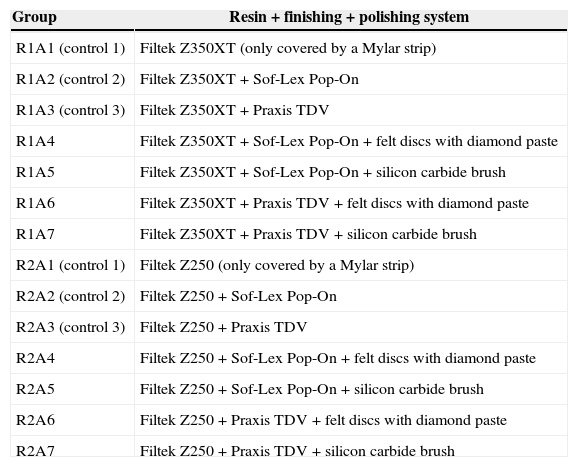

Two aluminum-oxide finishing discs (Sof-Lex Pop-On, 3M ESPE; and Praxis TDV, TDV Dental Ltda., Pomerode, Brazil) and two polishing materials (felt discs – TDV Dental Ltda., and Diamond Gloss™ polishing paste – KG Sorensen, Sao Paulo, Brazil; and the silicon carbide Astrobrush™ – Ivoclar Vivadent, Amherst, NY, USA) were used. The specimens were divided into groups according to resin type and finishing and polishing systems (n=5 per group; Table 2).

Test groups created according to resin type and finishing and polishing systems.

| Group | Resin+finishing+polishing system |

|---|---|

| R1A1 (control 1) | Filtek Z350XT (only covered by a Mylar strip) |

| R1A2 (control 2) | Filtek Z350XT+Sof-Lex Pop-On |

| R1A3 (control 3) | Filtek Z350XT+Praxis TDV |

| R1A4 | Filtek Z350XT+Sof-Lex Pop-On+felt discs with diamond paste |

| R1A5 | Filtek Z350XT+Sof-Lex Pop-On+silicon carbide brush |

| R1A6 | Filtek Z350XT+Praxis TDV+felt discs with diamond paste |

| R1A7 | Filtek Z350XT+Praxis TDV+silicon carbide brush |

| R2A1 (control 1) | Filtek Z250 (only covered by a Mylar strip) |

| R2A2 (control 2) | Filtek Z250+Sof-Lex Pop-On |

| R2A3 (control 3) | Filtek Z250+Praxis TDV |

| R2A4 | Filtek Z250+Sof-Lex Pop-On+felt discs with diamond paste |

| R2A5 | Filtek Z250+Sof-Lex Pop-On+silicon carbide brush |

| R2A6 | Filtek Z250+Praxis TDV+felt discs with diamond paste |

| R2A7 | Filtek Z250+Praxis TDV+silicon carbide brush |

R=resin, A=finishing and polishing systems.

Specimens in groups R1A2, R1A4, R1A5, R2A2, R2A4, and R2A5 received surface finishing treatment with Sof-Lex Pop-On discs, consisting of abrasion with intermittent movements in one direction at low speed for 30s. The specimens were immersed in an ultrasonic cleaner (Unique, Sao Paulo, Brazil; 25kHz power, 120W frequency) for 3min between the uses of progressively smoother discs to remove particles left by the previous disc. The same procedure was performed using Praxis TDV discs on specimens in groups R1A3, R1A6, R1A7, R2A3, R2A6, and R2A7.

Specimens in groups R1A4, R1A6, R2A4, and R2A6 were polished with felt discs and a small amount of Diamond Gloss™ polishing paste for 30s at low speed using circular motions. Discs were discarded after each use. Those in groups R1A5, R1A7, R2A5, and R2A7 received final polishing with the silicon carbide Astrobrush™ for 30s using circular motions at low speed. The same brush was used for all procedures.

After finishing and polishing, the surface roughness of specimens was evaluated using a 3D profilometer (Taylor Hobson Brazil, Ltda., São Paulo, SP, Brazil). Average surface roughness (Ra) in micrometer was defined as the distance between peaks and valleys in relation to the midline (parallel line guiding the overall direction of the rough profile) along the measurement path. Roughness readings were taken running on the sample diameter at three points, and average roughness values were calculated for each sample.

To examine changes produced on restoration surfaces by finishing and polishing, one randomly selected specimen per group was metallized with gold and observed by scanning electron microscopy (JEOL 5600 LV JLM, Tokyo, Japan). Photomicrographs of 50μ magnification for each specimen were obtained.

Roughness data were analyzed using the Assistat program (version 7.6 beta 2013, Campina Grande, PB, Brazil). The assumptions of homogeneity of variances and normal distribution of errors were checked for all the variables tested using the Bartlett and Kolmogorov–Smirnov tests, respectively. Since the assumptions were satisfied, two-way ANOVA and Tukey's post hoc t-test were used. The significance level was set at 5%.

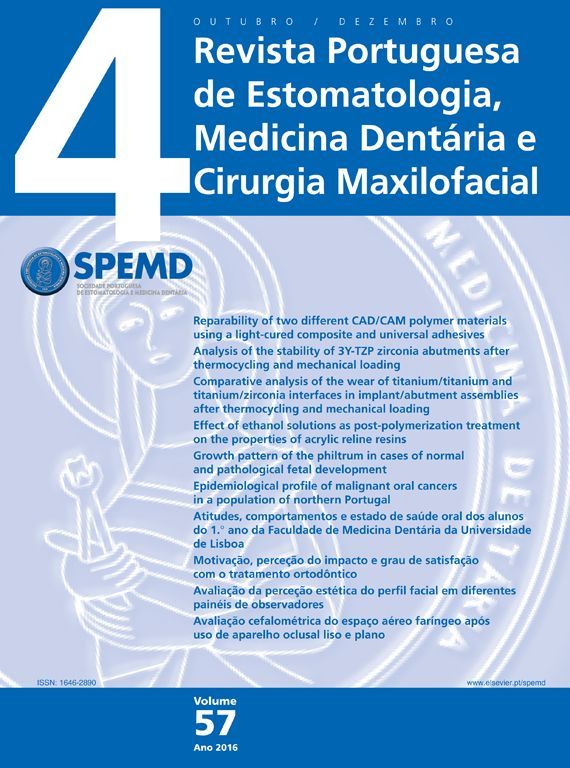

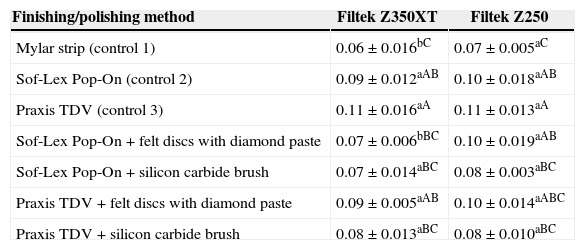

ResultsRa values differed significantly between composites and finishing and polishing systems tested, with significant interaction between these two variables (all p<0.05). These values were lower for Filtek Z350XT than for Filtek Z250 (Table 3) in control 1 and Sof-Lex Pop-On+felt discs with diamond paste groups. A rougher surface was also seen for Filtek Z250 in comparison with Filtek Z350XT by morphological analysis in control 1 and Sof-Lex Pop-On+felt discs with diamond paste groups (Fig. 1).

Surface roughness according to composite resin type and finishing/polishing method.

| Finishing/polishing method | Filtek Z350XT | Filtek Z250 |

|---|---|---|

| Mylar strip (control 1) | 0.06±0.016bC | 0.07±0.005aC |

| Sof-Lex Pop-On (control 2) | 0.09±0.012aAB | 0.10±0.018aAB |

| Praxis TDV (control 3) | 0.11±0.016aA | 0.11±0.013aA |

| Sof-Lex Pop-On+felt discs with diamond paste | 0.07±0.006bBC | 0.10±0.019aAB |

| Sof-Lex Pop-On+silicon carbide brush | 0.07±0.014aBC | 0.08±0.003aBC |

| Praxis TDV+felt discs with diamond paste | 0.09±0.005aAB | 0.10±0.014aABC |

| Praxis TDV+silicon carbide brush | 0.08±0.013aBC | 0.08±0.010aBC |

Values are presented as means±standard deviations. Different superscripted lowercase letters denote significant difference between composites tested with the same finishing and polishing systems (p<0.05). Different superscripted uppercase letters denote significant difference between finishing and polishing systems used with the same composite (p<0.05).

Scanning electronic photomicrographs showing a rougher surface for Filtek Z250 than Filtek Z350XT in control 1 and Sof-Lex Pop-On+felt discs with diamond paste groups. A: Sample of Filtek Z350XT allocated to control 1 group; B: Sample of Filtek Z250 allocated to control 1 group; C: Sample of Filtek Z350XT allocated to Sof-Lex Pop-On+felt discs with diamond paste group; D: Sample of Filtek Z250 allocated to Sof-Lex Pop-On+felt discs with diamond paste group.

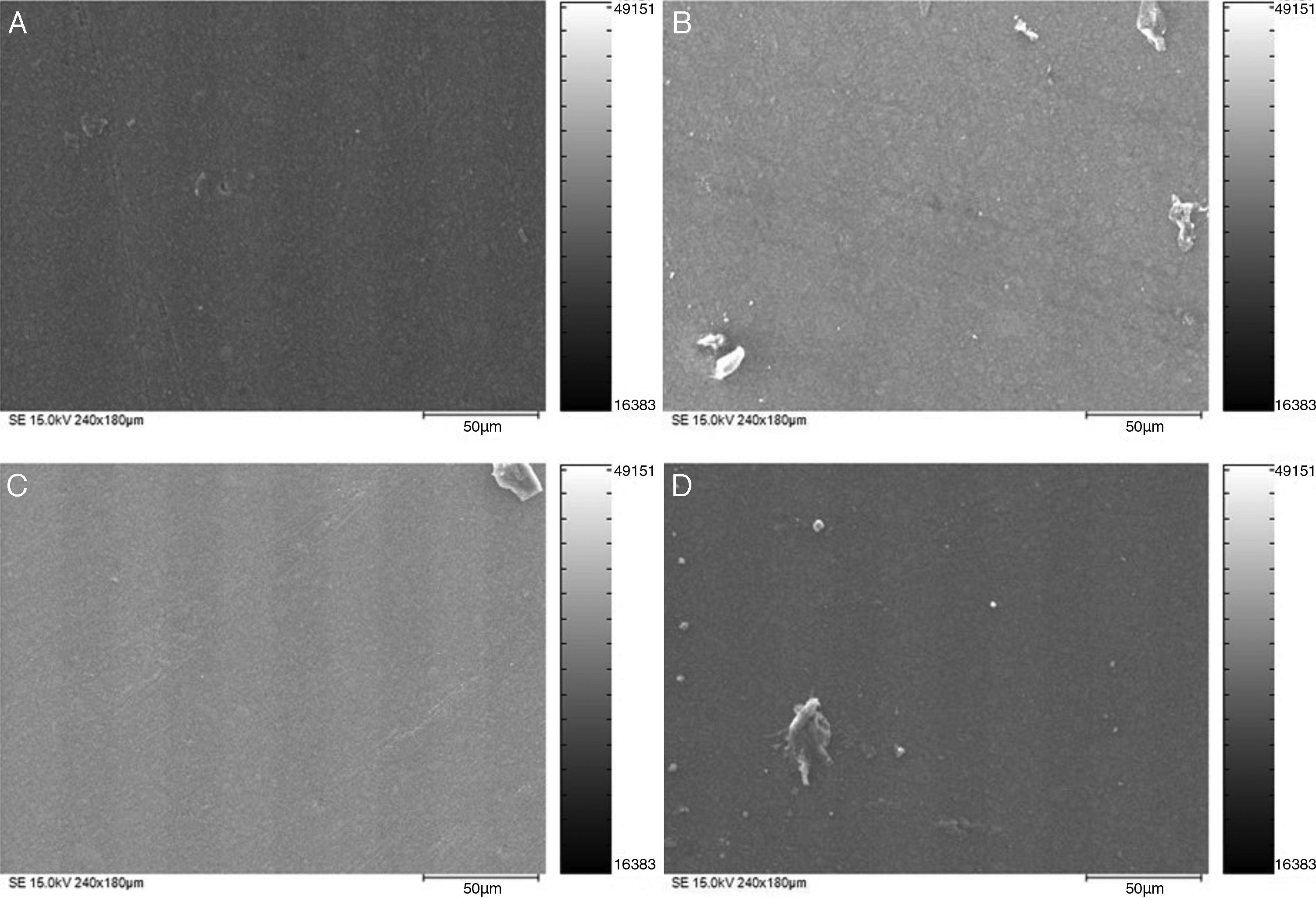

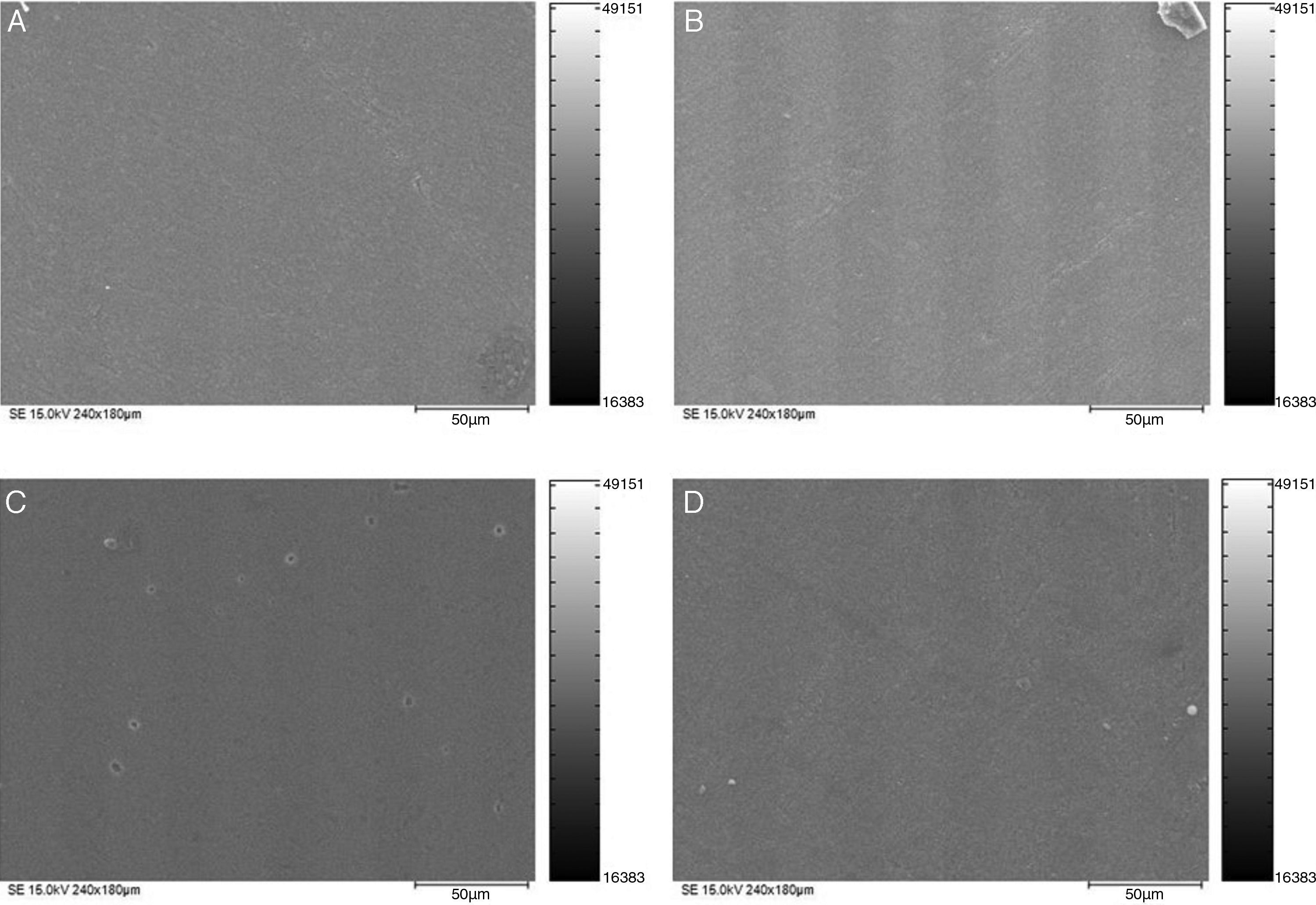

Among Filtek Z350XT groups, the best results were achieved with Sof-Lex Pop-On discs used in combination with the silicon carbide brush or felt discs with diamond paste, and Praxis TDV used with the silicon carbide brush (Table 3). These results were confirmed by morphological analysis (Fig. 2). Among Filtek Z250 groups, statistically lower Ra values were observed after polishing with a silicon carbide brush regardless of the previous finishing system, Sof-Lex Pop-On or Praxis TDV (Table 3). This pattern was confirmed by morphological analysis (Fig. 3).

Scanning electronic photomicrographs of Filtek Z350XT samples showing lower surface roughness for Sof-Lex Pop-On+silicon carbide brush (A), Sof-Lex Pop-On+felt discs with diamond paste (B), and Praxis TDV+silicon carbide brush (C) groups in comparison with Praxis TDV+felt discs with diamond paste (D).

Scanning electronic photomicrographs of Filtek Z250 samples showing lower surface roughness for Sof-Lex Pop-On+silicon carbide brush (A), Praxis TDV+silicon carbide brush (B) in comparison with Sof-Lex Pop-On+felt discs with diamond paste (C), and Praxis TDV+felt discs with diamond paste (D).

The hypothesis that tested that finishing techniques associated to the new polishing system carbide brush system would perform better for both composites was rejected, since the use of classical felt discs after alumina aluminum-oxide finishing discs provided similar surface roughness as the carbide brush for some groups. The importance of minimal surface roughness for the success of restorations has been well documented.3–5,8,9 Despite the evolution of dental composites, surface defects on these materials persist. Finishing and polishing studies have been performed to determine which technique achieves the best final results in terms of brightness and smoothness.10–12 However, no consensus has been established on the effectiveness of different systems used for finishing and polishing of composite resins.

The results of this study indicated that Filtek Z350XT, a recently introduced nanofilled dental composite, has less surface roughness compared with Filtek Z250, a microhybrid dental composite. In fact, Filtek Z350XT showed a smoother surface than Filtek Z250 when specimens were subjected to none of the finishing/polishing treatment (control 1 group), which was also found previously.13 This result can be explained by the smaller volume and less homogenous distribution of inorganic filler in microhybrid composites than in nanofilled composites.2

A surface composed of nanoparticles is theoretically less susceptible than a microhybrid material to the loss of particles (and thus increased surface roughness) caused by contact with abrasive finishing and polishing materials, due to the larger inorganic filler particles in the latter. However, in this study, only finishing and polishing with Sof-Lex Pop-On and felt discs with diamond paste produced significant differences between composites, with lower Ra values observed for Filtek Z350XT than for Filtek Z250.

In this study, both dental composites tested (nanofilled and microhybrid) showed greater surface smoothness when no finishing or polishing was performed (control group 1). Similarly, a previous study14 found lower surface roughness in unpolished dental composites than in those treated with various finishing and polishing techniques, suggesting that finishing and polishing cause surface damage. Other studies have produced similar results.15,16 However, finishing and polishing are essential to improve the chemical stability and mechanical properties of the resin surface,2 mainly in some areas, such as occlusal surface, where composite photoactivation under a Mylar strip is clinically unviable. In fact, a smooth and plain surface is necessary for roughness measurements through a 3D profilometer, therefore a Mylar strip was used to fabricate a plain sample.

Establishment of the best method of restoration finishing and polishing according to the composite used is important. In this study, the microhybrid Filtek Z250 showed the best behavior when polished with a silicon carbide brush regardless of the previous finishing aluminum-oxide disc (Sof-Lex Pop-On or Praxis TDV) used. The nanofilled Filtek Z350XT showed the best behavior when finished and polished with Sof-Lex Pop-On in combination with felt discs and diamond paste or Sof-Lex Pop-On or Praxis TDV in combination with a silicon carbide brush. Thus, unlike Filtek Z350XT, treatment with Sof-Lex Pop-On and felt discs with diamond paste did not increase the surface smoothness of Filtek Z250. Filtek Z350XT dental composite has nanoclusters of small inorganic particles that wear at a rate similar to that of the surrounding resin matrix. This property may explain the resin's sensitivity to both polishing techniques evaluated in this study. In contrast, microhybrid dental composites such as Filtek Z250 contain a wide distribution of inorganic particle sizes, with spaces between particles filled by organic matrix. Abrasion of these materials results in loss of resin around and between particles, causing protrusion of the particles and the appearance of peaks and valleys (i.e., roughness). In this view, surface roughness due to filler particle exposure caused by the use of aluminum-oxide discs was compensated by polishing with the silicon carbide brush in Filtek Z250 specimens. This brush has more abrasive components than diamond polishing paste, which is believed to result in smoother surfaces in these types of composite due to wearing of the projections exposed after finishing. Accordingly, the diamond polishing paste did not effectively achieve smoothness on the Filtek Z250 dental composite.

Although all finishing and polishing systems used in this study resulted in roughness values falling below the critical limit for bacterial adhesion (0.2μm),8 certain systems more effectively provided smooth surfaces for each resin type. Thus, when selecting finishing and polishing methods, dentists must consider composite characteristics, such as inorganic filler particle size.

Given the design of this study, the effects of intraoral conditions such as pH changes, salivary enzymes, and mechanical stress on the restorations were not taken into account. Comparative clinical evaluation of nanofilled and microhybrid dental composites treated with different finishing and polishing systems, including the recently introduced silicon carbide brush, could provide a more accurate indication of differences in the performance of these materials in vivo. However, this study provided evidence suggesting that the use of the silicon carbide brush with aluminum-oxide discs (Sof-Lex Pop-On or Praxis TDV) effectively reduced surface roughness in Filtek Z250 and Filtek Z350XT dental composites, and that the latter could also be polished with felt discs and diamond paste.

ConclusionsThe surface roughness of a composite resin depends on the composition of the restorative material and finishing and polishing techniques used. For Filtek Z350XT, the following finishing and polishing systems were more effective: Sof-Lex Pop-On+felt discs with diamond paste or silicon carbide brush and Praxis TDV+silicon carbide brush. For Filtek Z250, the following finishing and polishing systems were more effective: Sof-Lex Pop-On or Praxis TDV+silicon carbide brush.

Conflicts of interestThe authors have no conflicts of interest to declare.

Ethical disclosuresProtection of human and animal subjectsThe authors declare that no experiments were performed on humans or animals for this study.

Confidentiality of dataThe authors declare that no patient data appear in this article.

Right to privacy and informed consentThe authors declare that no patient data appear in this article.