This study aimed to evaluate the influence of the preheating of flowable composite resins on the color stability when exposed to drinking pigmented beverages.

MethodsWave (SDI) and Tetric N-Flow (Ivoclar Vivadent) were used. One hundred and twenty specimens (n=10) were photoactivated at different temperatures (25°C and 68°C). After curing, the specimens were immersed in distilled water for 24h (T0) and then subjected to cola drink, grape juice, and distilled water (control) for 7 days (T1). The color of the specimens was measured using a guide spectrophotometer Easy Shade (Vita Zahnfabrik) at T0 and T1 by means of the parameters of CIE-L*a*b*, and the overall color change after T1 (ΔE) was calculated. The data were analyzed by 3-way ANOVA and Tukey test (P<.05).

ResultsPreheated materials showed statistically significant lower color change after immersion in cola drink and grape juice (P<.01). Grape juice produced statistically the greatest color change for both materials tested regardless of the temperature (P<.01).

ConclusionThe preheating improved staining resistance of both flowable composites tested. Grape juice showed the highest stainability.

Este estudo objetivou avaliar a influência do pré-aquecimento de compósitos de baixa viscosidade na sua resistência à pigmentação diante de bebidas corantes.

MétodosOs compósitos Wave (SDI) e Tetric N-Flow (Ivoclar Vivadent) foram utilizados. Cento e vinte amostras (n=10) foram confeccionadas com as resinas em diferentes temperaturas (25°C e 68°C). Após a fotoativação, as amostras foram imersas em água destilada por 24 horas (T0) e, então, submetidas ao manchamento com refrigerante de cola, suco de uva ou água destilada (controle) por 7 dias (T1). A cor das amostras foi mensurada através de um espectrofotômetro (Easy Shade, Vita Zahnfabrik) em T0 e T1 utilizando-se os parâmetros do CIE-L*a*b*, de forma que a mudança de cor total após T1 (ΔE) foi calculada. Os dados foram analisador por meio do teste ANOVA a três fatores e o pós-teste de Tukey (P<0,05).

ResultadosOs materiais pré-aquecidos mostraram estatisticamente menor mudança de cor após imersão em refrigerante de cola e suco de uva (P<0,01). O suco de uva promoveu estatisticamente a maior mudança de cor para ambos os materiais testados, independentemente da temperatura (P<0,01).

ConclusãoO pré-aquecimento de resinas de baixa viscosidade melhorou sua resistência à pigmentação de ambos os materiais testados. O suco de uva mostrou o maior poder de manchamento.

Flowable composites were developed with the purpose of providing better handling, given that the material viscosity may affect negatively the chair time and the quality of the restoration.1 These materials have been used in permanent2 or provisory restoration repair,3 cervical lesion restoration,4 in small occlusal restorations,5 and as pit and fissure sealants.6 It is expected that flowable composites present good esthetic properties, which may be significantly jeopardized with the discoloration of these materials.

However, flowable composites are susceptible to acquiring several degrees of discoloration due to extrinsic and intrinsic factors.7–9 Aspects such as the degree of the conversion acquired by the organic matrix of a composite are critical factors for color stability.10 The explanation of this fact is that the monomers that were not converted generate products of colorimetric degradation that degrade the newly formed polymeric chain, facilitating the transition of solvents derived from the oral environment.11 As for the extrinsic factors, they surround the color of the used material, the darkest ones being less susceptible to absorb pigments,12 and the adsorption or absorption of derived exogenous substances, e.g., in food.9 Dark beverages such as grape juice and cola-based soft drinks may cause stains in various degrees in these materials, which vary with the composition of each of them.8

One technique that has been studied and developed to improve the physical and mechanical properties of the resinous materials is preheating before the photoactivation.13 It was shown that the preheating of composites induces the conversion of a higher quantity of monomers in polymers, reducing the quantity of free monomers and possibly avoiding the aforesaid inconveniences.13

In spite of certain existing assumptions, there are no studies that prove the efficacy of the preheating of flowable composite resins to increase resistance to color change after immersion in commonly consumed beverages, such as cola drink and grape juice. If preheated flowable composites show higher resistance to color change, they would have increased lifetime in the oral environment, reducing the necessity of changing for esthetic reasons.

This study aimed to evaluate the influence of the preheating of flowable composites on the color stability when exposed to cola drink, grape juice, and distilled water. The null hypothesis tested was that the preheating would not affect the color stability of the materials, regardless of the beverage.

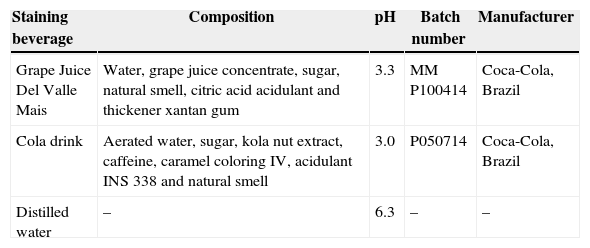

Materials and methodsThe Wave (SDI, Bayswater, Australia) and Tetric N-Flow (Ivoclar Vivadent, Schaan, Liechtenstein) flowable composites (A2 shade) were used in this study. The chemical components of the materials are listed in Table 1. Cola drink (Coca-Cola, Brazil), Del Valle grape juice (Coca-Cola, Brazil), and distilled water (control) were used as staining beverages. The pHs of all beverages were verified by a pH meter (NT-PHM/NTPHP, Nova Técnica, Piracicaba, SP, Brazil) and are shown in Table 2.

Commercial name, composition, batch number and manufacturer of materials used in the study.

| Material | Composition by weight | Batch number | Manufacturer |

|---|---|---|---|

| Wave | Functional methacrylate ester (35%) and inorganic particles (65%) | 130110NZ | SDI, Bayswater, Australia |

| Tetric N-Flow | Dimethacrylates (36%) (including TEGDMA), particles (63%) (barium oxide, ytterbium trifluoride, highly disperse silica and mixed oxides) and pigments, catalysts and stabilizers (1%) | T00421 | Ivoclar Vivadent, Schaan, Liechtenstein |

TEGDMA: triethylene glycol dimethacrylate.

Staining solutions used in the study.

| Staining beverage | Composition | pH | Batch number | Manufacturer |

|---|---|---|---|---|

| Grape Juice Del Valle Mais | Water, grape juice concentrate, sugar, natural smell, citric acid acidulant and thickener xantan gum | 3.3 | MM P100414 | Coca-Cola, Brazil |

| Cola drink | Aerated water, sugar, kola nut extract, caffeine, caramel coloring IV, acidulant INS 338 and natural smell | 3.0 | P050714 | Coca-Cola, Brazil |

| Distilled water | – | 6.3 | – | – |

One hundred twenty cylindrical samples (5mm diameter×1mm thickness) were prepared using Teflon molds, according to the flowable composite (Wave and Tetric N-Flow), the temperature (25°C for room temperature, and 68°C for preheated), and the staining beverage (cola drink, grape juice, and distilled water) used (n=10).

To preheat the flowable composites, each tube of both flowable composites was kept at room temperature (25°C) or in an incubator (SL 101/E, Solab, Piracicaba, SP, Brazil) at 68°C for 2h before samples confection.14 The Teflon mold was set on a glass plate, and the material was inserted. The final composite temperatures before photoactivation were measured with an infrared thermometer (MS6530H, Commercial Electric, Atlanta, USA). A thin (0.5mm thick) glass slide was positioned on the composite, which was photoactivated for 20s using a light emitting diode (LED) device (Coltolux LED, Coltène, Switzerland – 1200mW/cm2).

After the photoactivation, the samples were removed from the Teflon molds, immersed in distilled water at 37°C, and placed into a dark container for 24h.

The initial color of the samples was obtained after 24h water storage (T0) on the top surface using a portable spectrophotometer15 (Easy Shade, Vita Zahnfabrik, Bad Säckingen, Germany). The samples were previously washed (individually) in running water for 10s, dried with absorbent paper, and positioned against a flat white porcelain background. A silicon mold (Futura AD, DFL, Rio de Janeiro, Brazil) was fabricated, covering the whole sample to standardize the position of the device tip on the sample surface as well as to impair light penetration during the measurement. A central hole on the top surface of the mold was made to allocate the device tip. Then, the samples were immersed in 1.5mL of each beverage (cola drink, grape juice, and distilled water) at 37°C for 7 days (T1), which were daily changed, and another color measurement was made.

The samples were previously washed (individually) in running water for 10s, dried with absorbent paper, and positioned against a flat white porcelain background. The readings were performed in triplicate for each sample (the mean per specimen was considered), and the colorimeter was calibrated after performing each 10 measurements per group. The color readout followed the CIE-L*a*b* system (Comission Internationale de I’Éclairage). The L* (luminosity), a* (axis green-red), and b* (axis yellow-blue) values were registered, and the total color change (ΔE) after T1 was calculated using Hunter's equation, ΔE=[(ΔL*)2+(Δa*)2+(Δb*)2]1/2.

After verifying normal distribution of the data using the Kolmogorov–Smirnov test (P>.05), 3-way ANOVA and Tukey tests (P<.05) were performed. The ASSISTAT Beta 7.6 software was used to perform statistical tests.

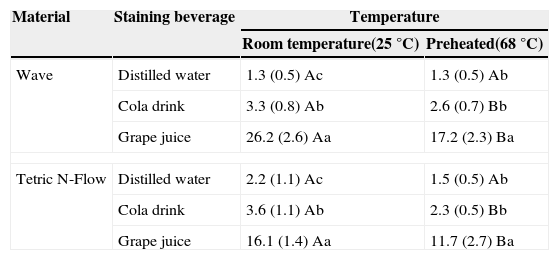

ResultsThere were no statistically significant differences between the materials (P>.05). However, there were statistically significant differences between the temperatures (P<.01), among solutions (P<.01), and in the interaction among materials×temperature×solutions (P<.01). The comparison between the groups is shown in Table 3. In both materials, preheating favored a lower color change caused by cola drink and grape juice, whereas it had no effect for the control solution (distilled water). For both materials at room temperature (25°C), grape juice produced the greatest color change values (ΔE), whereas distilled water produced the lowest ones. For preheated materials (68°C), grape juice also generated the greatest color change values (ΔE), whereas cola drink provided the same change as the control solution.

Color change (ΔE) according to the materials, temperatures and solutions evaluated.

| Material | Staining beverage | Temperature | |

|---|---|---|---|

| Room temperature(25°C) | Preheated(68°C) | ||

| Wave | Distilled water | 1.3 (0.5) Ac | 1.3 (0.5) Ab |

| Cola drink | 3.3 (0.8) Ab | 2.6 (0.7) Bb | |

| Grape juice | 26.2 (2.6) Aa | 17.2 (2.3) Ba | |

| Tetric N-Flow | Distilled water | 2.2 (1.1) Ac | 1.5 (0.5) Ab |

| Cola drink | 3.6 (1.1) Ab | 2.3 (0.5) Bb | |

| Grape juice | 16.1 (1.4) Aa | 11.7 (2.7) Ba | |

Means followed by different capital letters indicate statistically significant differences between the temperatures for the same material and the same solution (P<.05). Means followed by different lower case letters indicate statistically significant differences among the staining beverages for the same material and the same temperature (P<.05).

The null hypothesis tested in this investigation was rejected since preheated materials showed increased staining resistance to cola drink and grape juice than materials at room temperature. An increase in the degree of conversion is expected for preheated resin-based materials, especially flowable composites.16,17 The high temperature decreases the material viscosity, increasing the frequency of collision between nonreactive groups and free radicals and enhancing its radical mobility, resulting in additional polymerization and higher conversion.18 A polymer with a low degree of conversion presents increased formation of colorimetric degradation products and higher penetration of solvents from the oral environment in the polymer chain.19,20 Higher water sorption can also hydrolyze the silane around filler particles, causing microcracks that would allow pigment penetration and subsequent color change.21 Thus, it is reasonable to attribute the greater color stability of the preheated materials to a higher degree of conversion.

In clinical conditions, the temperature at which the material is inserted in the tooth and the time delayed to insert, model, and photoactivate the material in the tooth should be considered. However, studies have shown that even if the composite cools to about 40°C, benefits may still be achieved compared to at-room-temperature composites.22 Furthermore, recent studies investigated the effects of preheating composites at temperatures up to 68°C and placing them directly on dentin.23,24

Previous studies have shown that the highest color changes were observed when the materials were immersed in red wine.24–26 However, in an attempt to investigate beverages consumed by children, who are prone to receive a pit and fissure sealant with flowable composite in comparison with adult individuals, grape juice was used in this study instead of red wine.

In this study, the samples immersed in grape juice showed the highest color change values (ΔE), regardless of the temperature before the photoactivation. ΔE values higher than 3.3 are easily perceived by the human eye and clinically unacceptable.27 Probably the low pH of the grape juice affected the resin surface, increasing pigment absorption.27,28 Also, the ability of the composite to absorb fluids is strongly related to the nature of the material. Hydrophobic materials have low water sorption but can be stained by hydrophobic solutions, whereas hydrophilic materials were stained with hydrophilic substances in aqueous solutions.21 The color of grapes comes from the anthocyanin, which is a water-soluble vacuolar pigment that presents hydrophilic character.29 Since TEGDMA has high water affinity20,30 and is a common component of flowable composites, one may presume that an increased absorption of anthocyanin occurred, leading to the highest color change on the materials.

Although the cola drink has a low pH, which would damage the surface integrity of the materials, this beverage did not produce similar color change to the grape juice. The preheated specimens immersed in cola drink showed ΔE values similar to the control group (distilled water), which were clinically acceptable (1.0<ΔE<3.3).27 Beverages with similar pH but different main acids can generate different damage patterns on structures.31 The cola drink contains carbonic and phosphoric acids, whereas grape juice contains citric acid, so the different acids found in both beverages could explain this find. Even though a continuous immersion time of composite restoration for 7 days into pigmented solutions is not usually common in clinical conditions, this method has been previously used in vitro.32 In fact, the continuous but short immersion time of 7 days might be interpreted as an accelerated method to staining the materials.

The type of resin matrix used in the material has also been shown to play an important role in staining susceptibility.21 Manufacturers of the materials used in this study did not provide enough information concerning their chemical components. However, it may be inferred that chemical components of both flowable composites tested had similar overall staining susceptibility to the beverages evaluated since there were no statistically significant differences on the color change between materials.

Dental restorative materials are continuously exposed to saliva, drinks, and food pigments. The importance of establishing their susceptibility to color change is because the material discoloration can be a reason for the replacement of tooth restorations in esthetic areas. Although an incubator has been used in this investigation, a clinically viable device (Calset, AdDent Inc., Danbury, CT, USA) should be employed for clinicians daily to preheat flowable composites.

It is important to emphasize that the solutions tested in this study do not represent all beverages to which restorative materials can be exposed in the oral environment. Further investigations are necessary to evaluate the color stability of preheated flowable composites when exposed to other beverages and measuring individual color parameters, such as luminescence, and gloss. Moreover, clinicians should be advised not to attempt to overheating, that is, the entire composite tube should not be heated several times, since reheating may affect material properties. On the other hand, only a low amount of the material that will be used should be heated using specific composite heater devices such as Calset (Calset, AdDent Inc, Danbury, CT, USA).

ConclusionPreheating of flowable composites increased the color stability when exposed to cola drink and grape juice. Grape juice produced the greatest color change among the tested beverages.

Ethical disclosuresProtection of human and animal subjectsThe authors declare that no experiments were performed on humans or animals for this study.

Confidentiality of dataThe authors declare that no patient data appear in this article.

Right to privacy and informed consentThe authors declare that no patient data appear in this article.

Conflicts of interestThe authors have no conflicts of interest to declare.