The goal of this literature review is first of all to help define, characterise and contextualise the phenomena that make up Industry 4.0 (I4.0), the servitisation of manufacturing and re-shoring; and secondly to explore the strong interactions between them. We conduct a systemic literature review to identify, synthesise, assess and interpret the findings of past studies to address the research question analysed here. Industry 4.0 technologies (I4.0Ts), and particularly increased digitisation, has made for the configuration of new business models and the servitisation of the economy in the context of a new paradigm of competition. This digital servitisation is conducive to networking and enhances the role of proximity. Together with other concurrent factors (changes in relative costs, agglomeration economies, the skills and expertise in data management required by I4.0Ts) this is favouring re-shoring. Technology is always present to a greater or lesser degree as an explanatory factor in re-shoring. The increasing cognitive complexity of technical solutions is enhancing proximity constraints. More frequent, more intense contacts are needed between customers and suppliers in a production set-up that is increasingly customised.

The progressive implementation of Industry 4.0 technologies (I4.0Ts), particularly increased digitisation, and the servitisation of the economy have made for the configuration of new business models in the context of a new paradigm of competition (Kohtamäki et al., 2022; Weking et al., 2020). Digital servitisation is gradually conditioning global value chains (GVCs) (Kohtamäki et al., 2019; Vendrell-Herrero et al., 2017), and is conducive to networking as it enhances the role of proximity.

Coincidentally, the advent of I4.0Ts changes the cognitive composition of the technology solutions applied in industry and gives rise to new technology needs at production plants (Bilbao-Ubillos et al., 2023). Those needs may often entail territorial constraints in terms of access to the new knowledge now needed to engage in production revealing the advantages of clustering in the digital age when actors look for technological expertise and competences (Jankowska et al., 2021); and servitisation also raises highly specific cognitive issues with consequences especially in terms of territorial constraints. Thus, economic geographic dimension becomes more relevant and relocation decisions -among other firm's strategies- can be expected. In that context, our study thus seeks to determine the significance and scope of the technology element in explaining re-shoring processes.

Baines et al. (2009) define servitisation as “the innovation of an organisation's capabilities and processes to shift from selling products to selling integrated products-services offerings that deliver value in use”. According to Neely et al. (2011), servitisation can be summed up in five underlying shifts: 1) from a product-based world to a solution-based world; (2) from products to results; (3) from transactions to relationships; (3) from suppliers to network partners; and (5) from elements to ecosystems.

Digital servitisation describes the convergence of servitisation and digitalization (Gebauer et al., 2021). This convergence permits new ways of value creation (Porter & Heppelmann, 2015). Digital servitisation could thus be considered as the use of digital technologies for transformation processes by which a company moves from a product-centric to a service-centric business model (Kowalkowski et al., 2017).

The term re-shoring has to do with the decision to relocate manufacturing activities previously moved abroad back to the home country of the parent company (back-shoring) (Kinkel et al., 2021), to a location close to the home country with similar characteristics (nearshoring) (Pedroletti & Ciabuschi, 2023), or to another far away destination (further offshoring) (Elia & Renna, 2023). We use the term “re-shoring” here to describe in a sense equivalent to back-shoring.

There are previous papers that conduct systematic literature reviews (SLR) in the field of digital servitisation (Kohtamäki et al., 2019, 2022; Kolagar et al., 2022; Marcon et al., 2022; Martín-Peña et al., 2018; Paschou et al., 2020), but none of them covers the topic of reshoring. Similarly, previous SLRs in the field of reshoring (Fratocchi et al., 2016, 2019; Wiesmann et al., 2017; Engström et al., 2018; Eriksson et al., 2021) do not address digital servitisation. Thus, we find a marked research gap in the literature: How may I4.0Ts and digital servitisation be affecting business decisions regarding re-shoring? Cosimato & Vona (2021) is the only paper that argues that I4.0Ts applied to industrial processes and engineering applications, together with servitisation, can contribute to the implementation of sustainable reshoring strategies.

Since digital servitisation is a relatively recent, emerging stream of study, an SLR in the fields of I4.0, servitisation and reshoring by pairs is proposed, given that the link between digital servitisation and reshoring has not yet been explored by academic literature. The literature review carried out emphasises the impacts that these phenomena have on territorial dynamics within the framework of the reconfiguration of GVC and answers the following research questions:

RQ1: How has the academic literature on I4.0 and servitisation addressed the impact on territorial dynamics to date?

RQ2: How has the intersection of I4.0 and re-shoring been addressed in academic literature to date?

RQ3: How has the intersection of servitisation and re-shoring been addressed in academic literature to date?

The rest of the paper is organised as follows. Section 2 presents the main concepts sought out in the literature review. Section 3 looks at the review methodology. Section 4 sets out the main points of the pairwise comparison of concepts and summarises the findings. Finally, Section 5 discusses our findings and sets out our conclusions.

2Conceptual framework for the literature review2.1The concept of Industry 4.0According to Kagermann et al. (2013, p. 14) Industry 4.0 involves the technical integration of Cyber-Physical Systems (CPS) into manufacturing and logistics and the use of the Internet of Things (IoT) and services in industrial processes. In this sense, I4.0 is an umbrella concept for a broad range of technologies and applications to be implemented in relation to different characteristics and performance objectives (Culot et al., 2020). Frank et al. (2019a) divide I4.0Ts according to their main objectives into front-end technologies (Smart Manufacturing, Smart Products, Smart Supply Chain and Smart Working) and base technologies (which include IoT, cloud services, big data and analytics).

Although different terms are used to refer to this phenomenon (“cloud manufacturing”, “smart manufacturing”, “intelligent manufacturing”, etc.), there are commonalities between them (Culot et al., 2020): (1) Key enabling technologies, characterised by increasing digitalisation and connectivity due to physical-digital interface, network, and data-processing technologies and the key role played by the IoT and cloud computing; (2) Distinctive characteristics, which are the technology properties of virtualisation, real-time information sharing, and autonomy, plus greater process integration within and across the company boundaries, interoperability and cybersecurity solutions; (3) Possible outcomes, which mostly relate to higher productivity and flexibility, making mass customisation possible.

2.2The concept of servitisationThe term “servitisation” was coined by Vandermerwe & Rada (1988) and means transitioning from the long-established practice of selling products and basic support services to providing advanced combinations of products and services so that greater value is procured for customers by, for example, providing availability. A concept closely linked to servitisation is that of product-service systems (PSS). Tukker (2004) envisages different forms of PSS that include product-oriented services, use-oriented services and result-oriented services.

Neely (2013) sees servitisation as a journey of transformation towards new ways of seeing the relationship between users and suppliers of assets, based more on the provision of services than on the delivery of actual goods, giving rise to cooperation between parties based on long-term contracts.

2.3The concept of re-shoringMore recently, researchers have detected a number of firms that have reconsidered their previous offshoring decisions and relocated value chain activities, particularly production (Pedroletti & Ciabuschi, 2023). As re-shoring is closely linked to their previous offshoring decisions, when potential benefits of offshoring such as favorable environment, learning opportunities, efficiency and flexibility decrease, firms may start considering the option of bringing back operations to their home country or region in order, for instance, to increase control, offset location problems or even obtain potential new benefits from new policies targeting re-shoring (Pedroletti & Ciabuschi, 2023).

Empirical evidence confirms that these processes have been on the increase in the past 10 years (Dikler, 2021; Raza et al., 2021), and that larger corporations and medium and high-technology industries are most likely to re-shore (Raza et al., 2021). This means that high-end, technology-intensive manufacturing which requires the right infrastructure, skilled workers, intellectual property safeguards and integrated supply chains is increasingly finding that domestic production is the least expensive, most efficient option (Bolter & Robey, 2020). Thus, there is more and more discussion of the vulnerability of GVCs, of the trend for production and sales networks to regionalise more in the context of “slowbalisation” (Raza et al., 2021) and of a regional rebalancing of some GVCs, resulting in a more varied, more scattered production map (De Backer et al., 2016).

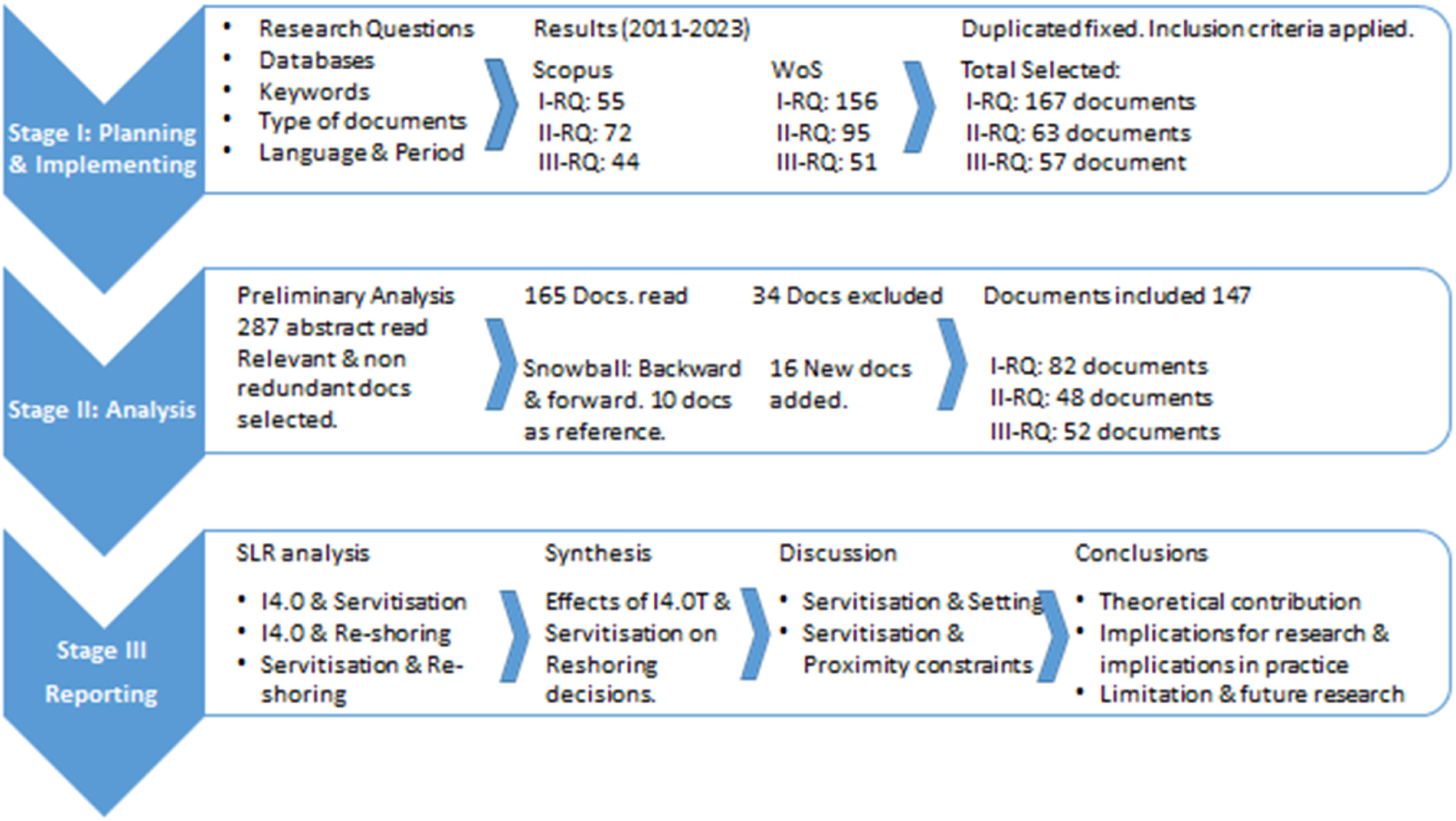

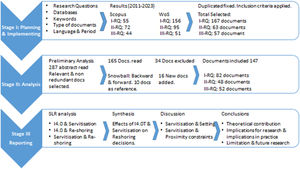

3Methodology: a systematic literature reviewWe conduct a systemic literature review (SLR) to identify, synthesise, assess and interpret the findings of past studies and address the research question analysed here, i.e. how the academic literature to date on I4.0 and servitisation has addressed the relation between these concepts and reshoring processes. The main value added of this review is the classification of literature, interpretation of findings and identification of gaps.

The field of research addressed by this paper is broad, and covers three main topics: I4.0, digital servitisation and reshoring processes. To conduct a thorough literature review, we decided to split our systemic search into 3 research questions (RQ1, RQ2 & RQ3) and follow a pairwise analysis first to review whether academic literature has addressed each link, and second to analyse what kind of link there is.

We used a combination of strategies to carry out a thorough SLR. On the one hand, we follow the procedures detailed by Dekkers et al. (2022), who set out a multidisciplinary guide to systematic approaches, and the papers of Gatell & Avella (2024), Pucheanu et al. (2022) and Reis et al. (2020), Rejeb et al. (2022), since their SLRs also involve the crossroad between different concepts. On the other hand, to identify additional relevant publications, we also applied snowball and citation search procedures. The SLR comprises three stages: planning and implementing, analysis and classification and reporting of results (Atif et al., 2021; Pucheanu et al., 2022; Reis et al., 2020; Rejeb et al., 2022).

In the first stage, the literature review planning protocol is established and implemented: the research questions are formulated, the key words and terms chosen, the research period set, the search databases selected, and inclusion and exclusion criteria established.

Scopus and the Web of Science (WoS) were selected for the SLR as they are among the most important scientific databases and the documents contained in them are peer-reviewed, which assures their quality (Rejeb et al., 2022). The search was limited to publication dates from 2011, when the term “Industry 4.0′' was first coined to 2023. The terms entered in Topic/Keywords for database research are pairwise:

- I.

Pair: I4.0 & Servitization (Servitisation);

- II.

Pair: I4.0 & Re/Back-shoring/Nearshoring; Smart manufacturing & Re/Back-shoring/Nearshoring; Cloud manufacturing & Re/ Back-shoring/ Nearshoring;

- III.

Pair: Servitisation & Re/Back-shoring/Nearshoring; PSS & Re/Back-shoring/ Nearshoring; Digital Servitisation & Re/Back-shoring/Nearshoring; Digital Servitisation & Territorial dynamics; Servitisation & Territorial dynamics; PSS & Territorial dynamics.

As inclusion criteria, “Article”, “Book”, “Book chapter”, and “Review article” written in English were considered, and Meeting, Editorial Material and Conference Proceeding were excluded. For each document, preliminary relevance was determined by title, abstract and keywords. In this stage, duplicated results were fixed. If the paper passed this initial examination, the full reference was obtained for further assessment in the second stage.

In Stage II, preliminary analysis, we reviewed 287 documents’ title, abstract and keywords. Inclusion criteria being relevant & non-redundant, 165 papers were selected for full texts reading and extracted information from papers for crosschecking. The inclusion criteria were their links to the main research topic, relevancy and non-redundancy. In each pairwise analysis, we focused on issues related to territorial dynamics, reconfiguration of value chains, supply chains, technology and proximity constraints, to include papers directly or indirectly related to reshoring processes. Documents not close to any of these recurrent topics were excluded as irrelevant: 122 in the preliminary analysis and 34 in the full text reading.

As a complementary snowball and citation review, we identified an initial set of papers and assessed their references and citations. These papers were the following ten documents: Martín-Peña et al., 2018 (cited 218); Paschou et al., 2020 (cited 337); Marcon et al., 2022 (cited 11); Kohtamäki et al., 2019 (cited 719) & 2022 (cited 41); Kolagar et al., 2022 (cited 57), Fratocchi & Di Stefano, 2019 (cited 54) & 2020 (cited 15); Wiesmann et al., 2017 (cited 245); and Cosimato & Vona, 2021 (cited 26). As a result, we included 22 further papers to read, and finally, based on a full reading decided to include 16 of them.

The Stage III of this SLR process, reporting, is summarised in the Fig. 1, and its development and in-depth analysis is presented in the following sections of this article.

4Results4.1RQ1: Industry 4.0 and servitisationDigital technologies are encouraging manufacturing firms to press ahead with servitisation by speeding up the offering of integrated products and services in the creation of new value and by strengthening relationships with customers in the era of I4.0 (Pirola et al., 2020) and at the same time enabling the implementation of the circular economy paradigm into businesses (Atif et al., 2021; Bressanelli et al., 2020; David et al., 2021; Langley, 2022; Rejeb et al., 2022) and new business models (Agostini & Nosella, 2021; Chen et al., 2021; Kohtamäki et al., 2019; Paiola & Gebauer, 2020; Weking et al., 2020).

According to Paiola & Gebauer (2020), data gathering and analysis is what allows companies to devise a series of servitized value propositions enabled by IoT that are at the base of the redefinitions of the business model. Smart connected products and its generated digital services constitute the fundamental composition of the Smart PSS, which undertake an IT-driven value co-creation manner to fulfil customer needs (Zheng et al., 2019). This results in terms such as “digital servitisation”, which refers to the provision of services enabled by ICTs, based on digital components integrated into physical products (Vendrell-Herrero et al., 2017). Therefore, digital servitisation could become the trigger for a transition from property-based to non-property-based business models, driving advanced revenue models such as pay-per-use, subscription or shared use, introducing a completely new value capture mechanism (Paiola & Gebauer, 2020) and establishing reciprocal formulas for sharing risks and rewards between providers and users (Kamp et al., 2017).

Digital servitisation creates business model complexities, such as conflicts between digital and physical service offerings, clashes between new ecosystem partnerships and traditional supply chain relationships, or digital revenue models and product sale models (Chen et al., 2021). The evidence suggests that various categories of competencies allow for different paths of digital servitisation, but that success in digital servitisation requires an appropriate mix of technical, methodological, personal and social skills (Cimini et al., 2021).

In this sense, the advent of digital servitisation has created new challenges in terms of the capabilities needed by companies, with companies’ internal capabilities, ecosystem-related and networking capabilities playing an increasing role (Favoretto et al., 2022; Münch et al., 2022; Smania et al., 2022). Thus, digital servitisation transforms the business ecosystem, its supply chains and business relationships (Grandinetti et al., 2020). Therefore, digitisation not only affects the business models of individual companies, but also involves the alignment of the business models of other companies within the ecosystem (Kohtamäki et al., 2019). Ad hoc production networks and the integration of the supply chain are among the main drivers of digital servitisation (Gaiardelli et al., 2021), as the complexity of digital solutions creates a need for customer organisations to consider suppliers as strategic partners working side by side (Sjödin, Kamalaldin, Parida, & Islam, 2023) and intense cooperation between suppliers and (key and selected) customers is a fundamental trait of the most advanced cases of digital servitisation (Grandinetti et al., 2020).

In fact, many digital servitisation initiatives fail due to lack of ecosystem partnerships to ensure value creation (Kolagar et al., 2022). Studies on digital servitisation and business models have emphasized the role played not only by customers, but more broadly, by the actors in the business ecosystem in supporting business model innovations (Agostini & Nosella, 2021), whose governance is considered one of the main challenges. Digitization implies the decoupling of information from devices and technologies, which leads to the dispersion of knowledge creating the need to collaborate, not only with the internal actors of the organization, but also with the actors that are outside the limits of the company (Sklyar et al., 2019). Thus, apart from digitalization capabilities, firms need to develop relational capabilities, such as, providing internal coordination and maintaining external visibility, learning to integrate and coordinate value cocreation activities (Galvani et al., 2022), exploiting current actor competencies through effective knowledge transformation (Kolagar et al., 2022), and design new front-end and back-end roles (Galvani et al., 2022). As a result, issues linked to the culture of transparency and openness, and accountability and trust (Kamp et al., 2017; Kolagar et al., 2022), ethics and security are fundamental in attaining the closest possible convergence between servitisation and I4.0 (Frank et al., 2019b; Kamp et al., 2017).

Finally, firms that implement services benefit from strategic associations with knowledge-intensive service businesses (Bustinza et al., 2017; Paiola et al., 2013). The evidence suggests that the development of smart PSS requires a context of strong technological potential that offers the resources for its development, as well as a support infrastructure and knowledge among stakeholders (Liu et al., 2019; Wang et al., 2022). Moreover, an analysis of the main regional context conditions for 4.0 technological transformation reveals the importance of innovation, education, creativity and entrepreneurship, digital literacy and the presence of a vibrant fabric of industry and local economy (Capello & Lenzi, 2021). This gives rise to the concept of territorial servitisation, which goes beyond organisational limits and brings together the overall results of the various types of mutually dependent association that manufacturing and knowledge-intensive service businesses set up and develop within a specific territory (Lafuente et al., 2017). Interactions between firms and related service businesses at regional level encourage flows of knowledge not just between them, but also to and from various actors in the local value chain. This strengthens both the original fabric of industry and local economic development and resilience, enabling firms also to develop relational and absorption-based capabilities (Gomes et al., 2019).

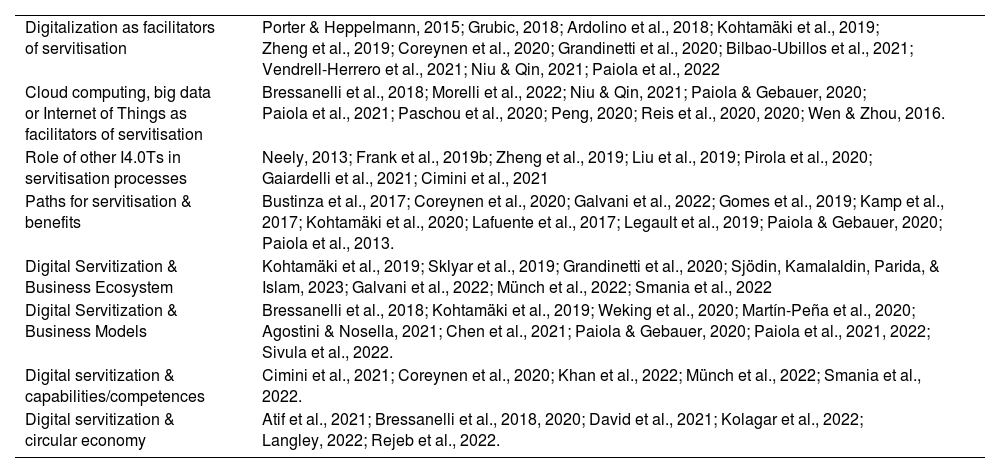

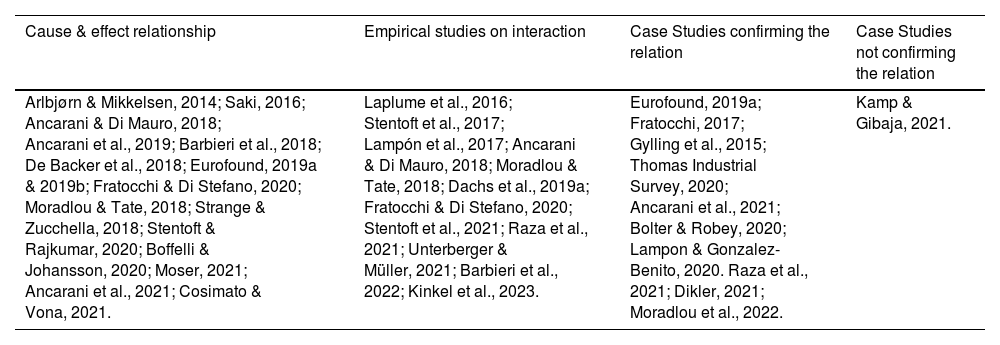

Table 1 shows the interactions between I4.0 and servitisation detected in our SLR.

Interactions between I4.0 and servitisation in the SLR.

Source: Own elaboration.

Until recently, little attention was paid to the link between I4.0 and re-shoring (Dachs et al., 2019a), but it is now sparking considerable interest in the relevant literature (Ancarani & Di Mauro, 2018; Ancarani et al., 2019; Dachs et al., 2019a; De Backer et al., 2018; Fratocchi & Di Stefano, 2020). The application of I4Ts is bringing about a transformation in manufacturing industry, in terms of both the make-up of processes and the products on offer. Changes are taking place in the cognitive composition of the knowledge bases of the technology solutions used, and in the composition, morphology and geography of value chains, all of which affects re-shoring processes at companies (Bilbao-Ubillos et al., 2021).

First of all, certain territorial dynamics potentially affecting relocation decisions should be considered: Stentoft et al. (2021) indicate that the qualifications required to handle Industry 4.0 technologies may decrease the willingness of firms offshore and increase the likelihood of re-shoring. Kinkel et al. (2023) also highlight the importance of digital skills in the operation of new technologies associated with artificial intelligence (AI) and point out that they act as drivers fo back-shoring decisions.

In line with the operational complexity involved in handling Industry 4.0 technologies, Lampón et al. (2017) highlight the importance of technology-related demands in the design of relocation strategies as a result of the resources and capacities that host territories must offer if they are to handle new technologies efficiently. Barbieri et al. (2022) highlight that the development of policies to drive Industry 4.0 provides an opportunity to generate location advantages that can attract home-country firms located abroad.

But aside from these studies, which have in common the facts that technology is a determinant factor in location and that the development of Industry 4.0 is conducive to back-shoring. Bailey & De Propris (2014) highlight other aspects: They focus on the case of the UK automotive industry and state that a combination of a more competitive exchange rate (despite the very recent appreciation of sterling), increased transport costs, rising wages in key areas of China, and a greater awareness of supply chain resilience have all contributed to a perceived change in some business ‘fundamentals’. The potential for some supply chain re-shoring also links in with the trend of the ‘servitisation’ of manufacturing, including the auto sector, and shift to a hybrid model where manufacturing and services are increasingly intertwined (Bailey & De Propris, 2014, 60).

But in our opinion, technology and know-how are determinant factors in re-shoring decisions for the following reasons: First, there is a greater combinatorial and technological complexity in support knowledge due to the incorporation of the new knowledge fields needed by the process of digitalisation of manufacturing production. This incorporation of new knowledge fields also increases the cognitive content of tasks, given that new technologies must be incorporated in a specific fashion with specific technical results required in the context of the new solution drawn up. Any effort to adapt technically will always require a process of investigation which is specific to each product/process. Making such specific adaptations calls for sufficient technology potential to carry out the necessary cognitive synthesis.

Secondly, the new knowledge entailed by digital technologies is science-based and features a high degree of novelty (latest generation), so it can be expected to have a large tacit component. This is liable to involve proximity constraints for efficient transfer. Moreover, the great scope of digital technologies for generating new applications in all directions means that they can be expected to develop rapidly, offering new, more efficient, more comprehensive practical possibilities and calling continually for the adaptation of technology (Bilbao-Ubillos et al., 2021).

Thirdly, changes in the cognitive content of technical solutions affect both the organisation and composition of value chains (with participants potentially joining and leaving), changing the relationships established between participants. This not only conditions the shape of value chains but also shifts them towards more complex forms of governance that entail more intensive proximity constraints (Gereffi & Lee, 2012). Thus, in re-shoring decisions there is a need to assess the risk of losing technical knowledge and access to knowledge (both within the firm and in the local network), as this could act as a barrier to re-shoring (Boffelli & Johansson, 2020). Some experiences show a positive relationship between the success of the re-shoring strategy through I4.0 and the preparation of the local ecosystem, so that the company is able to absorb the tacit knowledge of its local system (Pegoraro et al., 2022).

There is agreement in economic literature that the effects of digitalisation on employment are marked by two basic tendencies: in one jobs are reduced as a result of process automation, and in the other there is an increase in the qualifications required of human resources to work with the new products and processes (Autor, 2015; Bonekamp & Sure, 2015).

The greater cognitive complexity of the technical solutions in manufacturing poses a problem of adaptation to new production requirements. There is a need for personnel trained in new qualifications and the skills needed to assimilate new knowledge and adapt it to new technical solutions so as to operate efficiently. This in turn calls for a cognitive rethinking at businesses in which priority must be given to personnel training (Kamp & Gamboa, 2021; Kohtamäki et al., 2019). As the core role of digital technologies grows, this may necessitate the implementation of a digital culture at organisations.

Therefore, the setting where production is located must have a supply of labour with the required skill sets (Eurofound, 2019b; Strange & Zucchella, 2018), because skill shortages are an issue to be considered in re-shoring (Boffelli & Johansson, 2020; Lampón & Gonzalez-Benito, 2020; Moradlou et al., 2022). Thus, countries performing well in human capital, education, innovation, network readiness and digitalisation will be well placed to take advantage of re-shoring decisions (Bonekamp & Sure, 2015).

In the last 2 decades authors insist on the changing patterns of production relocation (Fan & Liu, 2021). Some developed countries have proposed plans for “re-industrialization” and “manufacturing recovery” to restore their own economies and adopted different levels of protectionist measures (Stentoft et al., 2016).

The cases covered in economic literature confirm that technology is a key explanatory factor in re-shoring. Stentoft & Stegmann (2014) conclude that the need for greater proximity between R&D and production to take advantage of technological opportunities is one of the conditioning factors for re-shoring decisions. Thus, re-shoring is justified by the increasing importance of innovation and quality, which can be boosted through the location of R&D and production centres closer to the end customer, and by the need to safeguard intellectual property rights.

Kinkel (2014) and Dachs et al. (2019a) highlight quality and the flexibility to respond rapidly to customised demand as key factors for re-shoring, but transport and coordination costs, staff qualification problems and proximity to R&D activities are also important (Kinkel, 2014, 64; Dachs et al., 2019b). Kamp & Gibaja (2021) do not find any clear impact of I4.0Ts on backshoring operations in their study, but Ancarani et al. (2019), Cosimato & Vona (2021) and Barbieri et al. (2018) observe a link between re-shoring and I4.0Ts. Ketokivi et al. (2017) observe that the technologically highly complex activities that involve highly specific knowledge, with low levels of codification, are more likely to re-shore. Lampón & Rivo-López (2021) find that in highly technology-intensive industries an innovation-oriented strategy drives re-shoring strategies, while in low-technology sectors a cost-oriented strategy prevails.

Moser (2013) states that the loss of operational flexibility, the reduction in innovation potential and difficulties in finding qualified personnel are among the basic reasons that drive re-shoring processes.I4.0 thus encourages re-shoring whenever bringing the value chain back together is important for developing products, creating prototypes, etc. In such cases, joint location of production and development may become a source of value creation, and new manufacturing technologies can help reduce production costs (Ancarani & Di Mauro, 2018).

Once it is realised that there are generally links between I4.0 and re-shoring, it must also be understood that the various technologies involved in I4.0 may have different effects on re-shoring (Ancarani & Di Mauro, 2018; Fratocchi & Di Stefano, 2020; Raza et al., 2021). In industries with higher labour costs, locating to developed countries has only recently become economically viable because of the increasing degree of process automation (Stentoft et al., 2017). However, Raza et al. (2021) state that automation can also be conducive to offshoring, as it helps to strengthen the productivity of production processes in emerging economies. And Ancarani & Di Mauro (2018) conclude that robotics is not a necessary ingredient for re-shoring.

Of the various technologies involved in I4.0, robotics is best suited to customised manufacturing, benefiting industries where market demand and consumer preferences change rapidly. In such industries, robots enable firms to bring new products to the market far more quickly than with offshoring, which often involves distant countries where suppliers do not always produce to the correct specifications, resulting in quality problems and long lead times (De Backer et al., 2018).

Big data analysis and digitalisation increase the ability to coordinate operations remotely, which may make re-locating to low-cost countries an attractive prospect (Ancarani & Di Mauro, 2018), but additive manufacturing technologies have a positive impact on decisions to re-shore, pushing value chains to become more local and move closer to end-users (Fratocchi, 2017; Moradlou & Tate, 2018; Raza et al., 2021). This is especially true of re-shoring decisions made on quality grounds (Ancarani & Di Mauro, 2018). Specifically, Moradlou & Tate (2018) identify 6 areas where additive manufacturing may potentially impact the supply chains of companies, making them more receptive to re-shoring: shorter lead times, better response in terms of product and market changes, lower transport costs, fewer communication errors with suppliers, more customisation options and lower product inventories in stock.

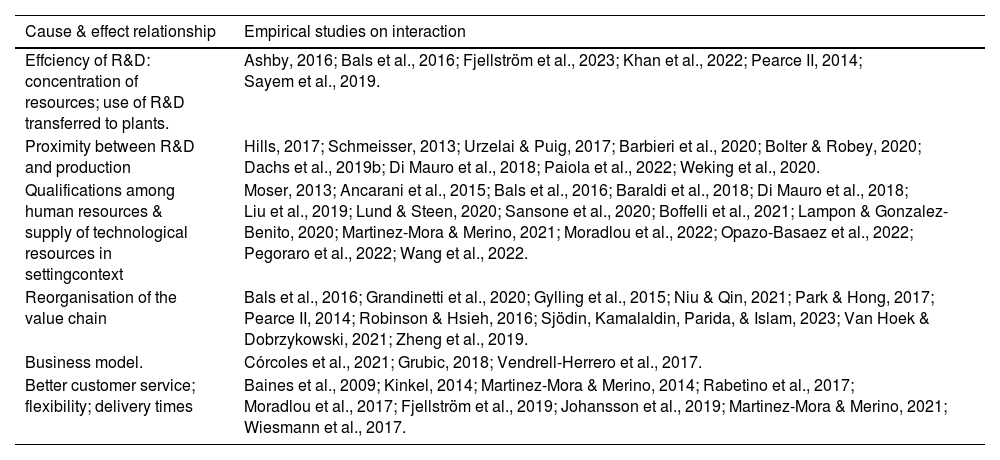

As can be seen (Table 2), academic interest in the link between re-shoring and I4.0 has grown over time, though for the moment there is limited empirical evidence (Dachs et al., 2019a; Raza et al., 2021).

Interactions between I4.0 and Re-shoring in the SLR.

Source: Own elaboration.

The symbiosis between digitalisation and servitisation has major cognitive consequences for business operations (Peng, 2020; Ruiz de la Torre & Sánchez, 2022). The high levels of innovation and the scientific basis of supporting knowledge (Pucheanu et al., 2022; Zheng et al., 2019) mean that the tacit component of the knowledge used acquires a core role, which leads to major proximity constraints in transfer processes. Despite the benefits of better communication, some types of knowledge are so tacit in nature that only spatial proximity (e.g. co-location) can enable them to be absorbed by actors throughout the value chain (Baldoni et al., 2022). In fact, in the case of SMEs, servitised firms are more likely than non-servitised firms to engage in innovation activities, to use absorptive capabilities in the appropriation of external knowledge and to collaborate with partners in the innovation process (Punstein & Glückler, 2021).

At the same time, servitisation processes encourage the reorganising of production operations based on platforms that can support the customer and supplier integration needed to achieve efficient collaboration on technology between all stakeholders (Grandinetti et al., 2020; Niu & Qin, 2021; Zheng et al., 2019). Such collaboration is needed to adapt to faster technical dynamics and be open to changes in business models, so as to take advantage of the opportunities offered by changing circumstances (Barbieri et al., 2020; Bolter & Robey, 2020; Dachs et al., 2019b; Di Mauro et al., 2018; Eurofound, 2019a; Paiola et al., 2022; Weking et al., 2020). This conditions the shape of value chains and brings about a shift towards more complex forms of governance in which proximity constraints play a greater role (Gereffi & Lee, 2012).

The business models used will call for ever-higher levels of skill and qualifications among customers and suppliers too, and for powerful telematic infrastructures (both public and private) to support new operational requirements (Liu et al., 2019; Wang et al., 2022). This in turn calls for physical proximity between stakeholders as a key part of assuring rapid response and the opportunity to acquire critical knowledge of customers’ operations and needs (Strange & Zucchella, 2018). It also requires customers and suppliers to be located in a setting where the technology resources needed to take part in an integrated, advanced process are available (Sjödin, Kamalaldin, Parida, & Islam, 2023).

The literature that analyses reshoring processes on the basis of case studies confirms the link between digital servitisation and reshoring. These findings show the core role of the technical and organisation requirements associated with digital servitisation in explaining reshoring. The need to make good use of knowledge transfers to production plants (Ashby, 2016; Fjellström et al., 2023; Sayem et al., 2019), the need to be close to customers and markets (Fjellström et al., 2019), access to human resources with the necessary qualifications and skills (Boffelli et al., 2021; Lampon & Gonzalez-Benito, 2020; Moradlou et al., 2022; Moser, 2013), the efficient reorganisation of supply chains (Park & Hong, 2017; Robinson & Hsieh, 2016; Van Hoek & Dobrzykowski, 2021) and the need for R&D and production operations to be close to each other (Bals et al., 2016; Pearce, 2014) are also relevant factors. All these circumstances share the need to locate production plans in a setting where they can adapt their technologies to new production requirements (Lund & Steen, 2020; Pegoraro et al., 2022). Reshoring is an effective way of doing this.

Finally, secure data exchange (Kagermann & Wahlster 2022) and cybersecurity are an issues raised by digital servitization; in some cases, reshoring is a better option than offshoring in terms of control, cost and risk (Engström et al., 2018; Moretto et al., 2020; Park & Hong, 2017; Sayem et al., 2019). Another factor is the customer's perception of value, which still has a pivotal role in back-shoring decisions (Moradlou et al., 2022), as does ethnocentrism, i.e. consumers’ tendency to exhibit a positive predisposition toward products made in their home country (Grappi et al., 2015).

Table 3 shows the main general interactions between servitisation and reshoring detected in the SLR.

Interactions between Servitisation and Re-shoring in the SLR.

Source: Own elaboration.

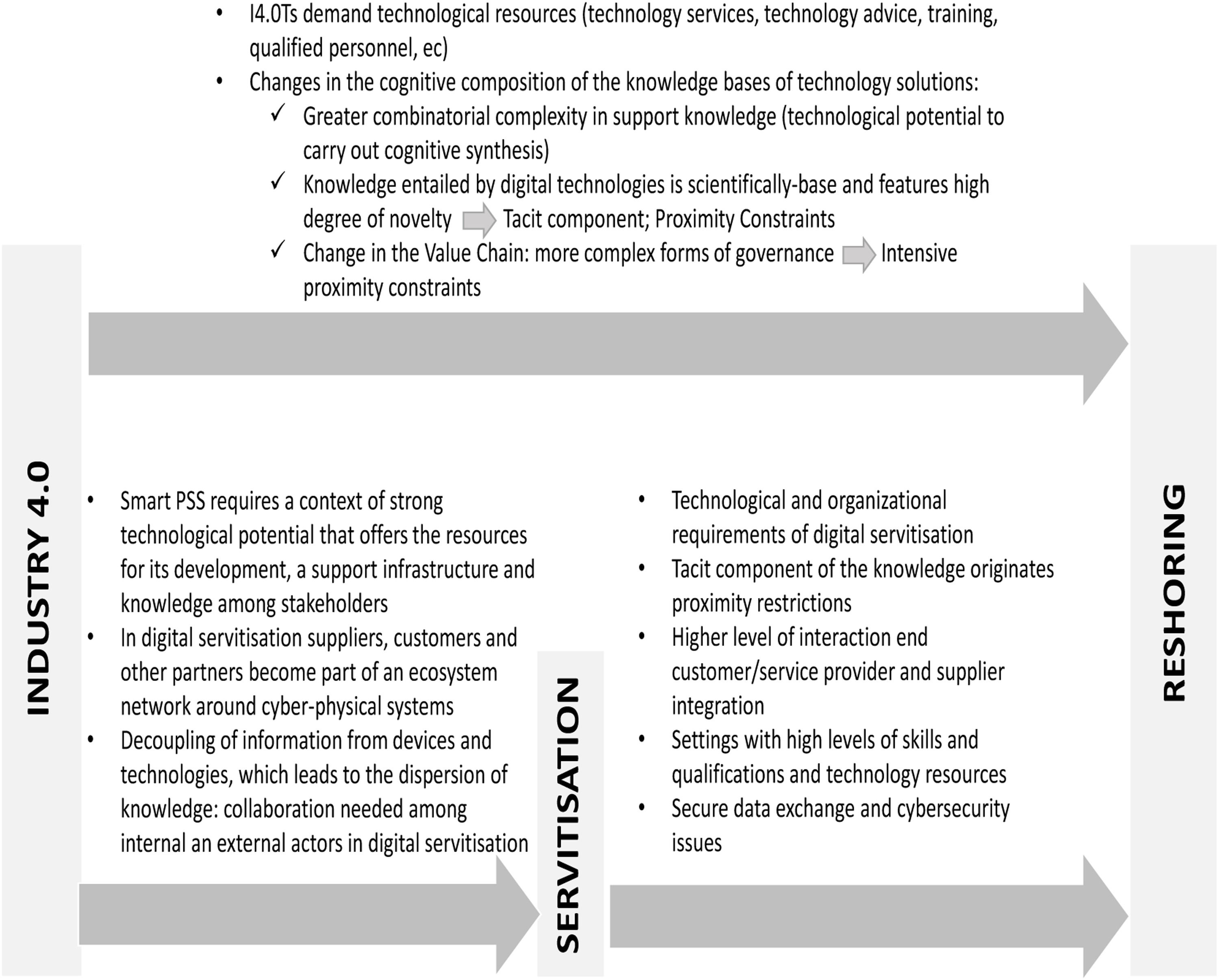

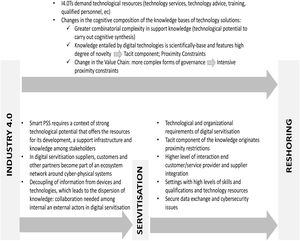

The SLR conducted focuses on pairwise comparison of the three thematic terms. It enables us to explore how I4.0Ts and servitisation may be affecting business decisions in regard to re-shoring (Fig. 2).

As the SLR shows, the scenario entailed by I4.0Ts and servitisation strategies intensifies the need for greater proximity and closer collaboration between the actors involved in generating new, innovative solutions, as the cognitive complexity of the knowledge bases of the technology solutions will make companies more dependent on external networks and will generate proximity constraints. Servitised designs are set to increase the intensity and frequency of customer/supplier relations greatly, and in the framework of the sharing of highly-novel, scientifically-based knowledge they entail strong proximity constraints, which become a very powerful conditioning factor for location.

On the other hand, I4.0Ts lead to digital servitisation processes in which the technological capabilities of companies and the territories where they are located acquire great relevance. They require settings with high-level technology resources and human skills, and entail a need to increase collaboration between ecosystem actors, all of which may be expected to have a major impact on re-shoring decisions.

5Discussion of findings and conclusions5.1Servitisation and settingServitisation increases the complexity of the production system via the incorporation of I4.0Ts into corporate operations in the form of a more extensive, deeper integration. This also affects firms’ relations with technology-centred institutions and with customers and suppliers. Efficient servitisation entails close links with customers and suppliers that go beyond new technical assistance. Customers and suppliers will report needs, propose solutions, etc. that will have far-reaching consequences in terms of location, because there will be circumstances that require proximity for cooperation to be efficient, and clients and suppliers will need to located in a setting where they have the potential to provide themselves with the resources to take part in an integrated, advanced process (Sjödin, Kamalaldin, Parida, & Islam, 2023).

The technology setting will play a core role in the supply of human and technological resources, and in providing a fabric of production that meets the requirements for the business model set up to be efficient. The resources offered by the setting will mark the potential for advancement in developing smart manufacturing capabilities (Khan et al., 2022; Vaillant et al., 2021). A weak setting forces firms to opt for specialised solutions with a more limited scope, which may be of interest in the short term but offer less of a future (Legault et al., 2019). The choice of a location for industrial operations is an increasingly selective process (Taleb et al., 2022). In short, location becomes increasingly important as servitisation becomes more sophisticated and calls for a more complex, more efficient organisational model.

5.2Servitisation and proximity constraintsAs emerging technologies with a high degree of novelty, the development of servitisation is characterised by the prominent role played by basic knowledge, and thus by a substantial tacit component in information transfer processes. The rate of change in the technical solutions arising from the huge capacity of I4.0Ts for generating new applications thus necessitates frequent, rapid changes. This in turn necessitates continual recourse to settings capable of handling the necessary adaptations. The tacit component and the frequency of interactions with external factors strengthen the role of proximity in the factors involved in the dynamics of technology (Baldoni et al., 2022). Moreover, the wealth of recombinations offered by I4.0Ts makes for a scenario with high levels of uncertainty in terms of goals and paths. This highlights the importance of locating in settings with a high potential for the provision of I4.0Ts that can cater for as-yet-undefined future cognitive needs. Proximity ensures a scenario in which interactions multiply to give rise to unexpected new solutions (De la Torre & Sanchez, 2022; Foray & Goenaga, 2013).

The extension of servitisation increases the need for integration with the other agents needed for it to operate. Technology-related problems are not limited to the adaptation and development of new technical solutions at corporate laboratories but extend to the make-up of links with all the public and private sector organisations associated with the operation of companies, especially customers and suppliers. Links in which the cognitive content has a high tacit component and there is continual interaction strengthen proximity constraints between agents and, equally importantly, call for a localised fabric of customers and suppliers in a setting where there is a high level of I4.0Ts on offer. This can be thought of as a highly powerful territory effect that justifies the emphasis placed by Mattes (2012) on geographical proximity as a facilitator of other forms of proximity (social, organisational and institutional) which are important for the efficient operation of activities that require a high level of integration between participants.

5.3Conclusions5.3.1Theoretical contributionI4.0Ts, and particularly increased digitisation, has made for the configuration of new business models and the servitisation of the economy in the context of a new paradigm of competition. This digital servitisation is conducive to networking and enhances the role of proximity. Together with other concurrent factors, this is favouring re-shoring. The process drivers directly concerned with technology are the following:

- -

Changes in relative costs: the automation of processes entailed by I4.0 is reducing the amount of labour required per unit of product and thus the significance of labour costs as a factor for offshoring.

- -

Agglomeration economies entailed by digital servitisation. On the one hand there is the greater density of firms and the greater complementarity between them that can be found in more developed countries (which are generally the sources of capital), which is significant for PSS. On the other hand there is the need for technology infrastructure in the host country (technology centres, engineering firms), which is increased by the greater combinatorial complexity of the supply of firms.

- -

The advantages of proximity to end markets entailed by digital servitisation: the ability to respond quickly and flexibly to market changes, manufacture customised products, shorten development periods and reduce waste. Offshoring took production plants away from developed countries, so that the potential that now emerges from customisation arising from digital servitisation was lost. The demand for better customer service leads to a need for greater proximity because the content of that service is cognitively more complex and the market for more evolved (servitised) production processes lies precisely in higher income countries (the source countries of the investment made abroad for cost reasons). This is conducive to reshoring. In activities where emerging markets are also significant it is possible that not all production may be reshored, but at least part of it will be, so as to provide a fast response to customers in developed countries.

- -

The skills and expertise in data management required by I4.0Ts: wider availability in the developed countries that tend to be sources of FDI.

In turn, these factors conducive to proximity benefit from the need to address uncertainties in exchange rates, interest rates, trading policies (the tendency towards protectionism), in the economic consequences of potential conflicts or pandemics (supply chain disruption) and in undesirable inventory levels. These uncertainties make locating production in other settings a less attractive prospect.

Factors that offset this push towards re-shoring include sunk costs and the need of component suppliers to be close to the plants of their customers when they work on a just-in-time basis, or when the end product of firms is aimed at distant markets.

Implications for research and implications in practice:

This study focuses research and corporate decision-making on the role of proximity in the new technology setting that stems from digital servitisation, and therefore it provides managers with a detailed overview of the main factors for making re-shoring decisions.

The most significant implication for public authorities is concerned with the development of technological support in their reference territories to cater for training of personnel in digital skills and fostering and supporting technical assistance bodies in matters of digital technologies. In other words, the challenge is to design a context of support for production operations based on digital technologies, so as to prevent firms from leaving and encourage firms to set up in their areas (reshoring).

Our work is not without limitations. First, SLR applies a well-structured, rigorous method. However, some studies may potentially have been excluded due to research decisions such as database and keyword selection, publication type and language. In any case, we believe that the publications identified are representative of the current literature. Second, I4.0 is a general concept for a wide range of technologies and applications, and each of those technologies could have a different impact on servitisation and reshoring. Therefore, future research could focus on the study of these relationships. More specifically, how do the different I4.0Ts affect digital servitisation and reshoring processes? Do all the technologies that fall under I4.0 work in the same direction?

Our study offers indications of the potential links between digital servitisation and re-shoring in general, without establishing nuances depending on the type of company in question. Therefore, another important line of research could be to study the link between digital servitisation and re-shoring depending on the sector of activity of the company or its position in the value chain. Finally, recent studies show the role of I4.0 in the implementation of the circular economy in the servitisation business model (Atif et al., 2021). In the context of these business models, to what extent will the drive towards the circular economy boost re-shoring processes?

FundingThe authors acknowledge research funding from Basque Government (GIC21/113 BILBAO UBILLOS, JAVIER).

CRediT authorship contribution statementJavier Bilbao-Ubillos: Conceptualization, Project administration, Supervision, Writing – review & editing. Vicente Camino-Beldarrain: Methodology, Formal analysis, Writing – original draft, Writing – review & editing. Gurutze Intxaurburu-Clemente: Writing – original draft, Writing – review & editing. Eva Velasco-Balmaseda: Investigation, Data curation.

Agostini & Nosella (2021), Ancarani & Di Mauro (2018), Ancarani et al. (2015), Ancarani et al. (2019), Ancarani et al. (2021), Ardolino et al. (2018), Arlbjørn & Mikkelsen (2014), Ashby (2016), Atif et al. (2021), Baines et al. (2009), Bals et al. (2016), Baraldi et al. (2018), Barbieri et al. (2018, 2020, 2022), Bilbao-Ubillos et al. (2021), Boffelli & Johansson (2020), Boffelli et al. (2021), Bolter & Robey (2020), Bressanelli et al. (2020), Bressanelli et al. (2018), Bustinza et al. (2017), Chen et al. (2021), Cimini et al. (2021), Córcoles et al. (2021), Coreynen et al. (2020), Cosimato & Vona (2021), Dachs et al. (2019a, 2019b), David et al. (2021), De Backer et al. (2018), Di Mauro et al. (2018), Dikler (2021), Eurofound (2019a, 2019b), Fjellström et al. (2019, 2023), Frank et al. (2019b), Fratocchi (2017), Fratocchi & Di Stefano (2020), Gaiardelli et al. (2021), Galvani et al. (2022), Gomes et al. (2019), Grandinetti et al. (2020), Grubic (2018), Gylling et al. (2015), Hills (2017), Johansson et al. (2019), Kamp & Gibaja (2021), Kamp et al. (2017), Khan et al. (2022), Kinkel (2014), Kinkel et al. (2023), Kohtamäki et al. (2019), Kohtamäki et al. (2020), Kolagar et al. (2022), Lafuente et al. (2017), Lampon & Gonzalez-Benito (2020), Lampón et al. (2017), Langley (2022), Laplume et al. (2016), Legault et al. (2019), Liu et al. (2019), Lund & Steen (2020), Martín‐Peña et al. (2020), Martinez-Mora & Merino (2014, 2021), Moradlou & Tate (2018), Moradlou et al. (2017), Moradlou et al. (2022), Morelli et al. (2022), Moser (2021, 2013), Münch et al. (2022), Neely (2013), Niu & Qin (2021), Opazo-Basaez et al. (2022), Paiola & Gebauer (2020), Paiola et al. (2013, 2022), Paiola et al. (2021), Park & Hong (2017), Paschou et al. (2020), Pearce (2014), Pegoraro et al. (2022), Peng (2020), Pirola et al. (2020), Porter & Heppelmann (2015), Rabetino et al. (2017), Raza et al. (2021), Reis et al. (2020), Rejeb et al. (2022), Robinson & Hsieh (2016), Saki (2016), Sansone et al. (2020), Sayem et al. (2019), Schmeisser (2013), Sivula et al. (2022), Sjödin et al. (2023), Sklyar et al. (2019), Smania et al. (2022), Stentoft et al. (2017, 2021), Stentoft & Rajkumar (2020), Strange & Zucchella (2018), Thomas Industrial Survey (2020), Unterberger & Müller (2021), Urzelai & Puig (2017), Van Hoek & Dobrzykowski (2021), Vendrell-Herrero et al. (2017), Vendrell-Herrero et al. (2021), Wang et al. (2022), Weking et al. (2020), Wen & Zhou (2016), Wiesmann et al. (2017), Zheng et al. (2019).