This study explores the perceptions and implications of a large manufacturing company as it shifts toward a circular economy. It devises a guiding framework to facilitate this transition by delving into key focus areas, informed by a systematic literature review. From this review emerges a multi-level readiness framework tailored to facilitate the transition to a circular economy. This framework is validated through a case study conducted in the heavy-duty vehicle industry. The proposed readiness framework encapsulates four key focus areas: 1) the ecosystem of external partners, 2) the customer and the business model, 3) the company's culture and internal capabilities, and 4) design and product development. Moreover, the framework delineates five levels of readiness progression within each focus area. Strategies and indispensable activities essential for transitioning to a circular economy are outlined. The suggested hands-on readiness framework advocates holistic and cross-functional management approaches to navigate the transition toward a circular economy. The readiness status for the transition ranges from initial developmental stages to full circularity, with each level outlining actionable pathways incorporating specific actions and strategies.

Circularity has emerged as one of the most promising avenues for fostering sustainable development (Centobelli et al., 2020; Chirumalla, 2023; Mas-Tur et al., 2019). However, a lack of consensus remains regarding a comprehensive framework to guide manufacturing companies in effectuating a systematic transition toward a circular economy. Over the past decade, the concept of the circular economy has gained considerable traction globally, offering potential solutions to environmental challenges by departing from the linear take–make–dispose model prevalent in traditional manufacturing (Blomsma & Brennan, 2017; Amir et al., 2022). In Europe, the European Commission has been actively promoting the transition of all manufacturing sectors toward circularity, recognizing it as a significant opportunity to mitigate waste, enhance competitiveness, shield businesses from the constraints of finite resources and fluctuating prices, and foster innovation (European Commission, 2015, 2020). Projections suggest that embracing the circular economy could result in a substantial 48 % reduction in carbon emissions by 2030 (McKinsey & Company, 2016), thus safeguarding the environment and the integrity of its ecosystems.

Despite the considerable potential impact of adopting circular economy principles, devising and executing a feasible pathway remains a formidable challenge for conventional industrial manufacturing companies (Chhimwal et al., 2022; Jaeger & Upadhyay, 2020). Specifically, transitioning from a linear to a circular economy necessitates a comprehensive overhaul of how companies structure and coordinate all facets of their developmental, managerial, and operational endeavors along with their supply chains, business models, and customer relationships (Bjornbet et al., 2021; Frishammar & Parida, 2019; Song et al., 2024). This transition is further compounded by the inherent complexity and divergent interpretations of the circular economy concept among various stakeholders (Corona et al., 2019; Corvellec et al., 2022). This encompasses both internal stakeholders (e.g., R&D, marketing, engineering, production, logistics) and external stakeholders (e.g., customers and suppliers), thereby resulting in ambiguous implementation strategies across diverse industries. In this context, a systematic examination of the circular economy literature conducted by Kirchherr et al. (2017) revealed that even the term "circular economy" lacks a universally agreed definition. Their study identified 114 distinct definitions across academic journals, policy documents, and reports (Kirchherr et al., 2017). The outcome of this study defines the circular economy as “an economic system that replaces the ‘end-of-life’ concept with reducing, alternatively reusing, recycling and recovering materials in production/distribution and consumption processes. It operates at the micro level (products, companies, consumers), meso level (eco-industrial parks) and macro level (city, region, nation and beyond), to accomplish sustainable development” (p. 229).

Research has proposed various frameworks, models, and tools to assist companies in transitioning toward circularity (Bocken et al., 2019; Blomsma et al., 2019; Chirumalla et al., 2022; Dawson & Spedding, 2010; Frishammar & Parida, 2019; Mohamed Sultan et al., 2017; Mendoza et al., 2017; Thorley et al., 2022). Each tool exhibits distinct characteristics and features conducive to the transition to a circular economy. For instance, maturity models assessing materials' recyclability levels can inform the development of a novel scientific approach to prioritize the recycling of end-of-life products within a circular economy framework (Mohamed Sultan et al., 2017). Frameworks grounded in discrete simulation events can support change management initiatives, particularly focusing on environmental capabilities and processes (Dawson & Spedding, 2010). Furthermore, frameworks aimed at promoting the adoption of circular economy principles should integrate multiple perspectives, such as back-casting and eco-design methodologies (Mendoza et al., 2017), and involve diverse stakeholders to foster a mutually beneficial scenario encompassing the needs of stakeholders, the environment, and society (Chirumalla et al., 2022). Additionally, checklists and roadmaps have been developed to facilitate and encourage the transition to circular practices and innovations in business models in large manufacturing companies (e.g., Bocken et al., 2019; Frishammar & Parida, 2019).

A holistic perspective on understanding the circular economy holds the potential to enhance the likelihood of its successful development and implementation in companies by integrating corporate decision making, operations, and systems thinking (Bjornbet et al., 2021; Chirumalla et al., 2022; Geissdoerfer et al., 2017; Lozano et al., 2021; Mendoza et al., 2017; Mangers et al., 2021; Sgroi et al., 2018). Indeed, avoiding a narrow focus on individual practices and knowledge silos is paramount in embracing a comprehensive and integrated approach (Ünal et al., 2019). Failure to adopt such an approach may pose risks to the socially, environmentally, and economically beneficial outcomes of circular economy implementation efforts (Bjornbet et al., 2021; Baldassarre & Calabretta, 2024; Frishammar & Parida, 2021). A holistic approach, from a company perspective, entails a comprehensive and interconnected methodology to address challenges or pursue objectives, encompassing the entirety of the organization and its various interrelated components (e.g., Friant et al., 2020; Lozano et al., 2021). In the context of implementing a circular economy, this involves not only examining individual aspects of the business but also considering their interdependencies and synergies (e.g., Bjornbet et al., 2021; Chhimwal et al., 2022; Frishammar & Parida, 2019; Lieder & Rashid, 2016; Song et al., 2024). This demands consideration of key dimensional areas within a company, such as product design, production, supply chain, customers, and corporate culture, employing an integrated approach across all stages.

Numerous researchers have underscored the importance of a holistic approach toward the circular economy (e.g., Blomsma et al., 2019; Lozano et al., 2021; Reich et al., 2023), emphasizing considerations of different waste hierarchy levels and macro‑meso-micro levels (e.g., Blomsma et al., 2019), integration of economic and environmental dimensions, and collaboration (Lozano et al., 2021), as well as the integration of material flow and supply domain, environmental, and societal aspects (Reich et al., 2023). Hence, a supporting methodology or tool that embraces such an approach represents a promising option to strategically guide manufacturing companies toward introducing a circular economy into their existing traditional practices while ensuring the sustainability component is not neglected.

In traditional manufacturing companies, conventional development and innovation endeavors typically adhere to process-based models involving cross-functional teams (Song et al., 2024; Ungureanu et al., 2021). Numerous researchers have underscored the importance of cross-functional collaboration in successfully implementing circular economy initiatives (Diaz et al., 2022; Pigosso & McAloone, 2021; Amir et al., 2022). In light of this, a guiding framework is needed that can facilitate a cross-functional readiness assessment of a traditional manufacturing company's status across key focus areas in the transition toward circularity. This framework should assist companies to employ a cross-functional readiness approach, addressing key focus areas and the associated activities in these areas and adopting a long-term strategic perspective well into the future. The underlying assumption is that key focus areas guide cross-functional teams on “where” to concentrate their efforts, while the activities delineate “how” to address them systematically. Such an integrated assessment from multiple perspectives enables companies to adopt a "helicopter view" of the situation and contemplate the systematic changes required for the transition.

This study aims to develop a holistic framework for traditional manufacturing companies to transition toward a circular economy. This framework will integrate cross-functional collaboration and readiness, offering a systematic approach to assess key focus areas and implement corresponding activities aligned with long-term strategic goals. This framework aims to assist companies in visualizing their progress toward circularity by adopting suitable activities and strategies across various cross-functional business areas.

This study commenced with a systematic literature review, culminating in developing a holistic and multi-level readiness framework to facilitate the transition to a circular economy. Subsequently, this model underwent exploration and validation through a case study conducted in the heavy-duty vehicle manufacturing industry. These findings contribute to the circular economy literature by introducing a practical, hands-on, multi-level readiness framework to address key focus areas and activities within traditional manufacturing companies. Moreover, this study contributes to the theoretical discourse by emphasizing the significance of holistic and cross-functional management approaches in navigating the transition toward a circular economy.

The remainder of this paper is organized as follows: Section 2 explains the research approach and context, offering a detailed depiction of the research process. Section 3 establishes the theoretical framework by delineating key concepts and presenting the multi-level readiness framework for transitioning toward a circular economy. Section 4 presents the empirical findings, encompassing the key focus area, strategies, and activities pertinent to the transition to a circular economy. Section 5 discusses the theoretical and practical implications derived from the results. Finally, Section 6 concludes by providing an overview of the study's limitations and suggesting directions for future research.

Research methodologyResearch approachThis study aims to explore the key focus areas and activities pertinent to the transition from a linear to a circular economy in a large manufacturing company and also to investigate practical approaches to implementing circularity in its operations. It focuses on the contemporary phenomenon of identifying key focus areas and activities for this transition in a real-life context where clear boundaries between the phenomenon under investigation and its contextual environment may not be evident (Yin, 2009). Therefore, a case study research approach is deemed appropriate. Case studies employ an inductive investigative strategy, yielding richly descriptive outcomes (Merriam & Tisdell, 2016). Furthermore, a case study is better suited than surveys or experimental studies (Yin, 2009) due to the complexities involved in framing, understanding, and planning an appropriate strategy for transitioning toward a circular economy in a well-established company.

Case companyA case study was selected using purposeful sampling. This is a systematic and deliberate method for selecting cases rich in information, making it ideal for conducting an in-depth investigation (Patton, 2002). The selection criteria for the case were guided by the study's purpose, which emphasizes four key aspects: (1) the context of transitioning from a linear to a circular economy and the establishment of clear goals for this transition, (2) the intention to identify key focus areas necessary for the transition in a cross-functional setting, (3) the plan to manage circular readiness and associated activities through a systematic approach, and (4) the choice of a company with an established traditional manufacturing base and a global presence.

Based on these criteria, a large manufacturing company operating in the heavy-duty vehicle and construction equipment industry was identified as a suitable candidate. The company stands among the world's leading manufacturers of articulated haulers, wheel loaders, excavation equipment, compact construction equipment, and road development machines. Its services encompass financing, rental, servicing, and used equipment offerings. Presently, the company maintains a workforce of approximately 1500 employees across 85 countries, with its broader corporate group encompassing around 95,000 employees. With a complex organizational structure, the company relies on an extensive global network of suppliers and dealers. Aligned to its commitment to environmental sustainability and the objectives of the Paris Agreement, the case company has pledged to significantly reduce its carbon footprint. As part of its science-based target goals, the company aims to achieve net-zero value chain emissions by 2040, with substantial reductions targeted as early as 2030. The company's product range includes electric compact machines and larger mid-size excavators and wheel loaders, marking a significant step towards its ambitious goal of achieving 100 % fossil-free operations by 2040.

Additionally, the following reasons were considered in selecting this company as a suitable candidate for our study:

- •

Through various initiatives, including servitization, electrification, circular economy, and autonomous solutions, the company has showcased a strong commitment to environmental sustainability and circular economy principles.

- •

The company profoundly embraces the triple bottom-line framework proposed by Elkington (1999), prioritizing environmental sustainability, social responsibility, and economic viability in its operations.

- •

The company has established clear and defined sustainable targets to be achieved in both the short and long term, underscoring its proactive approach to sustainability.

- •

The company is interested in adopting a strategic framework to facilitate a comprehensive understanding of past efforts and identify future steps required to systematically implement the transition toward a circular economy across the organization.

The research process followed in this study can be divided into five phases: 1) exploration of company needs and problematization, 2) performance of a systematic literature review, 3) development of a multi-level readiness framework to facilitate the transition to a circular economy, 4) empirical data collection and validation of the framework, and 5) data analysis and conclusions.

- -

Exploration of company needs and problematization. In this exploratory phase, the researchers were in close contact with the company to thoroughly understand its approach to the theme of sustainability and circularity and to frame the different needs and perspectives of high-level company management regarding circularity. Informal discussions, observations, and immersion in the industrial context are pivotal in this phase.

- -

Performance of a systematic literature review. A systematic literature review was conducted to extensively retrieve and analyze state-of-the-art knowledge on the transition to a circular economy and its readiness models and tools in large manufacturing companies.

- -

Development of a multi-level readiness framework to facilitate the transition to a circular economy. The conceptual framework is developed using the retrieved and analyzed articles based on a pattern-matching technique, as provided in Appendix B. The framework presents four key focus areas and a set of activities and strategies that can be implemented on a scale from 1 to 5, with a growing transition progression.

- -

Empirical data collection and validation of the framework. During this phase, semi-structured interviews were carried out to gain deeper insights (see Appendix C for the interview protocol) and a greater understanding of the transition toward a circular economy from a practical perspective, as well as to test and validate the conceptual framework with the help of key people who play strategic managerial roles in the company.

- -

Data analysis and conclusions. In the final phase, a discussion is undertaken on the entire research process with particular reference to the key findings and conclusions.

A systematic literature review establishes the theoretical framework for the study and provides a solid foundation for contributing to the knowledge base (Merriam & Tisdell, 2016). In this study, the review aimed to highlight the most relevant scientific publications in the field of circular economy and to examine different aspects and approaches that should be considered when initiating and engaging in a transition. Such aspects and approaches were later synthesized in a thematic analysis and subsequently presented as a conceptual model. The Scopus database was used as a primary source for the literature search because it covers engineering and business areas and includes journals related to the circular economy. The database searched for published articles with no limitations on specific years. The decision to include research with no time limit was due to the topic's novelty, which meant a relatively contained number of publications. The following search strings were used in the database:

TITLE-ABS-KEY (“Circular economy” OR “business models” OR “circularity” OR “circular*”) AND TITLE-ABS-KEY (“roadmap” OR “readiness levels” OR “maturity models” OR “readiness” OR “implementation stages”) AND (LIMIT-TO (DOCTYPE) “ar”)) AND (LIMIT-TO (SUBJAREA, “ENGI”) OR LIMIT-TO (SUBJAREA, “BUSI”)) AND (LIMIT-TO (LANGUAGE, “ENGLISH”)).

Inclusion and exclusion criteria and a transparent selection protocol retrieved only the literature relevant to the research topic. Only articles on manufacturing industries were included, and research was conducted in all countries in all years to gain knowledge irrespective of geographical location. English was the sole language employed to avoid mistakes and misunderstandings that could occur from using translation software. Only journal articles and review articles were included. Documents such as conference papers and non-peer-reviewed research materials were excluded, as were research areas too far from the focus (e.g., arts and humanities, agricultural and biological sciences, chemistry, physics, health sciences).

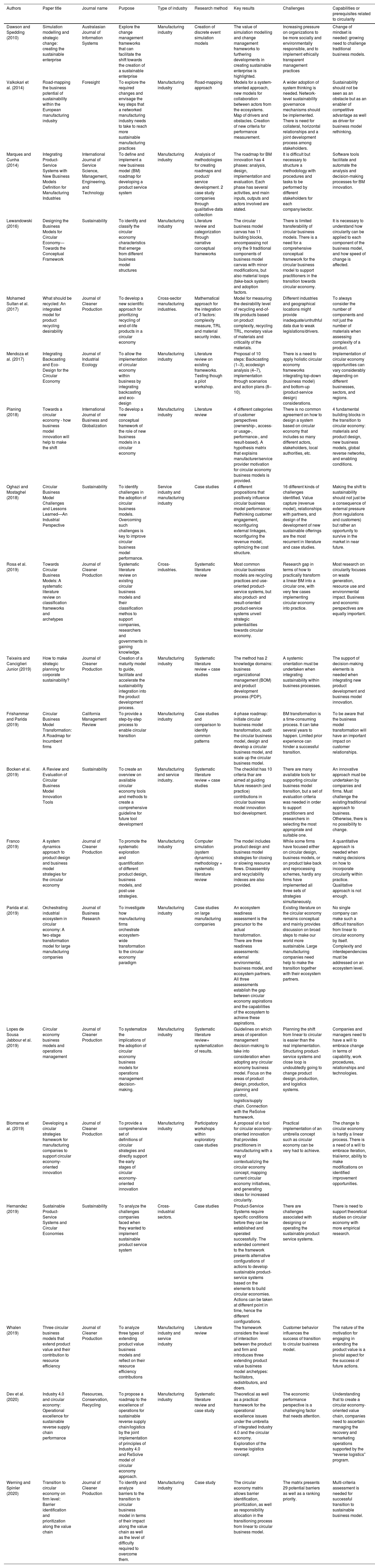

Initially, 228 articles were selected based on a title analysis. Those irrelevant to the chosen theme and focus area were excluded, reducing the number of articles to 45. The articles’ abstracts were then analyzed according to the same criteria, which decreased the number to 23. Lastly, the full texts of papers were analyzed, reducing the number to 12 articles. Eight additional papers were identified by looking at references and citations, resulting in a total of 20 selected articles. Appendix A includes an overview of the retrieved articles and an extensive analysis of the paper's purpose, type of industry, research method, description of key results, challenges mentioned, and capabilities or pre-requisites related to circularity.

During the systematic literature review, the following features, representing key characteristics or attributes, were considered essential to develop a valid conceptual framework:

- •

First, the feature of "following a holistic approach to the theme of circularity" underscores the importance of considering circular economy principles from a comprehensive perspective, as advocated by previous studies (Bocken et al., 2019; Chirumalla et al., 2022; Lozano et al., 2021; Mendoza et al., 2017). This approach contrasts with narrower, single-thematic approaches adopted in prior research efforts, emphasizing the need for a broader, interconnected understanding of circularity.

- •

Second, "employing an in-depth analysis of the most recurrent key focus areas" highlights the systematic examination of prevalent themes and topics identified in the literature. This entails pinpointing and analyzing the most frequently discussed areas where interventions are needed to facilitate the transition to a circular economy, providing a comprehensive understanding of the key focus areas.

- •

Lastly, the feature of "manifesting an extensive range of possible activities and strategies" emphasizes the exploration and documentation of a diverse array of actions and approaches available for addressing the key focus areas identified. This includes a broad spectrum of potential activities and strategies gathered from the literature (e.g., Blomsma et al., 2019; Mendoza et al., 2017; Planing, 2018; Parida et al., 2019), offering insights into practical implementation tactics for achieving circularity objectives in various organizational contexts.

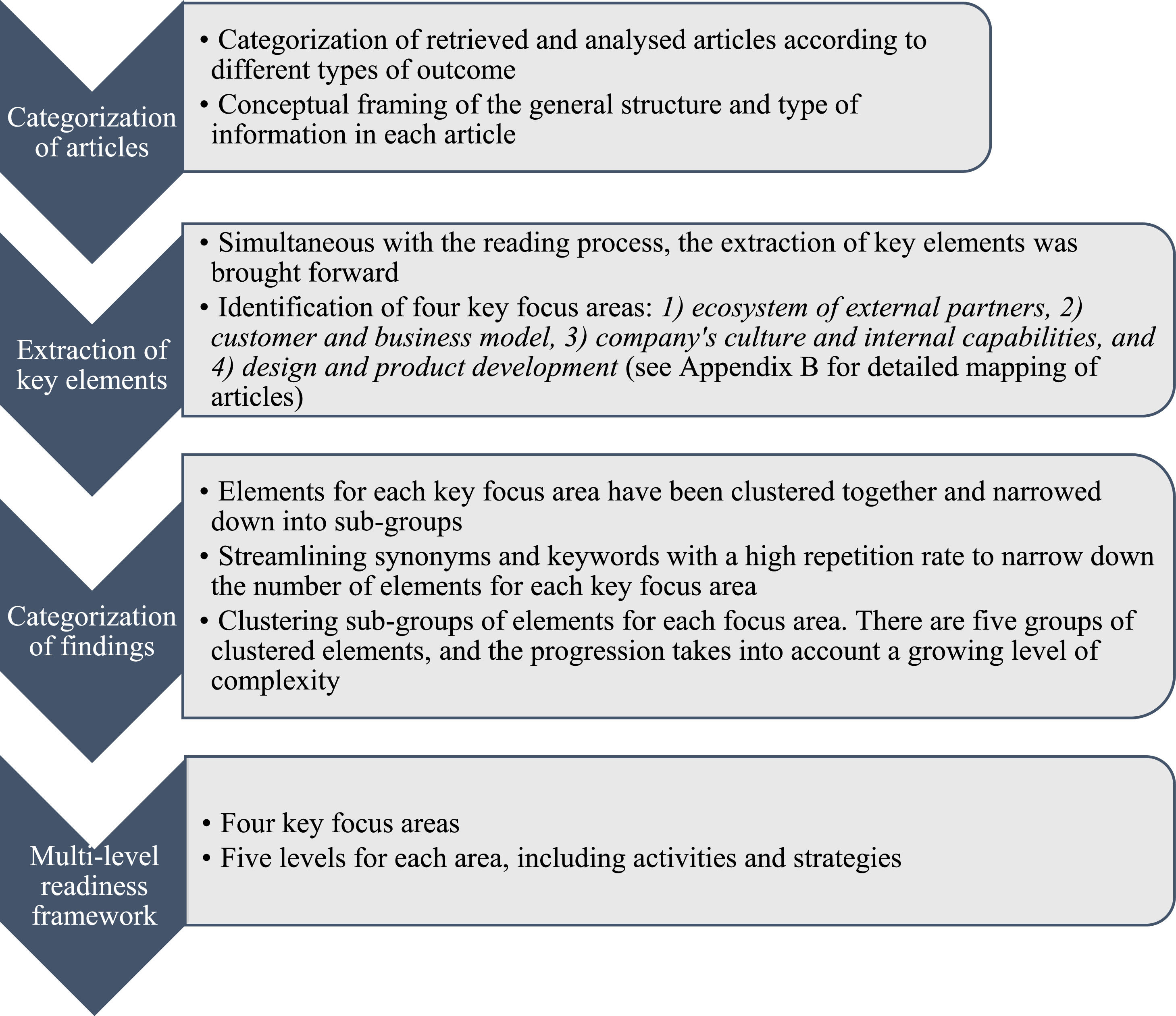

The following four-step process (see Fig. 1) was used during the analysis to develop the conceptual multi-level readiness framework for transitioning toward a circular economy.

Data collectionThe research approach to empirical data collection is based on observations and interactions between the researcher and the research strategy manager of the company, as well as with other key people who play strategic roles in the company There were approximately 30 face-to-face meetings over 4 months. Empirical data play a pivotal role in two distinct phases of this research: 1) observations and informal interactions are conducted, especially at the beginning of the study, during the exploration of company needs and problematization, and 2) semi-structured interviews are conducted after the development of the conceptual multi-level readiness model.

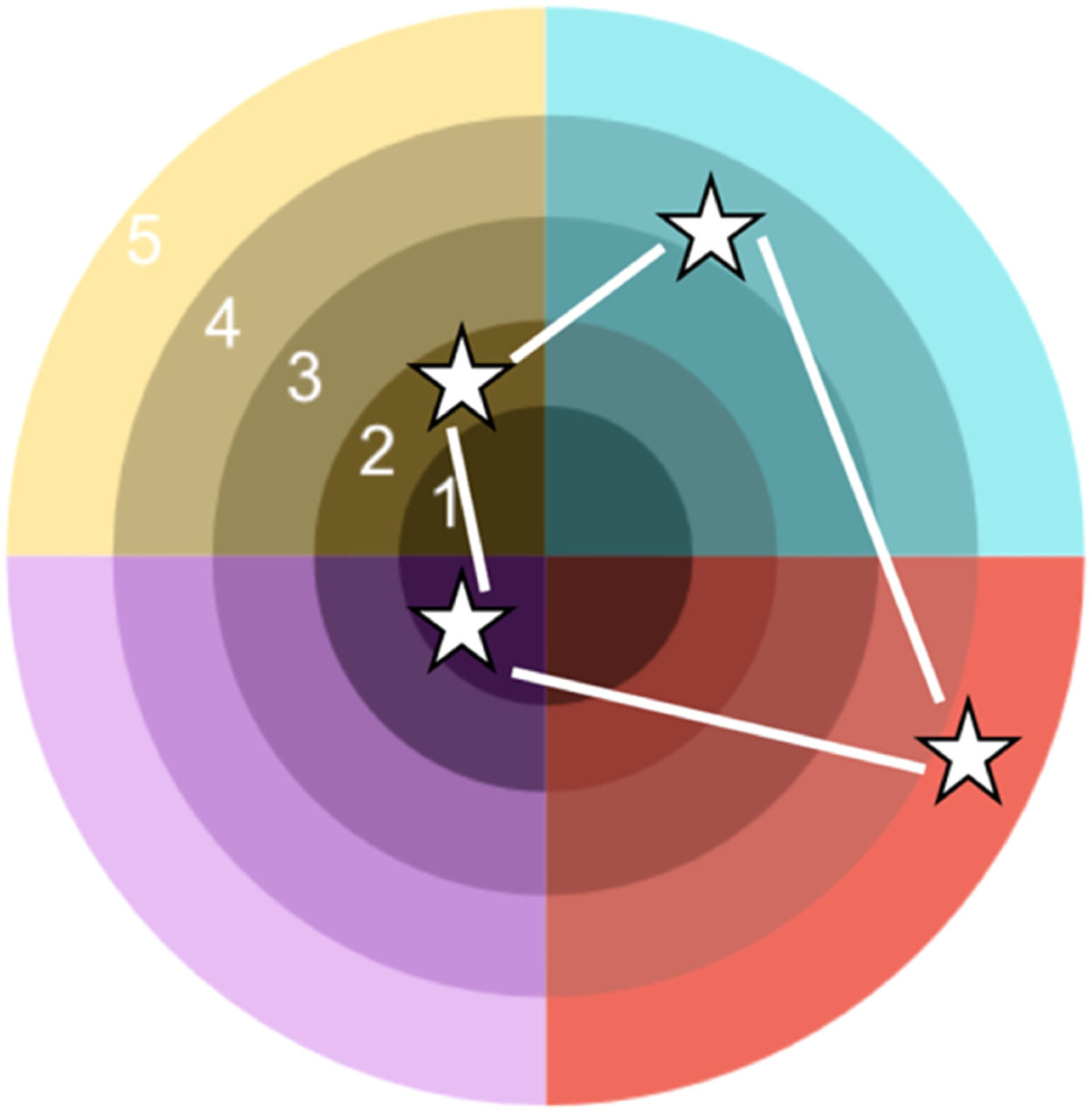

Ten informants were selected for the interviews, as shown in Table 1. The informants were selected on the basis of: i) the number of years of experience working in the company (i.e., a minimum of 8 to 10 years); ii) the current job profiles, which play a critical cross-functional role in the transition from a linear to a circular economy; and iii) the relevant job history related to the circular economy transition. An interview protocol (see Appendix C) was adopted with all informants to ensure the case study's reliability (Yin, 2009). Of the ten interviewees, eight were from the case company. In contrast, two were selected from a Swedish public research institute as experts exercising the roles of senior researcher and project manager. The decision to include two experts from outside the case company stemmed from the desire to give further validity to the study, given that the research focus of the experts is to enhance Swedish capabilities in a circular economy. It is important to include the perspective of professionals close to other companies in the same industry and focus on the transition to circularity. The interview protocol was structured as follows: 1) general questions on the informant's experiences and perceptions of the circular economy concept and the transition, 2) discussion on strategies and activities that are needed or can be implemented, 3) discussion on the proposed multi-level readiness framework, and finally 4) suggestions for further improvement of the framework and its implementation.

Details of interviewed informants.

The semi-structured interviews were recorded and transcribed. The notes and insights collected during the interview process were summarized. The data analysis process, which involves consolidating, reducing, and interpreting what informants have said, often starts during the data collection phase (Merriam & Tisdell, 2016). The researcher makes sense of what has been said and discussed as well as the outcome of the joint learning process during the interview. This body of newly retrieved data and knowledge is reported in the study's empirical findings and presented in the final version of the model. In this study, the conceptual multi-level readiness framework was discussed during each interview and modified according to each participant's suggestions, understanding, and experience in the field. Such modifications were compared in a further analysis, which considered the most recurring suggestions. In addition, the interview data were analyzed using a thematic analysis (Braun & Clarke, 2006), a systematic method for discovering themes in complex data sets by coding and categorizing common phrases and themes expressed by interviewees. The analysis identified two core themes: strategies and activities for the transition to a circular economy and perceptions about the circular economy transition. The outcomes of such a process for data analysis are presented in the empirical findings section of this paper.

Theoretical frameworkCircular economy implementationThe concept of a circular economy has garnered significant attention from policymakers and institutions (Brennan et al., 2015; Ellen MacArthur Foundation, 2013, European Commission, 2020). The early-stage development of a circular economy can be traced back to the work of Stahel and Reday-Mulvey (1981), who conceptualized the vision of an economy in loops and its impact on job creation, economic competitiveness, resource savings, and waste prevention (Stahel & Reday-Mulvey, 1981). Geissdoerfer (2017) conducted a bibliometric analysis of developments in the growing circular economy field, showing that it had attracted greatly increased interest in a short timeframe, which was reflected in a steady, exponential growth in publications (Geissdoerfer et al., 2017). Non-academic parties have led the way in driving progress on work on the circular economy (Schut et al., 2015). Many stakeholders have begun to familiarize themselves with the circular economy concept, leading to a wide set of related definitions and conceptions (Lieder & Rashid, 2016) that are often unclear and diverse (Corona et al., 2019) due to a lack of sector-specific understanding (van Keulen & Kirchherr, 2021). Following Kirchherr et al. (2017) definition, one of the most important features of a circular economy falls within the concept of micro, meso, and macro levels. Distinguishing such levels is imperative for understanding the circular economy (e.g., van Keulen & Kirchherr, 2021; Chirumalla et al., 2022). Initiating a transition toward circularity requires a systemic shift rather than an incremental twisting of current practices (Chirumalla et al., 2022; European Environment Agency, 2021; Frishammar & Parida, 2021; Kirchherr et al., 2017; Superti et al., 2021). Employing the concept of micro, meso, and macro levels can help understand the possible levels of depth in different interventions or key focus areas. This way of approaching the concept of circularity was of paramount importance in developing this study.

The traditional and linear approach to production and consumption currently implemented by most manufacturers is based on processing virgin raw materials in products with a planned lifespan and later discarded by consumers at the end of life. Such an approach speeds up production and consumption rates, leaving little to no space for different practices, such as recycling, repairing, product–service systems, and dematerialization (Ellen MacArthur Foundation, 2013). Therefore, in the linear model, the productivity of our natural ecosystems pays the highest price for the production of goods, and the pressure put on these ecosystems negatively affects water, air, and soil. The shift from a linear to a circular model is deemed mandatory to sustain growth despite Earth's limited resources (Planing, 2018) and the growing demand for resources. Unlike the linear model, a circular business model is “restorative by intention,” meaning that it is based on energy recovery, restoration, recycling and refurbishing, reuse and maintenance, and the general minimization of waste (Ellen MacArthur Foundation, 2013).

Making the shift from a linear to a circular economy is a rather complex and costly operation that can present various grounds for uncertainty and risk (Bjornbet et al., 2021; Frishammar & Parida, 2019; Kirchherr et al., 2018; Linder & Williander, 2017; van Keulen & Kirchherr, 2021; Werning & Spinler, 2020). Among these, the need for specialized technological expertise and foreseeable operational risks (Linder & Williander, 2017); coherence in governmental policies, “silo thinking” of industries, the standardization of circular design (van Keulen & Kirchherr, 2021), and the tensions between the initiating company and other actors in the value chain (Frishammar & Parida, 2019) are critical. A study in the EU by Kirchherr et al. (2018) found that cultural barriers, particularly a lack of consumer interest and awareness and a hesitant company culture, are key barriers confronting businesses and policymakers. The difficulty in overcoming the traditional measurement of sales-based performance and the willingness to take on long-term strategies are two of the most relevant barriers to adopting a circular business model (Werning & Spinler, 2020). Finally, Bjornbet et al. (2021) reviewed the case study literature on the circular economy in manufacturing. They found 14 articles that explicitly discussed barriers to circular economy implementation, such as financial and economic awareness, available systems and knowledge needs, appropriate partners and stakeholder engagement, and organization- and technical-related barriers. Therefore, the creation of a solid approach to support manufacturers in their transition is needed, and the aid of specific tools is of paramount importance. Several tools can support companies in implementing new strategies in the field of change management. Among these, maturity models and readiness level models (e.g., Ferreira et al., 2019; Parida et al., 2019; Singh et al., 2018; Sacco et al., 2021; Thorley et al., 2022) are widely used, especially in large manufacturing companies, to facilitate the level of progress in different stages of the transition.

However, the proposed maturity and readiness models have been examined for various purposes. For instance, Singh et al. (2018) evaluated circularity by integrating the theory of planned behavior with environmental commitment and green economic incentives. Similarly, Sacco et al. (2021) introduced overall dimensions to gauge circularity and maturity at the firm level, albeit in separate assessments. However, their approach lacked a detailed activities list that considered progression across cross-functional business areas. Moreover, Parida et al. (2019) proposed a circular readiness model primarily focusing on ecosystem transformation. Nevertheless, their model lacked clarity regarding the progression of readiness across cross-functional business areas at the firm level.

Multi-level readiness framework for transitioning toward a circular economyReadiness levels describe the firm's state of preparedness and assessment with regard to large-scale change or transformation under specific key dimensions (e.g., Agudo et al., 2022; Parida et al., 2019; Thorley et al., 2022). The technology readiness level (TRL), one of the most used models, was first developed by NASA and then adopted in other fields (Mankins, 1995). Specifically, highly engineering-based organizations commonly use and accept readiness level models. Readiness models provide an in-depth understanding of the progress of complexity and development of a certain aspect, employing a holistic approach. They help address a number of challenges in the implementation and transition to a circular economy using systematic assessments (Pigosso & McAloone, 2021).

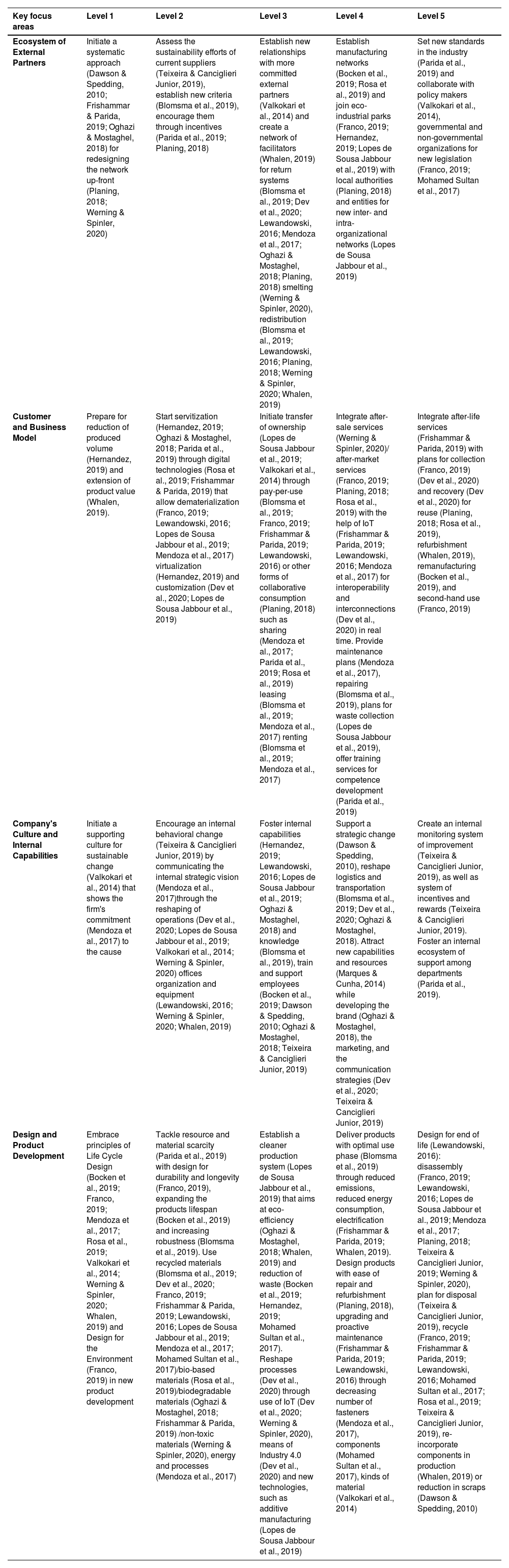

A multi-level readiness framework for transitioning to a circular economy was developed based on the research process adopted, particularly the systematic literature review (as explained in the research methodology section). Based on the literature analysis, four key focus areas and five levels of progression were identified, which became part of the proposed framework. A progression of levels from 1 to 5 was adopted, ranging from a general understanding of concepts in level 1 to a growing operationalization across further levels up to full implementation in level 5. In addition, the four key focus areas include 1) the ecosystem of external partners, 2) the customer and business model, 3) the company's culture and internal capabilities, and 4) design and product development. The first version of the multi-level readiness framework is presented in Appendix B. The framework includes four key focus areas, and the readiness progression levels of these four areas range from 1 to 5.

The ecosystem of external partners deals with everything external to the company in terms of relationships with suppliers (Frishammar & Parida, 2019; Valkokari et al., 2014), facilitators (Planing, 2018; Pigosso & McAloone, 2021; Whalen, 2019), actors in the same geographical context (Mohamed Sultan et al., 2017), and governmental and non-governmental entities and policymakers (Franco, 2019; Hernandez, 2019; Rosa et al., 2019).

- •

The first level of readiness for this area illustrates the need to use a systematic approach to redesign the network of actors external to the company in order to align the efforts of all actors of the value chain involved in circularity (Bocken et al., 2019; Frishammar & Parida, 2019; Hernandez, 2019; Pigosso & McAloone, 2021). This must be done upfront (Werning & Spinler, 2020).

- •

The second level deals with assessing the environmental commitment of existing partners and suppliers (Teixeira & Canciglieri Junior, 2019). It encourages them through incentives to meet new and more sustainable criteria if their current ones do not meet company expectations (Parida et al., 2019; Planing, 2018).

- •

Subsequently, the importance of new relationships with more committed partners (Dev et al., 2020) actively facilitating circular practices is underscored. Such relationships can include facilitators (Planing, 2018), redistributors, and retail partners (Whalen, 2019) across existing value chains (Franco, 2019).

- •

The fourth level includes different horizontal relationships (Valkokari et al., 2014) of non-competitor partners who belong to different industries and sectors (Marques & Cunha, 2014), with the possibility of joining eco-industrial parks (Franco, 2019; Lopes de Sousa Jabbour et al., 2019; Rosa et al., 2019).

- •

Ultimately, collaborations with governmental and non-governmental organizations (Dawson & Spedding, 2010) are presented to create stronger and more precise legislation on circular economy goals and requirements with which competitors in the market and other industries will need to comply (Pigosso & McAloone, 2021).

Continuing on, the customer and business model area acts as a bridge between the outside (i.e., ecosystem) and inside (i.e., firm) of the company. The major standpoints in this area include challenging the traditional linear model (Hernandez, 2019; Oghazi & Mostaghel, 2018), the transfer of ownership (Blomsma et al., 2019; Mendoza et al., 2017), and the implementation of innovative services (Bocken et al., 2019; Frishammar & Parida, 2019), all of which can help to shape different value-creation options for the company (Lopes de Sousa Jabbour et al., 2019; Pigosso & McAloone, 2021).

- •

The first level of readiness for the customer and business model area includes the need for the company to settle for reduced produced volume units (Hernandez, 2019). When extending the product value, the revenue flow does not necessarily rely on products that can be sold but rather on the services that can be offered.

- •

The second level focuses on servitization through product–service systems (Blomsma et al., 2019; Bocken et al., 2019; Franco, 2019; Frishammar & Parida, 2019; Hernandez, 2019; Marques & Cunha, 2014; Mendoza et al., 2017; Oghazi & Mostaghel, 2018; Pigosso & McAloone, 2021; Rosa et al., 2019; Valkokari et al., 2014; Werning & Spinler, 2020; Whalen, 2019). Servitization is indeed made possible by digital technologies that allow dematerialization (Franco, 2019; Lewandowski, 2016; Lopes de Sousa Jabbour et al., 2019; Rosa et al., 2019), virtualization (Hernandez, 2019), customization of customer needs (Bocken et al., 2019; Dev et al., 2020), and product life extension (Pigosso & McAloone, 2021).

- •

The third level describes how different business models based on access-over-ownership (Blomsma et al., 2019) can be implemented in sharing, leasing, or renting (Franco, 2019; Hernandez, 2019; Marques & Cunha, 2014; Mendoza et al., 2017; Oghazi & Mostaghel, 2018; Parida et al., 2019; Planing, 2018; Rosa et al., 2019; Werning & Spinler, 2020; Whalen, 2019).

- •

The fourth level concerns profitable services contemplated in the after-market phase, such as maintenance plans (Blomsma et al., 2019; Dev et al., 2020; Franco, 2019; Frishammar & Parida, 2019; Marques & Cunha, 2014; Mendoza et al., 2017; Oghazi & Mostaghel, 2018; Planing, 2018; Rosa et al., 2019; Valkokari et al., 2014; Werning & Spinler, 2020), repairs (Oghazi & Mostaghel, 2018; Planing, 2018; Pigosso & McAloone, 2021), plans for waste collection (Werning & Spinler, 2020), and training services for competence development (Parida et al., 2019). Once again, the Internet of things (IoT) is the main enabler of the services described, thanks to the possibility of interoperability and real-time connection it provides (Dev et al., 2020; Oghazi & Mostaghel, 2018; Rosa et al., 2019; Werning & Spinler, 2020).

- •

Finally, the fifth level focuses on feasible services for the end-of-life phase: plans for collection (Marques & Cunha, 2014; Werning & Spinler, 2020), recovery (Oghazi & Mostaghel, 2018; Rosa et al., 2019; Werning & Spinler, 2020; Pigosso & McAloone, 2021), refurbishment and remanufacturing (Blomsma et al., 2019; Frishammar & Parida, 2019; Mendoza et al., 2017; Planing, 2018; Whalen, 2019), and recirculation of second-hand products (Blomsma et al., 2019; Franco, 2019; Oghazi & Mostaghel, 2018; Rosa et al., 2019; Valkokari et al., 2014; Werning & Spinler, 2020; Whalen, 2019).

Going further, the company's culture and internal capabilities area deals with the people and the culture of the organization (Dawson & Spedding, 2010; Werning & Spinler, 2020) in connection with existing and new capabilities (Pigosso & McAloone, 2021), the fostering of new circular knowledge (Bocken et al., 2019; Frishammar & Parida, 2019; Thorley et al., 2022, and the supportive culture for change and innovation across all departments (Rosa et al., 2019; Thorley et al., 2022).

- •

The first level concerns a supportive culture for sustainable change (Valkokari et al., 2014) inspired by the company's commitment to the circular economy (Mendoza et al., 2017).

- •

Furthermore, the behavioral changes connected to such commitment (Teixeira & Canciglieri Junior, 2019) can be seen in the reshaping of operations management (Dev et al., 2020; Valkokari et al., 2014), transportation and logistics (Dawson & Spedding, 2010), and office equipment and organization (Lewandowski, 2016; Whalen, 2019). It is a matter of cultural adaptation (Lewandowski, 2016) and strategic reorganization of the company's vision in a more circular direction (Mendoza et al., 2017).

- •

The third level describes how the company should support its employees in better understanding, knowing, and managing the circular economy while fostering their capabilities (Blomsma et al., 2019; Fernandez & Fernandez, 2009; Oghazi & Mostaghel, 2018; Pigosso & McAloone, 2021; Teixeira & Canciglieri Junior, 2019), with a focus on the role of entrepreneurial (Bocken et al., 2019) and leadership support (Parida et al., 2019; Thorley et al., 2022).

- •

The fourth level promotes enterprise modelling (Dawson & Spedding, 2010) by attracting new intellectual resources with extensive capabilities and knowledge within a circular economy (Marques & Cunha, 2014; Pigosso & McAloone, 2021).

- •

Ultimately, a monitoring system of improvements and incentives is presented, as well as creating an internal system of support and cooperation involving different teams (Teixeira & Canciglieri Junior, 2019).

Finally, the design and product development area deals with a more specific operational aspect for R&D, engineering, industrial design, and production processes (Dev et al., 2020; Teixeira & Canciglieri Junior, 2019). It takes into account life-cycle assessment (Valkokari et al., 2014), which allows loops to be closed (Franco, 2019) because it is based on different and gradually more complex approaches to product development, from general design for the environment to design for disassembly and recycling (Dev et al., 2020; Mohamed Sultan et al., 2017).

- •

The first level of readiness for this area focuses on life-cycle design (Bocken et al., 2019; Franco, 2019; Valkokari et al., 2014; Werning & Spinler, 2020; Whalen, 2019) for new product development.

- •

The second level introduces the concepts of durability (Bocken et al., 2019; Franco, 2019; Mendoza et al., 2017; Oghazi & Mostaghel, 2018; Teixeira & Canciglieri Junior, 2019; Werning & Spinler, 2020; Whalen, 2019), longevity (Blomsma et al., 2019), and robustness (Teixeira & Canciglieri Junior, 2019; Valkokari et al., 2014; Werning & Spinler, 2020). The materials, energy sources, and production processes selected should be recycled (Mohamed Sultan et al., 2017; Oghazi & Mostaghel, 2018), bio-based (Mendoza et al., 2017; Rosa et al., 2019), biodegradable (Mendoza et al., 2017; Oghazi & Mostaghel, 2018; Pigosso & McAloone, 2021), and non-toxic (Werning & Spinler, 2020).

- •

The third level describes a cleaner production system aimed at eco-efficiency (Valkokari et al., 2014) and waste reduction. Implementing innovative technologies, such as additive manufacturing (Dev et al., 2020; Rosa et al., 2019) can speed up the adoption of such activities, especially in the creation of prototypes and small components.

- •

The fourth level focuses on products' use phase, including lowering energy consumption and pollutant emissions (Blomsma et al., 2019; Oghazi & Mostaghel, 2018; Valkokari et al., 2014). Product design guidelines must focus on ease of repair (Franco, 2019; Mohamed Sultan et al., 2017; Planing, 2018) and a decreased number of fasteners and components.

- •

Finally, the fifth level focuses on product end-of-life, considered from the perspective of remanufacturing (Dev et al., 2020; Pigosso & McAloone, 2021). Thus, the linear “cradle-to-grave” approach is entirely rejected in favor of adopting the “cradle-to-cradle approach”, with the re-incorporation of different components into the production processes (Blomsma et al., 2019).

The empirical results from the semi-structured interviews are presented as follows. First, the informants validate the conceptual multi-level readiness model for transitioning toward a circular economy, including four key focus areas. Second, strategies and key activities are described for the transition to a circular economy.

Circular transition requires a multi-level readiness approachAccording to many informants, large manufacturing companies are likely to operate within a rather linear mindset due to the major influence of waterfall engineering processes and methodologies in their day-to-day work. Hence, tools such as TRLs are adopted mainly thanks to their well-defined structure and ability to frame and partition a problem in a logical chain of sub-components. For this reason, during the validation, all participating informants acknowledged the significant importance of the multi-level readiness framework, considering it a valuable tool to help the transition toward circularity. Moreover, the concept of a multi-level readiness framework, which considers four different key focus areas, enables the framing of a complex and broad concept such as circularity in a holistic and cross-functional way.

According to the sustainability and public affairs vice-president, the suggested framework for transitioning toward a circular economy is “richly descriptive. It makes it easy to assess the company's current status in the transition, and it helps to calibrate the understanding of where we are right now, what gap we need to fill, and how we can go further”. Initially, a few informants pointed out that the proposed framework requires some effort from the reader to become familiar with the rather rich content that explores the complexity of circularity, especially those with less familiarity with the topic of a circular economy. Yet, informants such as the manager of manufacturing technology management development and governance and the chief project manager for advanced engineering have acknowledged the explanatory and educational features of the framework.

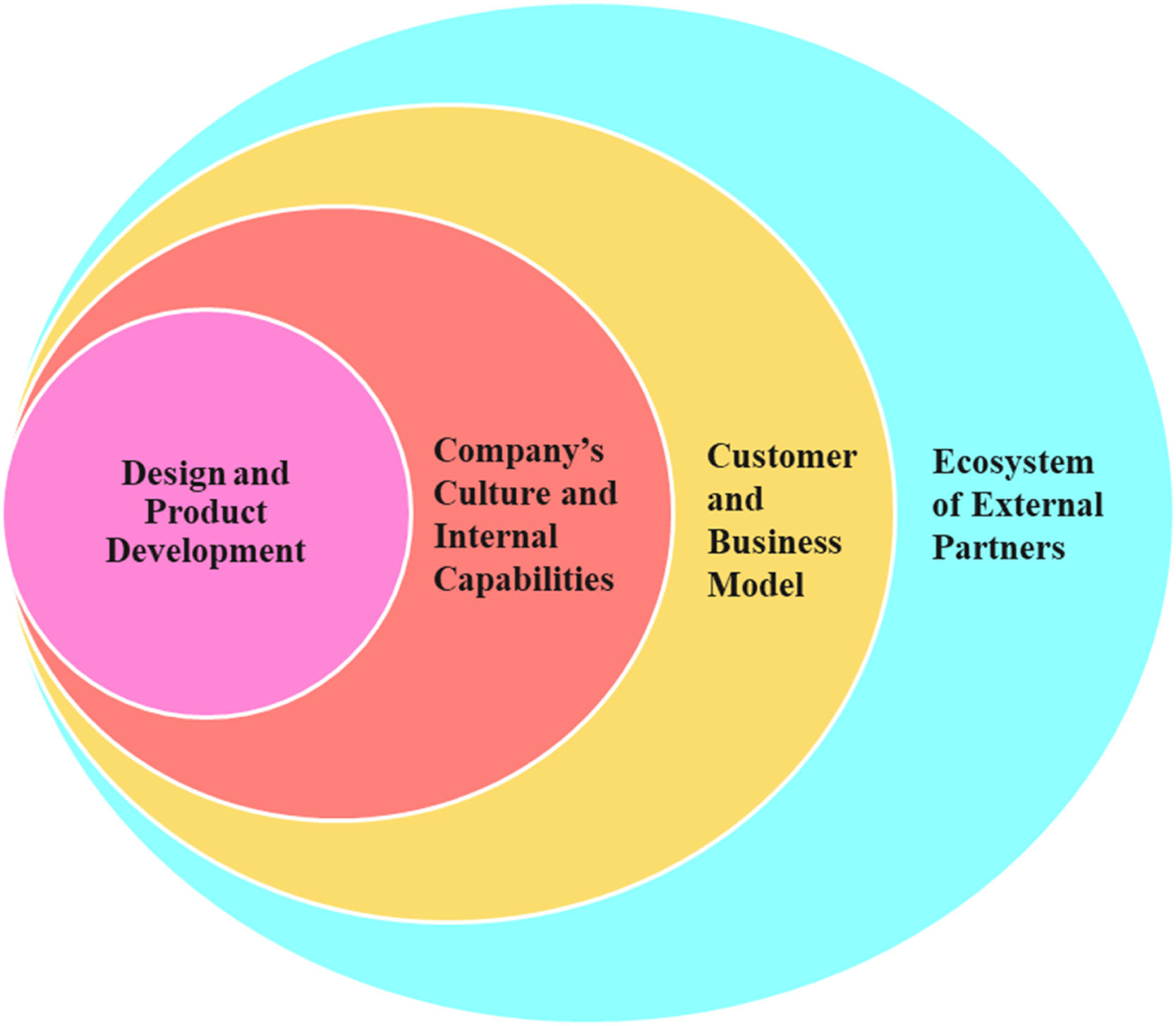

Key focus areasFig. 2 illustrates the four key focus areas and their mutual interdependence. Each key focus area in the figure represents an independent domain, yet each exhibits a spectrum of breadth, ranging from specific to broad. It is important to note that this does not imply hierarchical inclusion, where one area encompasses another. The focus areas presented in the framework were deemed comprehensive and exhaustive by all informants, who stated that no focus area should be addressed as a trigger to the other areas but rather there should be a simultaneous and gradual approach to every focus area as outlined by the technology planning manager. As stated by the chief project manager for advanced engineering, “the transition towards circular economy must be done systematically”, whereas the director of sustainability and public affairs used the term “holistic” to define the approach to the transition.

Additionally, the informants emphasized the importance of having a hands-on cross-functional framework for a circular transition. Such a framework could guide various functional areas of the company to collaborate toward the common goal of achieving circularity. This contrasts with the approach where one area is expected to initiate the change and pull along every other area.

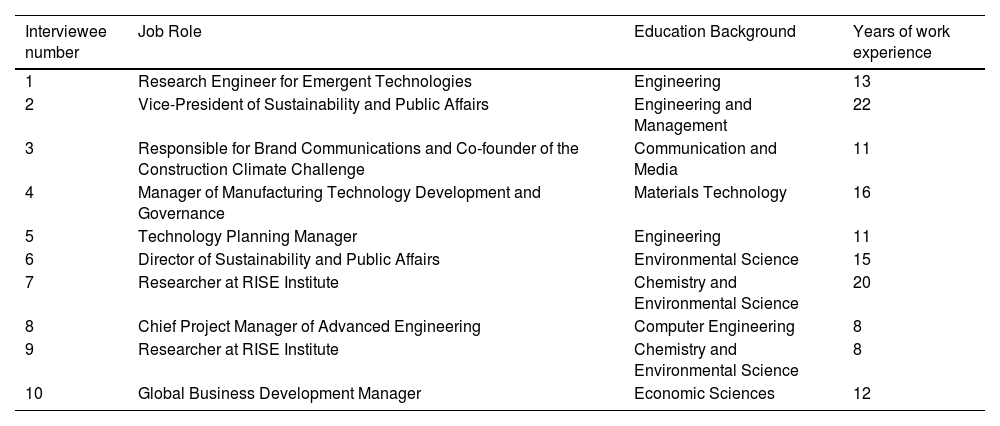

The following sub-sections analyze each focus area with regard to the different levels and suggested modifications by interviewed informants. Table 2 shows the finalized multi-level readiness model that includes informants’ perspectives.

The proposed multi-level readiness framework for the transition to the circular economy in manufacturing companies.

The definition of the ecosystem of external partners area was generally well received by all informants. It was deemed explanatory of the complex structure of entities connected with a company from both vertical (supply chain) and horizontal (non-economic) perspectives.

The manager of manufacturing technology management highlighted the need to visualize the meaning of making the transition toward circularity, with a focus on the practical implications of reframing the relations with partners before actually initiating the change: “Initiate a systematic approach for redesigning the network of suppliers and collaborators up-front by visualizing what it will mean to make the transition”. On the following level, the research engineer added the need to share common working ethics and values among business partners for emergent technologies: “Assess the sustainability efforts of current suppliers, establish new criteria, encourage them through incentives, have the same working ethics and values”. On the third level, the description of activities and strategies did not change from the previous version, showing the total agreement of informants in its drafting, thereby resulting in: “Establishing new relationships with more committed external partners and creating a network of facilitators for return system, smelting, redistribution”. On the fourth level, the technology planning manager specified that “joining eco-industrial parks could be one of the many ways to successfully cooperate with different actors that belong to the same geographical areas”. Therefore, the need to establish new manufacturing networks (i.e., eco-industrial parks with local authorities and entities) is highlighted with a specific focus on effort and knowledge-sharing among the different actors of the value chain. Finally, the fifth level of the ecosystem of external partners area includes the standpoint of the informant responsible for brand communications and co-founder of the construction climate challenge on companies’ imperative awareness of “their impacts on the surroundings where different production plants are located”. This is naturally connected to the urge to establish new environmental standards in the industry and possibly trigger proactive changes in legislation.

Key focus area 2: customer and business modelRegarding the customer and business model area, informants showed a generally positive acceptance of the overall content regarding concepts and logical consistency of the levels while adding their perspective from an industrial standpoint. In terms of this area's first level, the research engineer for emergent technologies highlighted the possible issues that can be encountered when negotiating new circular business models with customers – specifically, the cultural barriers that can emerge when the retention of product ownership is involved. Hence, the main takeaway on this level is “negotiate new business model with customers, prepare for reduced produced volume and extension of product value”.

The definition of the second level remained unchanged compared to the previous version: “Start servitization: integration with digital technologies that allow dematerialization, virtualization, and customization”. Likewise, the third level remained the same: “Initiate transfer of ownership through pay-per-use or forms of collaborative consumption such as sharing, leasing, renting”. However, the fourth level includes the perspective of the chief project manager for advanced engineering on the need to design products that are perfectly integrated with the technology and their use phase. This informant stated, "technology cannot do everything, and the engineering side must always meet high-quality standards.” Hence, digital technologies are pivotal for interoperability and interconnections in real time. However, their primary purpose is to secure an efficient use of products.

Finally, the last level in this area places particular emphasis on the financial aspects connected to the transition toward a circular economy. Several informants (research engineer, co-founder of Climate Challenge, researcher, technology planning manager, and global business development manager) commented that this topic requires the utmost attention, thereby underscoring the need to find a balance between sustainability efforts and cost efficiency.

Key focus area 3: company's culture and internal capabilitiesAll informants acknowledged the importance of including the company's culture and internal capabilities in the transition toward circularity while highlighting how barriers can remain silent yet still challenge the company's ability to change.

In the first level of this area, the research engineer for emergent technologies introduced the concept of “transparency” in connection with the firm's decision to transition toward circularity. This concept is then developed in the second level thanks to the input from the co-founder of climate challenge and from the chief project manager for advanced engineering. Both confirmed that the company must ensure that its employees understand the reasoning behind the transition and have a solid knowledge base for the company's own definition of a circular economy that takes into account the company's true needs and capabilities. The following level presents the viewpoint of one of the researchers who stated that “companies can boost the competences of their employees with workshops that have specific aims, such as understanding new challenges, risks, expected consequences and possible implications” in connection with the transition toward circularity. Moving forward, the fourth level remained unchanged, while the fifth level presented the concept of a success story as highlighted by the co-founder of climate challenge, the manager of manufacturing technology management, and the chief project manager for advanced engineering. In particular, according to the co-founder of climate challenge, a success story is something that “can increase everyone's motivation and commitment around [a] topic”. Thus, sharing success stories across the organization on achievements in the transition toward circularity is important in order to trigger long-term change.

Key focus area 4: design and product developmentThe overall impression of participants regarding the design and product development area was largely positive. The discourse on this area was mostly centered on the pivotal role of new technologies and engineering and design practices in the quest for circularity.

On the first level of this area, one of the researchers highlighted the role of technical excellence. In contrast, the manager of manufacturing technology management pinpointed the concept of creativity as an enabler for the principles of lifecycle design and environmental design. Although the second level did not change consistently, the third one included the standpoint of the research engineer for emergent technologies, who mentioned the need to understand three aspects of the trade-off curve: financial viability, health safety, and environmentally friendly. The fourth level highlights the strategy of proactive maintenance, as expressed by the chief project manager for advanced engineering, and the implementation of sensors to predict failures thanks to the contribution of one of the researchers. Ultimately, the original definition of level 5 was agreed by informants, so no changes were made.

Strategies for transition to a circular economyIn addition to the four key focus areas and five levels of progression, the empirical data analysis revealed four strategies for the successful transition to a circular economy: 1) changing the mindset, 2) understanding the concept and establishing one's definition, 3) high-level planning and evaluation of scenarios, and 4) ensuring financial viability and environmental preservation.

Changing the mindsetAccording to the empirical analysis, many informants stressed that one of the most important activities to implement when dealing with the transition toward a circular economy is for the organization to make a disruptive shift from a linear-traditional to a circular mindset. Such a shift has a far-reaching impact on production (according to informants 1 and 8), supply chain management (according to informants 5 and 6), logistics (according to informant 10), and communication (according to informant 3).

The research engineer for emergent technologies explained that “it is necessary to challenge the conventional way of how we design things, because usually, the conventional approach is not necessarily the most correct one”, meaning that it is rather challenging to make changes in established practices and protocols and that “more efforts can be done in other directions thanks to the implementation of innovative technologies.” This concept sheds light on the connection between innovation and circularity. Building on this, the chief project manager for advanced engineering highlighted how “not only the technical aspects of machines must be in place, but also an alignment with the latest research and state-of-the-art knowledge provided by academic partners and collaborations through research projects.” Thus, the collaboration between industry and academic research is seen as a pivotal enabler to lay the foundations of a successful transition toward circularity. Furthermore, the manager of manufacturing technology management focused on the need to “think outside of the box” and “seek for new concepts while incorporating creativity in the approach to change”, including the concept of creativity and shifting the mindset. Finally, one of the researchers highlighted how “establishing cross-functional groups of experts in the field can set the right directions for every department and project,” meaning that experience from different backgrounds and knowledge areas can synergistically lead to effective change.

Understanding the concept and establishing one's definitionA pivotal aspect facilitating the transition toward circularity is connected to the company's internal understanding of the circular economy concept. The transition must be driven from the inside through a “well-established and shared knowledge base regarding the definition of circularity for the company, with regard to its needs and capabilities,” as described by the global business development manager. Thus, each company should be able to frame the concept of circularity from its particular standpoint, relying on capabilities already in place and on its tangible needs rather than depending solely on mainstream practices. In this connection, the co-founder of Climate Challenge suggested the possibility of “breaking the topic down, creating a tailored definition of circular economy, and spreading it across the company to build a success story that can increase everyone's motivation and commitment around it”. This point of view elaborates on creating a company's definition of circularity based on a thorough understanding of the concept. Moreover, regarding the theme of internal motivation and commitment to drive the transition, it explains the position of one of the researchers, who asserted that companies should “mainly rely on their intrinsic motivation to make the transition towards circularity since the external factors such as legislation are currently not strong enough to drive the change.” Such a severe but disenchanted standpoint sheds light on the fact that current legislation cannot yet drive industries toward effective sustainable practices.

High-level planning and evaluation of scenariosAn important strategy to facilitate the transition toward circularity is “foreseeing possible outcomes of the different activities that can be implemented, also in connection to risk management procedures,” as stated by the manager of manufacturing technology management. This high-level point of view focuses on the power of imagining different scenarios, evaluating possible risks, and planning response strategies. Here, the vice-president of sustainability and public affairs gave a perspective on in-depth, low-level planning: “Things should be planned ahead and with as many in-depth details as possible.” In this connection, the possibility of testing and evaluating different circular scenarios with the aid of software for model-based testing is highlighted. The research engineer for emergent technologies stated that “there are specialized calculation software that can predict how different products and systems of products function under certain circumstances, thanks to virtual representations of such circumstances. In-depth assessments and evaluations can be done, and the outcome of such processes can lead to optimizing product data management and allow a well-planned and distributed work for different departments of the company.”

Ensuring financial viability and environmental preservationThe activity of “establishing new, tangible and measurable goals connected to a circular economy” is deemed necessary, according to one of the researchers, in order to ensure the company's success in making the transition toward circularity. This means that conventional ways of measuring a company's success (such as increased sales or production rates) might not apply to circular practices. Yet, as the global business development manager stated, “finding a balance between financial KPIs (key performance indicators) and environmental KPIs is an activity that requires further attention and efforts from the company.” This standpoint highlights the fact that strategic practices that aim for a circular shift should never jeopardize the company's financial stability and vice versa. In this connection, the research engineer for emergent technologies expressed a rational point of view on the high costs of manpower in maintenance and repair, stating that “sometimes it can be far more expensive to repair a component than to replace it with a new one” and that “the current financial structure can counteract the transition and leave us in the traditional way of doing things.” This means a truly circular strategy must contemplate appropriate adjustments to the business model and financial operations. Here, the technology planning manager stated, "we need to aim at a win–win solution for the economy and for the environment.”

DiscussionPerceptions of a case company on the circular economy transitionExisting knowledge connected to environmental sustainability can be, in part, transposed to that of a circular economy (Scott, 2015). Manufactured products with high quality and safety standards are associated with a long lifespan and the possibility of refurbished parts (Frishammar & Parida, 2019). Hence, for a manufacturing company already committed to such features in its products and mindset, the shift from sustainable to circular practices can be seen as a feasible perspective for the future.

Nevertheless, it is also clear that, despite the ever-growing literature on the circular economy (Kirchherr et al., 2017), this concept still needs to be further explored, and its definition must be decoded for each specific field or industry. Indeed, there are numerous approaches to consider, given the myriad possibilities unleashed by servitization business models, innovative production processes, and advancements in digital technologies. New tools and business models allow our societies to see promising alternatives to traditional linear models. The mindset of actors involved in the ecosystem must shift accordingly to allow circularity to take over and grow exponentially. This will create a win–win–win situation where environment and society are considered key stakeholders in addition to the firm and its ecosystem (Chirumalla et al., 2022). By doing so, it will finally be possible to have a future in which product use can be maximized to the point where profits do not solely depend on buying and selling tangible assets.

Foreseeing possible barriers to a successful transition toward circularity is paramount. The identification of barriers and their impact and the effort required to overcome them are of pivotal importance (Bjornbet et al., 2021; Werning & Spinler, 2020). Among the many barriers, the financial performance and sanity of any strategic decision must always be taken into serious consideration (Bjornbet et al., 2021; Werning & Spinler, 2020). Indeed, the importance of considering the financial aspect when talking about the circular transition was highlighted by many informants (i.e., 1, 3, 5, 7, and 10). A careful and precise feasibility analysis, cost prediction models, and return projections must always support every strategic decision that aims to embrace circular practices (Dev et al., 2020; Oghazi & Mostaghel, 2018).

A financial viability plan is not the only driver of a successful transition. In fact, having a holistic understanding of the circular transition in terms of areas of intervention, actions to perform, and strategies to put in place is pivotal when outlining a plan for shifting from linear to circular practices and foreseeing possible barriers. The importance of having a holistic approach to circularity was supported not only by the informants of this study but also by the previous literature (Chirumalla et al., 2022; Dawson & Spedding, 2010; Geissdoerfer et al., 2017; Lozano et al., 2021; Marques & Cunha, 2014; Mendoza et al., 2017; Mangers et al., 2021; Sgroi et al., 2018).

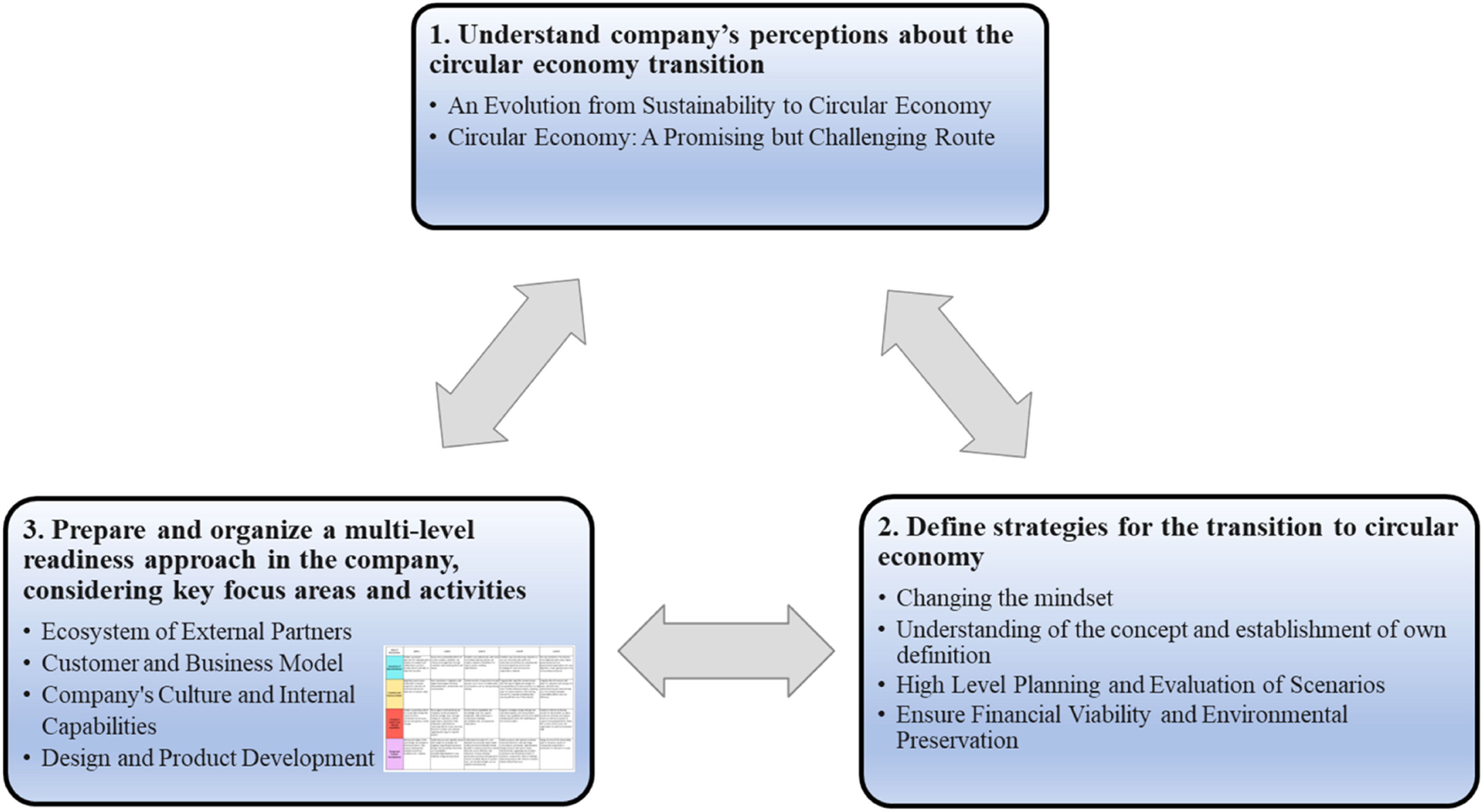

Based on this detailed theoretical and empirical analysis, our study proposes a transition guiding path for the circular economy in manufacturing companies in three iterative steps, as shown in Fig. 3:

1) Understand the company's perceptions about the circular transition

2) Define strategies for the transition to a circular economy

3) Prepare and organize a multi-level readiness approach in the company, considering key focus areas and associated activities for each area.

Theoretical and practical implicationsShifting from a linear to a circular economy is a challenging decision for large manufacturing companies due to the difficulties initiating changes in well-established protocols and coordinating and communicating such changes throughout a complex structure. Moreover, the definition of a circular economy itself is challenging to manage due to the abundance of definitions and approaches. Consequently, defining the steps to take during the transition is challenging. Cross-functional framing and a systematic approach (e.g., Bjornbet et al., 2021; Chirumalla et al., 2022; Geissdoerfer et al., 2017; Lozano et al., 2021; Mangers et al., 2021; Mendoza et al., 2017; Sgroi et al., 2018) to understanding a circular economy are pivotal factors in successfully performing the transition. Hence, this study provides a comprehensive approach to improve this understanding. Thus, it extends the works of Teixeira and Canciglieri Junior (2019) on the need to introduce strategic planning for corporate sustainability by elaborating on the cross-functional dimension stated in the previous literature (Berchicci & Bodewes, 2005).

The need for practical tools to facilitate the transition from the linear to the circular economy can be seen in the many tools proposed in the theory (Bocken et al., 2019; Chirumalla et al., 2022; Dawson & Spedding, 2010; Frishammar & Parida, 2019; Mohamed Sultan et al., 2017; Mendoza et al., 2017; Rosa et al., 2019). As highlighted in the comparative analysis, these tools have a relatively narrow perspective on the concept of circular economy, considering only a single function (Mendoza et al., 2017) or firm perspective (Lopes de Sousa Jabbour et al., 2019) rather than an ecosystem perspective (Parida et al., 2019) or both. Hence, this study contributes to the existing literature by proposing a practical framework that holistically includes many perspectives to be considered when transitioning toward a circular economy. An in-depth awareness of the readiness status of such a transition is divided into five levels, from the early developmental stage to full circularity, and each level includes a pathway to follow in terms of actions and strategies. Hence, the distinctive feature of the proposed framework is its holistic approach toward circularity that allows different silos of knowledge to be connected by interlinking the four key focus areas and related activities required for such a transition. As highlighted by the chief project manager for advanced engineering, “Sometimes there is little knowledge over what has been done in terms of circularity in other departments. This leads to a scattered overview of the direction we must take to go forward in the transition.” A visual understanding of the level of readiness reached across the company's different areas is key for improved knowledge across large organizations. Although several frameworks are available in the existing literature for firm-level assessments in manufacturing companies, these frameworks lack a cross-functional approach and an assessment of readiness progression across multiple focus areas. Our framework represents a complementary and unique approach compared to existing models, tools, and frameworks. This need emerges in particular from large manufacturing companies in the heavy-duty vehicle industry, which provides a contextual understanding of this industrial sector.

Our study advances the current understanding and application of circular economy frameworks in manufacturing by offering a holistic perspective, cross-functional integration, readiness levels, a visual assessment tool, and practical application. It addresses the limitations of existing models by providing a detailed roadmap and tools that support the strategic planning and operational execution of circular economy initiatives. This permits a more interconnected understanding of the necessary steps and strategies required for large manufacturing companies to navigate the complex transition from linear to circular systems. In particular, our study advances the current understanding as follows. First, a holistic perspective stresses the need for a multi-faceted approach that ensures all relevant aspects of the transition are accounted for, offering a more robust and sustainable pathway to circularity. Second, cross-functional integration highlights the need to bridge gaps between different departments and define a cohesive and coordinated strategy for circular economy initiatives. This is particularly critical in large manufacturing settings where silos can impede comprehensive implementation. Third, the framework includes five distinct readiness levels, which highlight the significance of defining granular details in terms of specific actions and strategies at each stage of the transition from initial to full circularity. This structured progression helps companies systematically enhance their circular economy practices over time, tailored to the unique needs and maturity levels of different departments. Fourth, the visual assessment tool helps companies gauge their current readiness status and identify areas for improvement. By visually tracking and communicating their progress across different departments, this tool supports project and portfolio managers in making informed decisions and prioritizing initiatives that drive the circular economy transition forward. Finally, our study shows the empirical validation of the framework using a case study in the heavy-duty vehicle industry, demonstrating how companies can assess and enhance their circular economy practices. This real-world application underscores the framework's practicality and effectiveness, providing a valuable reference for other manufacturing companies who seek to embark on a similar transition.

The transition toward a circular economy must be seen from a change management perspective. Earlier studies have highlighted this aspect, but they lack an overall systematic picture and focus instead on specific areas of knowledge, such as operations management (Lopes de Sousa Jabbour et al., 2019), supply chain management (Dev et al., 2020), and recyclability (Mohamed Sultan et al., 2017). Our study proposes strategies and activities from different key focus areas required for such a change. The suggested multi-level readiness framework and empirical validation provides an overview of factors that must be considered in order to unlock a traditional engineering company making the transition toward the circular economy.

It cannot be stressed enough how important it is to create a practical and tailor-made definition of the circular economy from the company's perspective. Regardless of how broad and complex the definition can be, a well-defined parameter and a set of useful information included in that parameter can support efforts to understand the concept from high-level planning to the operational level.

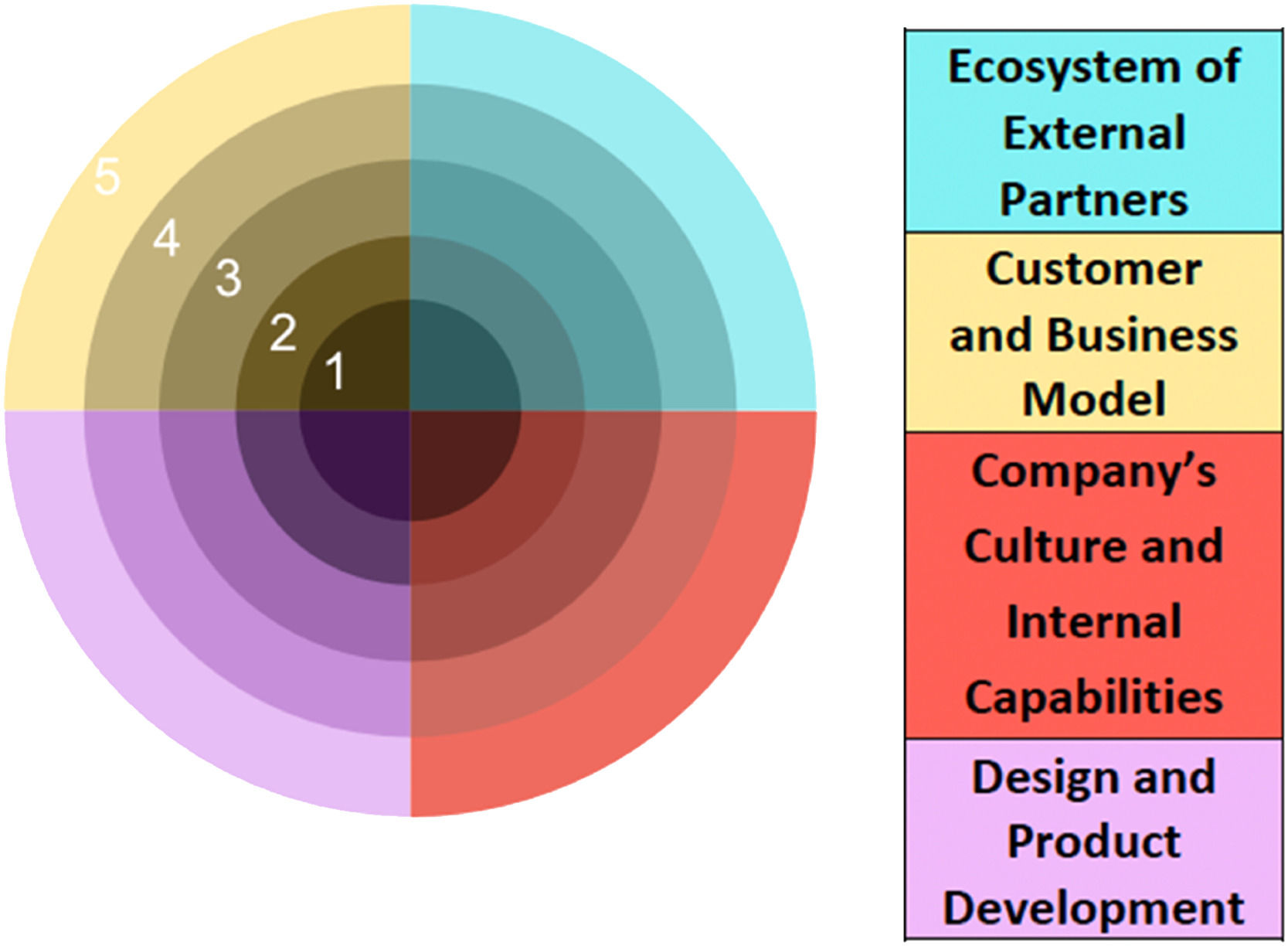

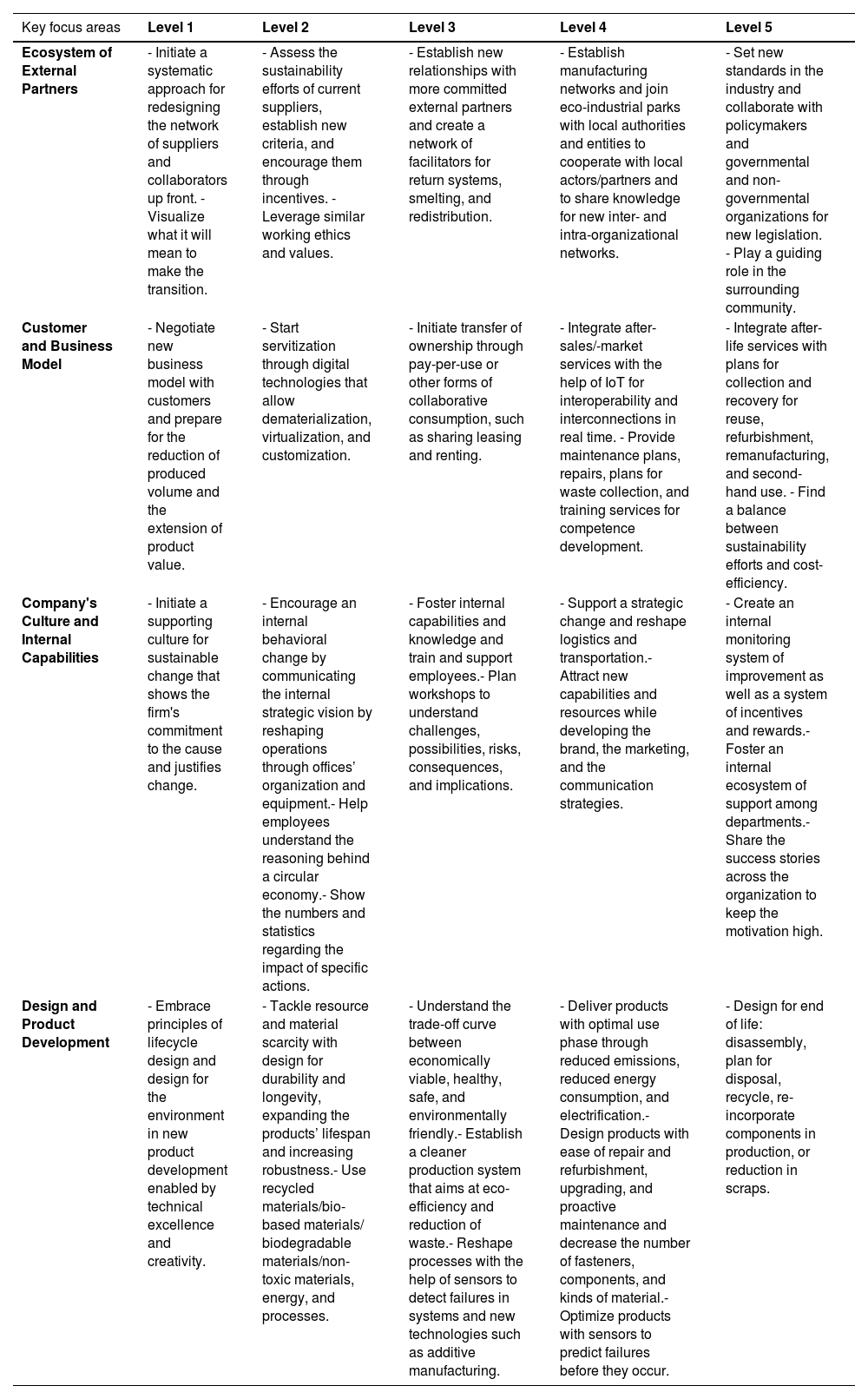

The four defined key focus areas recall and expand the concepts of micro, meso, and macro perspectives that need to be considered when dealing with circularity, as Kirchherr et al. (2017) expresses in their circular economy definition. The areas of the multi-level readiness framework are called the ecosystem of external partners, customer and business model, company's culture and internal capabilities, and design and product development. The ecosystem is a concept that includes the external world of connected partners and stakeholders in business, market, and society and sits parallel with the meso and macro levels of industrial parks, the city, the region, and the nation. The customer and business model, the company's culture and internal capabilities, and design and product development are connected to the micro level of products and companies. Additionally, Fig. 4 presents a supplementary tool that can be utilized to align with the multi-level readiness framework. The visualization showcases four key focus areas represented by concentric circles, corresponding to the five readiness levels outlined in Table 2, which are described in the multi-level readiness framework. The visuals are selected from input and ongoing assessment tools in the case company, and from consulting the maturity diagrams and levels used in the existing literature.

The visual assessment tool can be employed in conjunction with the main multi-level readiness framework to gauge readiness for transitioning toward circularity in terms of practices, strategies, and initiatives implemented by various departments. This tool proves beneficial for evaluating the current status of departments and aids project and portfolio managers, as well as department managers, in selecting strategies to enhance circular economy initiatives. For instance, organizing circular economy workshops involving participants from different departments and utilizing both the multi-level readiness framework and the visual assessment tool enables cross-functional teams to analyze and evaluate their present status and future objectives. These tools facilitate the assessment of each department's progress in implementing circular activities and strategies while laying the groundwork for subsequent steps. Fig. 4 showcases a mockup of the visual tool's utilization. Conventional engineering approaches dominate the heavy-duty vehicle industry. Hence, adopting a circular economy mindset and defining how to work across cross-functional organizations is very complex. Considering the range of products and the operational contexts of different customers poses unique challenges in this industry. It is difficult to get all cross-functional stakeholders to agree on circular initiatives and create a concrete action plan and framework for change. The proposed multi-level readiness framework in four focus areas addresses this need precisely.

Referring to Fig. 5, the tool indicates the current readiness levels of key focus areas. In the mockup provided, the "Company's Culture and Internal Capabilities" area is positioned at the highest level of readiness, indicating that the fictional department has effectively implemented a comprehensive set of circular activities and strategies. Similarly, the "Ecosystem of External Partners" area belongs to level 4, signifying an advanced readiness status, which prompts the need for strategizing to reach the subsequent and more advanced level. In contrast, the readiness level for the "Design and Product Development" area is in its initial stages, suggesting the necessity for increased attention to future strategic approaches in the respective departments. Similarly, the "Customer and Business Model" area is at level 2, requiring further attention to progress along the levels and achieve an advanced status in the transition toward a circular economy.

Finally, a transition guiding path for the circular economy in manufacturing companies is suggested, which can link all relevant strategic discussions together. It provides an overall circular transition vision for industrial companies. This simplified practical approach, considering perceptions, strategies, and multi-readiness levels, can support cross-functional organizations in the company to obtain a consensus and overall direction on the circular economy drive.

Conclusions, limitations, and future research directionsTransitioning to a circular economy is a critical challenge for many large manufacturing firms dominated by the traditional linear approach to business. Such a transition is certainly encouraged by policymakers and governmental organizations. Yet, the practical implications of such a transition are usually hard for industrial companies to understand and successfully implement. Therefore, this study has explored existing state-of-the-art knowledge employing a systematic and holistic approach to consider the key focus areas connected to the circular economy. Furthermore, the study proposes a practical framework for facilitating the process of transitioning toward circularity in a step-by-step manner that is capable of being implemented in different business domains.

The proposed multi-level readiness framework to facilitate the transition toward a circular economy aims to provide an overview of the key focus areas affected by the transition, as well as strategies and activities that should be implemented for each area. Moreover, thanks to the collaboration with an industrial partner, the framework was iterated and discussed within a practical context to ensure the reliability and validity of the research. This study has examined the complexity of transitioning toward a circular economy, focusing on the far-reaching implications affecting the decision-making processes, operations management, new product development, business model innovation, communication and marketing, supply chain management, and competence development.