There is increasing awareness that customers and suppliers serve as key external information sources for the innovation of small and medium-sized enterprises (SMEs). However, existing research on the influence of customer participation (CP) and supplier participation (SP) remains inconsistent. This study addresses this gap by investigating how CP and SP affect different types of innovation performance of SMEs in China. Furthermore, by addressing the gap regarding the unclear mechanisms of CP and SP in SMEs’ innovation performance, this study explores the mediating role of a firm's absorptive capacity on innovation performance and the conditions under which absorptive capacity will be more effective. Based on a sample of 1861 SMEs in China, the findings highlight that CP positively impacts product innovation performance, with absorptive capacity acting as a partial mediator. Additionally, both CP and SP influence process innovation performance directly or through absorptive capacity. Meanwhile, the business environment moderates the effect of absorptive capacity on product innovation performance. These findings contribute to the theory of open innovation and offer valuable insights for SME managers, entrepreneurs, and scholars in enhancing innovation outcomes.

Small and medium-sized enterprises (SMEs) are becoming increasingly important for economic growth and innovation, particularly in China, where over 52 million SMEs contribute more than 60% of the GDP and employ over 80% of the workforce (OECD, 2024). SMEs play a critical role in China's overall economic and social development. They are extensively involved in markets and focus on the industrial chain, fostering integration and collaboration among enterprises of various sizes and academic institutions. This cooperation helps form a comprehensive industrial ecosystem, which is essential for maintaining the stability and competitiveness of supply chains (Zhou & Li, 2020). Despite their significance, Chinese SMEs face challenges, such as a high bankruptcy rate of 4.06% in 2020 (OECD, 2022), reflecting their fragility in a competitive market. Innovation is essential for SMEs to improve their market position and drive economic growth. Inter-organizational collaborations enable SMEs to leverage otherwise unavailable resources, creating value and fostering collaborative innovation, which benefits SMEs by pooling resources, sharing risks, and accessing diverse expertise (Ozdemir et al., 2023). Engaging external partners such as customers and suppliers provides direct feedback and market insights, which can reduce development time and costs, while aligning products with market needs (Greer & Lei, 2012). While some studies have explored the impacts of customer participation (CP) and supplier participation (SP) on innovation, there remain several research gaps this study aims to address.

First, there are inconsistent findings on the effect of CP and SP in innovation. While many studies demonstrate that CP and SP improve innovation performance (Li, 2023; Maria Stock et al., 2017; Yang & Shafi, 2020), some research contends that customer and supplier participation may have an adverse influence (Liu et al., 2022; Najafi-Tavani et al., 2022). These contradictory findings underscore the need for a more nuanced understanding of CP and SP's roles in innovation. Existing research has focused heavily on product innovation, often overlooking the significant role of customer and supplier participation in process innovation (Un & Asakawa, 2015). This research gap presents an opportunity to explore the influence of external stakeholders in various forms of innovation, potentially uncovering new mechanisms and impacts. Addressing this gap can provide a more comprehensive understanding of how collaborative effects in product and process innovation unfold, thus enhancing insights into the complexity and effects of customer and supplier participation in innovation processes.

Furthermore, research has extensively examined factors like manager’ traits (Maria Stock et al., 2017), firm context (Anning-Dorson, 2018), customer knowledge and experience (Luo & Toubia, 2015), supplier innovativeness (Kim & Chai, 2017), and consumer learning (Huang et al., 2014) from the perspective of customers, suppliers, or the focal firm. However, cross-organizational interactions between firms and customers/suppliers remain underexplored, even they are essential for effective knowledge sharing and dissemination (Cepeda-Carrion et al., 2023). Traditional approaches to product innovation have formed specific and well-defined methods, whereas methods following the knowledge-based view (KBV) have been less formalized. Knowledge collaboration is essential throughout the development process, and there have been calls to explore CP and SP from a knowledge management perspective (Cui & Wu, 2018). The KBV suggests that the essence of cooperation between customers/suppliers and firms is knowledge collaboration, with absorptive capacity being critical for effective knowledge sharing (Qu & Mardani, 2023). Although customer/supplier participation creates channels for knowledge transfer (Ozdemir et al., 2023), a lack of proper knowledge absorption can hinder the transfer of external knowledge (Tseng, 2016), leading to ineffective knowledge collaboration. A firm's absorptive capacity determines the effectiveness of knowledge transfer (Liu et al., 2018) and shapes the depth and facilitation of knowledge flows (Rupietta & Backes-Gellner, 2019). Therefore, it is essential to explore customer/supplier and firm interactions, particularly from the perspective of absorptive capacity (Qu & Mardani, 2023).

Moreover, the role of the business environment in influencing the effectiveness of collaborative innovation with customers and suppliers remains unclear. Previous studies have shown that innovation performance is influenced by the business environment where firms operate and compete (Jansen et al., 2006; Tsai & Yang, 2013; Yin et al., 2023). According to contingency theory, the knowledge collaboration factors that enhance innovation performance may not be as effective in other business environments. However, it is unclear under which business environment conditions CP and SP will function more effectively.

The research gaps identified above highlight a lack of comprehensive knowledge about whether and how CP and SP can promote innovation performance through absorptive capacity. This study seeks to address these gaps by exploring three questions: What is the influence of CP/SP on SMEs’ product and process innovation performance? How does absorptive capacity mediate the effect of CP/SP on innovation performance? Does the business environment moderate the relationship between absorptive capacity and innovation performance? To answer these questions, this study uses data from SMEs in China to examine the mechanism and condition through which CP/SP improves both product and process innovation performance. In doing so, this study makes three contributions to existing theories.

First, this study addresses the need for a deeper understanding of the complex mechanisms by which CP and SP influence innovation performance (Chang & Taylor, 2016). Although the existing research has explored the role of customer and supplier participation in product innovation, the specific impacts on process innovation remain less understood (Cui & Wu, 2018). This study strives to fill this gap by examining not only product but also process innovation.

Second, this study contributes to the literature by examining the mediating effects of absorptive capacity between CP/SP and product/process innovation performance, which addresses a critical research gap by focusing on the underexplored inter-organizational interactions between firms and customers/suppliers. By leveraging the KBV, this study highlights how absorptive capacity facilitates the effective transfer and application of knowledge in collaborative innovation with supply chain partners.

Finally, as the business environment is critical for collaborative innovation activities (Xie et al., 2023), this study examines the moderating effects of the business environment on collaborative innovation, contributing to the theoretical framework of open innovation by offering insights into how firms can navigate and leverage the complexities of their external environment to enhance innovation performance.

This study begins by examining the significant roles of customers and suppliers in innovation, then conducts a literature review and develops a conceptual framework to capture the mechanisms through which CP and SP influence product and process innovation performance. Methodology details the study's methodology, Results presents the key findings, and Discussion and implications offers the conclusions and discussion.

Literature reviewSupply chain collaboration of SMEsSupply chain collaboration (SCC) refers to cooperation between organizations to share resources and obtain external knowledge, enhancing the performance of supply chain members, including customers and suppliers (Fianko et al., 2023). By engaging in collaborative relationships, SMEs can achieve better resource allocation, reduce costs, and enhance responsiveness to market demands. However, some scholars argue that SCC can hinder the effectiveness and performance of SMEs. Challenges include a lack of technological infrastructure and expertise, which can impede effective communication and data sharing (Mahmud et al., 2021). Additionally, SMEs often hesitate to engage in collaborative efforts because of fears of potential innovation failures (Brunswicker & Vanhaverbeke, 2015). Conclusions regarding SCC's impact on innovation performance remain inconsistent, and further analysis from the perspective of customers and suppliers is needed.

Customer participation in innovationResearch on the relationship between CP and innovation has shown mixed results, indicating either positive influence (Maria Stock et al., 2017; Yang & Shafi, 2020) or negative consequences (Liu et al., 2022; Najafi-Tavani et al., 2022). Moreover, inconsistencies exist regarding whether CP improves product or process innovation outcomes (Anning-Dorson, 2018). Therefore, it is essential to develop a more nuanced understanding of the mechanisms through which CP affects SME innovation performance.

Following Najafi-Tavani et al. (2022), this study defines CP as the degree to which customers are engaged in product and process development, consistent with the knowledge collaboration view (Wang & Hu, 2020). Research has shown that extensive CP can facilitate the acquisition of the knowledge needed for a firm's innovation activities (Yang & Shafi, 2020). In product innovation, engaging multiple customer partners results in a broader range of information being made available, thus allowing SMEs to better understand and address customer needs (Yuk & Garrett, 2023). In process innovation, CP can shorten the time to market and enable the generation of new ideas and solutions (Delpechitre et al., 2018). Despite the potential benefits, CP as a source of new knowledge does not always lead to successful innovation outcomes. For instance, Liu et al. (2022) find that CP introduces complexities that can hinder performance. Similarly, Wang (2022) emphasizes that the effectiveness of CP depends heavily on how well firms can absorb and transform the knowledge gained from customers.

The inconsistent results have prompted research into certain mechanisms and the circumstances under which firms, including SMEs, can profit more from CP. Lu et al. (2021) suggest that the breadth and depth of collaboration are significantly associated with SMEs’ innovation performance, indicating that the effectiveness of CP may be limited. The tacit nature of knowledge means firms often struggle to absorb customer insights effectively, making it challenging to translate these insights into practical understanding (Zhang et al., 2024). Additionally, as knowledge is mainly created through the process of collaboration, firms may find it difficult to utilize knowledge without fully absorbing it first (Aliasghar et al., 2023). Further research on the nuanced effects of CP is required to shed light on its limitations in capturing customer insights and promoting innovation performance.

Supplier participation in innovationThe influence of SP on innovation has yielded inconsistent findings. Some studies have demonstrated positive impacts (Li, 2023; Yang & Shafi, 2020), while others have found no significant or negative effects (Cruz-González et al., 2015; Jean et al., 2014). Therefore, a more nuanced understanding of the mechanism through which SP influences both types of innovation performance of SMEs is required.

SP is defined as the active engagement of suppliers in various processes of the firm, especially activities related to product development, innovation, and quality improvement (Cheng & Krumwiede, 2018). Studies have shown that through SP, firms can use the technical knowledge and skills of suppliers to generate ideas, check for manufacturability, and solve problems quickly (Oh & In, 2023). For product innovation, integrating suppliers in the development of innovation frequently results in improved technological approaches, which enables firms to introduce superior products that offer a competitive edge in terms of quality and cost (Li, 2023). Suppliers’ extensive suggestions and perspectives can enhance innovation performance (Kazemargi et al., 2022). For SMEs, SP can lead to a better understanding of the technical requirements corresponding with market trends (Li, 2023). For process innovation, SP focuses on improving manufacturing and operational processes, which could help firms increase production efficiency, cut expenses, and improve overall quality of their processes. This collaboration results in valuable operational efficiencies, which are essential for preserving competitive edge (Oh & In, 2023). However, SP has potential drawbacks, such as knowledge leakage and slower decision-making processes (Wang et al., 2022). These issues can hinder the overall success of both product and process innovation efforts.

In conclusion, a better understanding of how CP and SP boost innovation performance could be gained by examining how the information gained from CP and SP is integrated into a more thorough grasp of the market, and how expertise and knowledge from customers and suppliers are absorbed, transformed, and applied in the development process to drive innovation.

Absorptive capacityAs described above, customer or supplier input is often raw and unstructured and must be processed and integrated into the firm's existing knowledge base. The firm's ability to do this—its absorptive capacity—is critical for transforming that information into valuable outcomes, as supported by Zahra and George's (2002) theory of absorptive capacity. However, how knowledge from customers and suppliers is integrated into product development is underexplored (Storey & Larbig, 2018). The capacity for knowledge collaboration is linked to the intensity of efforts to acquire new external knowledge (Audretsch et al., 2023). Absorptive capacity, one important dimension of knowledge collaboration, involves acquiring, embracing, altering, and integrating customer or supplier knowledge to meet a firm's goals (Albats et al., 2023; Tang et al., 2020). Absorptive capacity is the ability to comprehend, integrate, and utilize external knowledge (Roberts et al., 2012). It is essential for new product development, as it internalizes customer needs and technological issues, enhancing understanding and creating product advantages (Storey & Larbig, 2018). Supplier knowledge addresses technical gaps, improving understanding of innovative technologies and product value (Oh & In, 2023).

A deep comprehension of the mechanisms of customer and supplier knowledge is critical for aligning products with market expectations and ensuring efficient, cost-effective innovation. Such activities augment or modify the firm's preconceived perceptions of innovative technologies and how new products/processes generate value (Najafi-Tavani et al., 2013). Firms must absorb and transform knowledge of commercial implementations, optimizing innovation performance and value chains (Solaimani & Van Der Veen, 2022). Despite these insights, the role of absorptive capacity in translating customer and supplier knowledge into successful SME innovation remains limited.

Business environmentUnder what conditions absorptive capacity will function more effectively is a question of high importance. The business environment comprises external associations, factors, and surroundings that influence business outcomes—a healthy business environment promotes sustainable economic development and plays an important role in the effect of absorptive capacity on innovation performance of SMEs (Yin et al., 2023).

A firm's capacities or strategies must align with the features of its environment to achieve a competitive advantage (Arend et al., 2017). The KBV also indicates that the features of industries and markets in which the firm exists influence the effectiveness of its capacities (Phelps et al., 2012). Some studies have examined the relationship between the business environment and innovation capabilities. For instance, Mata et al. (2023) find that absorptive capacity can have diverse impacts on innovation performance in different types of intellectual capital environments. Scholars also argue that a healthy business environment can enhance innovation capabilities by fostering fair competitive markets and encouraging firms to invest in R&D, collaborate on new technologies, and adopt innovative practices (Liu & Atuahene-Gima, 2018; Tidd & Bessant, 2020). Despite these studies, little is known about how the business environment influences the effectiveness of a firm's absorptive capacity on innovation performance. This issue is worth considering because the relationship between collaborative capability and innovation performance could differ depending on the business environment (Aloini et al., 2015). Chinese society is deeply influenced by guanxi, and when competition in a city is fair, there is a reduced likelihood that informal practices such as guanxi would significantly affect business operations, which would lead to a healthier business environment (Liu et al., 2023). Therefore, central to a healthy business environment is competitive fairness, which refers to the level of equity and impartiality in competitive environments where firms operate (Graef et al., 2018). A fair environment ensures all firms have equal rights, equal opportunities, and equal rules in market economic activities (Zhang et al., 2020); thus, this study focuses on competitive fairness to characterize the business environment.

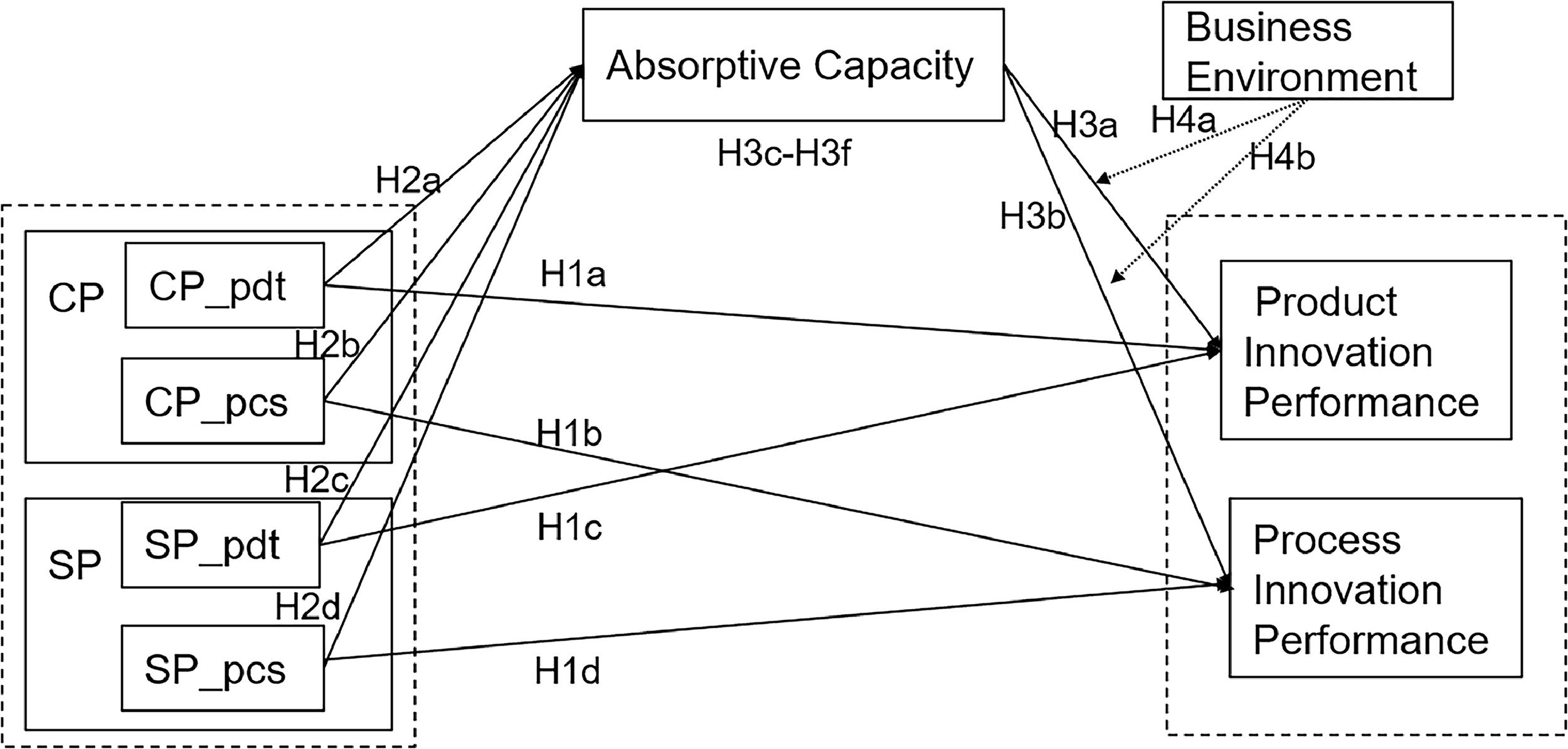

Conceptual modelThis study's conceptual framework is illustrated in Fig. 1. During the innovation process, tapping into customer and supplier knowledge through CP and SP is a critical requirement for the assimilation and transformation of new market and technological insights. The framework underscores the significance of absorptive capacity as an important mechanism for accessing, transforming, and integrating novel knowledge, thereby fostering innovation and aiding in the attainment of organizational objectives (Tang et al., 2020). Furthermore, absorptive capacity is proposed to play a mediating role in how collaboration with customer and supplier knowledge, particularly through CP in product innovation (CP_pdt), CP in process innovation (CP_pcs), SP in product innovation (SP_pdt), and SP in process innovation (SP_pcs), influences the performance of product and process innovation. Additionally, the business environment factor of competitive fairness acts as a moderator, influencing the effectiveness of absorptive capacity in enhancing the success of knowledge collaboration in both product and process innovation.

Customer participation in innovation of SMEsThis study outlines that innovation in SMEs often encounters limitations due to financial and resource constraints. Engaging customers can mitigate these limitations and enhance the likelihood of successful innovation. Through close customer interactions, SMEs can gain diverse knowledge (Scuotto et al., 2017), an important resource for bridging innovation knowledge gaps, enriching knowledge variety, and fostering new product ideas. Effective CP also deepens the firm's insights into customer requirements, providing products that align more closely with market needs, thereby increasing market acceptance and innovation performance, beyond what could be achieved without customer knowledge input (Chaithanapat & Rakthin, 2021).

In the context of SMEs, innovation performance is linked to how such firms utilize product innovation to gain a competitive advantage (Scuotto et al., 2017). Given their dynamic nature and resource limitations, SMEs increasingly value external contributions to their innovation processes. Thus, integrating CP into these processes is a strategic necessity, transforming new and existing knowledge into innovative products. This collaborative model, grounded in the KBV, enables SMEs to adapt their offerings to real market needs (Brunswicker & Vanhaverbeke, 2015). Notably, customer input often introduces unique ideas, extending the traditional boundaries of innovation for SMEs.

Moreover, CP in innovation provides SMEs with practical insights into product use in real-life scenarios. This understanding is vital for SMEs to accurately identify customer needs, avoid developing unnecessary features, and achieve superior innovation performance (Chaithanapat & Rakthin, 2021). Recognizing that product and process innovation are distinct, with different mechanisms of success (Hall et al., 2009), this study differentiates between two innovation types. Addressing the gap in previous research, this study examines the impact of CP on both product and process innovation performance. Therefore, this study proposes the following:

H1a-b

CP in product innovation (H1a)/CP in process innovation (H1b) positively influences SME product innovation performance.

Supplier participation in innovation of SMEsIn addition to the customer, the supplier is another partner in the supply chain that can participate in SMEs’ innovation. Similar to CP, stable relationships with suppliers allow SMEs to gain heterogeneous knowledge (Thomas, 2013), offering a rich reservoir of insights or technologies that could bridge the knowledge gap for innovation and help these firms deepen their understanding of technology and generate pioneering product or process ideas. Effective SP aligns supplier offerings with the firm's actual needs, leading to better market-aligned products and processes and enhanced innovation outcomes (Cheng & Sheu, 2022). Therefore, like CP, SP is also increasingly recognized as an indispensable strategy for SMEs to boost innovation performance.

Innovation performance with SP is measured by how effectively the firm taps into supplier-driven innovation to strengthen market competitiveness. Emphasizing SP in the innovation cycle becomes essential because of the financial and resource limitations of SMEs, which transforms collaborative insights and specialized supplier knowledge into innovative products and processes. Such a cooperative approach, rooted in resource-based theory and the KBV like CP, enables SMEs to create solutions that meet actual technical and market requirements (Wang & Hu, 2020).

In addition, the active involvement of suppliers in the innovation process provides SMEs with a vital comprehensive understanding of how their technology or materials are used throughout the product lifecycle (Delgado-Verde & Díez-Vial, 2023), which is important for SMEs to refine product specifications, avoid unnecessary technical development, and achieve optimal innovation performance (Kang & Um, 2023). Thus, this study proposes the following:

H1c-d

SP in product innovation (H1a)/SP in process innovation (H1b) positively influences SME product innovation performance.

Customer participation and absorptive capacityCui and Wu (2016) emphasize that consumer knowledge benefits the innovation process only when it is effectively diffused between customers and the firm. Absorptive capacity, defined as the firm's ability to organize, process, and meaningfully integrate new knowledge (Tang et al., 2020), plays an important role in this process. The assimilation and transformation of customer knowledge refine SME's existing perceptions of customer needs, enhancing the collaboration with customers (Zhao et al., 2021). CP significantly increases the likelihood of assimilating and transforming customer knowledge (Flor et al., 2018), key dimensions of absorptive capacity, and thus facilitate a firm's absorptive capacity. CP provides deeper insights into customer behaviors and preferences, enhancing both the depth and breadth of acquired knowledge (Mahr et al., 2014). This facilitates a more nuanced comprehension of customer needs, thus decreasing uncertainty and strengthening absorptive capacity, driving better innovation outcomes (Obal et al., 2024). As CP includes CP in product and process innovation, this study proposes the following:

H2a-b

CP in product innovation (H2a)/CP in process innovation (H2b) positively impacts absorptive capacity.

Supplier participation and absorptive capacityNajafi-Tavani et al. (2013) underscores the importance of transforming supplier knowledge through absorptive capacity. This process enhances innovation by enabling project teams to integrate insights regarding material properties, technologies, or specific components learned from suppliers, which can greatly influence the innovation path. SP enhances supplier knowledge assimilation and internalization (Flor et al., 2018), thereby increasing the firm's absorptive capacity. Proactive SP reveals essential specifications, advanced techniques, driving product and process development (Inauen & Schenker‐Wicki, 2011). SP helps extract nuanced insights and critical technological details, aiding project teams in understanding complex technologies (Wang et al., 2023). Increased supplier knowledge leads to better collaboration outcomes, including cost, quality, and market share improvements (Johnsen, 2009). High SP levels mitigate uncertainties and misinterpretations, enriching the understanding of suppliers’ implicit technical insights. Hence, this study proposes the following:

H2c-d

SP in product innovation (H2c)/SP in process innovation (H2d) positively impacts on absorptive capacity.

Absorptive capacity and product and process innovation performanceEffective absorption of a supply chain partner's knowledge is often linked to innovation performance (Cohen & Levinthal, 1990; Malhotra et al., 2005). For customer needs, focusing solely on explicit needs limits the potential for discovering opportunities for value creation. Rather, it is vital to recognize and meet customers’ unexpressed, latent needs (Cui & Wu, 2016). Additionally, integrating supplier knowledge into the innovation process introduces another dimension to understanding market demands. Suppliers, with their specialized knowledge of materials, technologies, and processes, can offer insights beyond the immediate customer needs (Menguc et al., 2014), which will not only enhance product features but also optimize production processes, cut costs, and improve overall efficiency. A deep understanding of both customer and supplier perspectives can lead to innovative, cost-effective products and processes, empowering firms’ competitive advantage in dynamic markets (Kim et al., 2023).

While customer or supplier knowledge absorptive capacity influences the firm's product development process through knowledge assimilation and transformation (Najafi-Tavani et al., 2013), it is also necessary to ensure that a new product can be designed into a successful business. Identifying what creates value for customers and how they will eventually perceive and utilize a product or service (Ferreras-Méndez et al., 2015) gives rise to enhanced interactions that would enhance innovation performance. During product development, a high level of absorptive capacity regarding customer and supplier knowledge may also help recognize extra applications and benefits, diminish unnecessary use and drawbacks, and enable the co-creation of value (Coviello & Joseph, 2012). By effectively integrating customer and supplier knowledge into the product development process, firms–particularly SMEs–can access valuable insights and feedback, thereby driving continuous improvements and innovation in their product and process offerings. Therefore, this study proposes the following:

H3a-b

Absorptive capacity has a positive impact on SME product innovation performance (H3a)/process innovation performance (H3b).

H3c–H3f

Absorptive capacity has a mediating effect between CP_pdt/SP_pdt/CP_pcs/SP_pcs and innovation performance.

Moderating role of business environment between absorptive capacity and innovation performanceThe environmental context in which a firm operates significantly influences the effect of absorptive capacity on innovation performance. This is because organizational effectiveness and innovation outcomes result from fitting the characteristics of the firm, such as its structure, strategic strategies, and decision-making processes, to the demands of the business environment (Naveed et al., 2022). The business environment serves as a contextual conditions under which firms can enhance their absorptive capacity better, enabling them to recognize, assimilate, and apply external knowledge from customers/suppliers more effectively (Liu et al., 2021; Tsai & Yang, 2013). New product development is a complicated and factually ambiguous process that requires a healthy business environment to ensure the protection of intellectual property. A healthy business environment fosters innovation performance (Le & Do, 2024). By contrast, an unhealthy environment results in limited innovation performance. Certain areas in China remain in a transitional phase with weak economic systems. SMEs often seek rent and corruption to enhance their absorptive capacity through government R&D subsidies, undermining a fair business environment. The business environment affects the relationship between absorptive capacity and innovation performance in two ways. First, optimizing the environment reduces unfair competitive practices, allowing firms to fully utilize their absorptive capacity, believing that their innovations will be protected and rewarded (Huang, 2011). Second, a healthy business environment may streamline administrative procedures, expediting patent and product approvals, thus leading to a more effective application of knowledge gained through high absorptive capacity. Hence, this study proposes the following:

H4

The business environment moderates the impact of absorptive capacity on product innovation performance (H4a)/process innovation performance (H4b).

MethodologyData sourceThe main data source for the following sections is the Enterprises Survey on Innovation and Entrepreneurship of China (ESIEC) project of Peking University. This project involves conducting a field survey of private enterprises in China, offering academic research with extensive data and relevant platforms (Zhang, 2018). The ESIEC project initiated its first round of benchmark surveys in 2018. From July to August 2018, the ESIEC targeted privately owned and foreign-funded enterprises registered between 2010 and 2017 in China, as well as their founders. The baseline survey was carried out across six provinces: Liaoning, Shanghai, Zhejiang, Henan, Guangdong, and Gansu. Previous studies in this research area used similar datasets (e.g., Knudsen, 2007; Yin et al., 2023).

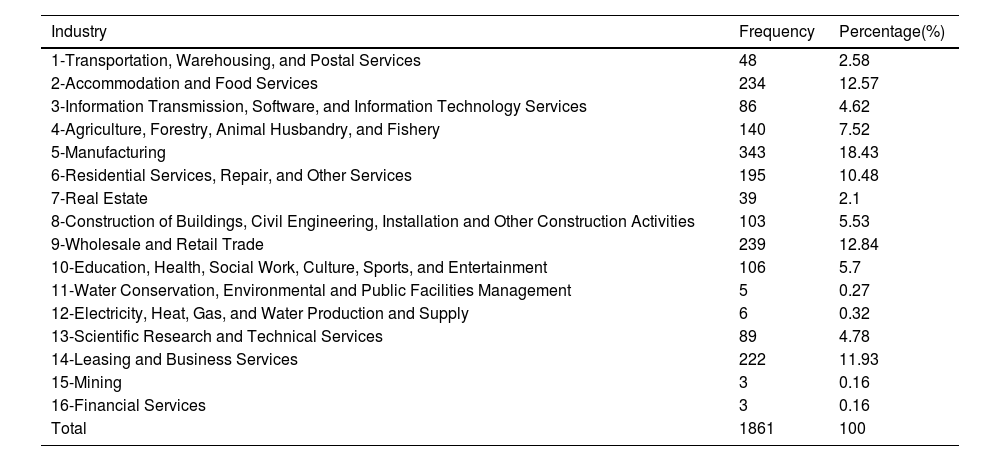

The dataset comprises 6198 firm-level observations across diverse industries, providing information on firm size, innovation activities, collaboration efforts, R&D expenditure, and innovation outcomes related to both products and processes. Additionally, it contains firm-level details such as age, location, annual sales, and other relevant data. Prior to carrying out the empirical analysis, data cleaning was performed. This study, primarily focused on SMEs that are continuously operational, followed the suggestions of Chundakkadan and Sasidharan (2023) by excluding firms with abnormal employee numbers or annual sales outliers. Observations with missing values for essential variables were also removed. Considering the varied definitions of SMEs and the specific context of China, this research aligns with Audretsch et al. (2023) and Santoro et al. (2018), defining SMEs as firms with fewer than 250 full-time employees, thereby excluding larger firms. To examine the effects of the business environment on these firms, the comprehensive city-level business environment dataset compiled by Peking University was utilized. The final analysis included 1861 SMEs from 16 industries, as detailed in Table 1. To mitigate outliers’ influence, all continuous variables were winsorized at the 1% and 99% thresholds.

Industrial distribution.

| Industry | Frequency | Percentage(%) |

|---|---|---|

| 1-Transportation, Warehousing, and Postal Services | 48 | 2.58 |

| 2-Accommodation and Food Services | 234 | 12.57 |

| 3-Information Transmission, Software, and Information Technology Services | 86 | 4.62 |

| 4-Agriculture, Forestry, Animal Husbandry, and Fishery | 140 | 7.52 |

| 5-Manufacturing | 343 | 18.43 |

| 6-Residential Services, Repair, and Other Services | 195 | 10.48 |

| 7-Real Estate | 39 | 2.1 |

| 8-Construction of Buildings, Civil Engineering, Installation and Other Construction Activities | 103 | 5.53 |

| 9-Wholesale and Retail Trade | 239 | 12.84 |

| 10-Education, Health, Social Work, Culture, Sports, and Entertainment | 106 | 5.7 |

| 11-Water Conservation, Environmental and Public Facilities Management | 5 | 0.27 |

| 12-Electricity, Heat, Gas, and Water Production and Supply | 6 | 0.32 |

| 13-Scientific Research and Technical Services | 89 | 4.78 |

| 14-Leasing and Business Services | 222 | 11.93 |

| 15-Mining | 3 | 0.16 |

| 16-Financial Services | 3 | 0.16 |

| Total | 1861 | 100 |

Product innovation performance. Product innovation performance assesses the returns of resource and investment input in innovation. This study used the sales share of new products or services to measure product innovation performance, which is an effective metric of collaboration and innovation performance (Audretsch et al., 2023; Belitski & Rejeb, 2022; Berchicci, 2013; van Beers & Zand, 2014).

Process innovation performance. Process innovations are new or significantly improved procedures, even if they are not necessarily brand-new for the industry. According to Rammer (2023), process innovation performance is measured from two main aspects, cost efficiency and quality improvement, which have also been adopted in other studies (Ashok et al., 2016). Following the methods of Si et al. (2020) and Ozdemir et al. (2023), this study set two dummy variables: costreduce is set to 1 if the process innovation introduced by the firm last year reduced the average cost, and 0 otherwise; qualityenhance is assigned 1 if the process innovation introduced by the firm last year led to improvements in the quality of products or services, and 0 otherwise.

Independent variablesIn this study, binary variables were employed to assess the presence of collaborative innovation with customers and suppliers, which equals 1 if the firm collaborates with customers/suppliers in product/process innovation activities, and 0 otherwise (Belitski & Rejeb, 2022). Four key concepts are considered: Customer Participation in Product Innovation (CP_pdt), Customer Participation in Process Innovation (CP_pcs), Supplier Participation in Product Innovation (SP_pdt), and Supplier Participation in Process Innovation (SP_pcs).

Mediating variableTo measure the absorptive capacity, this research used R&D intensity, calculated as “innovation expenditure/sales” (Cohen & Levinthal, 1990; Tsai, 2001), which is widely applied in other studies (Lyu et al., 2023; Tang et al., 2020; Van Beers & Zand, 2014). To minimize skewness, the logarithmic transformation of this variable was employed.

Moderate and control variablesAs previously mentioned, fair competition is vital for the business environment to remain healthy. Thus the moderating variable business environment is characterized by competitive fairness, which reflects the fairness of competition in the city where the firm is registered (Suttle, 2022). The business environment dataset conducted by Peking University (Zhang et al., 2023) was used.

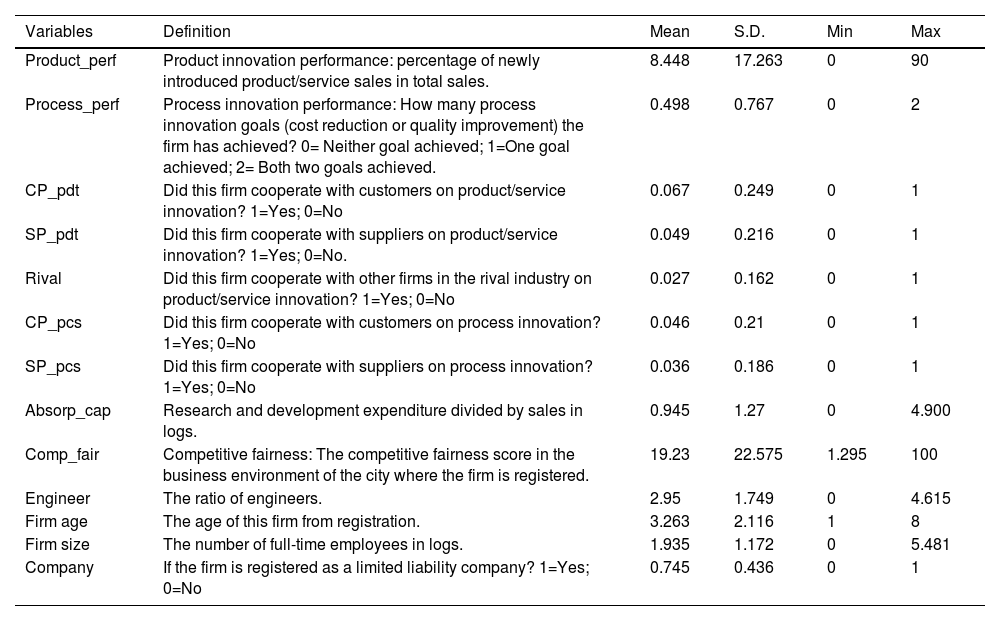

Drawing on the work of Belitski et al. (2024), Naveed et al. (2022), and Yin et al. (2023), several control variables that might impact innovation performance were included. Rival controls for the effect of collaboration with competitors on fostering innovation. It is coded as 1 for firms collaborating with rivals in product or process innovation activities, and 0 otherwise. Engineer refers to the ratio of engineers, representing the firm's technical expertise. Firm age is calculated by the number of operational years to reflect potential declining marginal profits over time. Firm size is measured by the number of full-time employees and logged to reduce innovation bias resulting from firms’ scale, following common practice in studies of firm dynamics. To account for fixed effects within and across industries, 16 industry dummies are introduced, though the detailed results are suppressed to save space. Additionally, 6 region-province fixed effects are included to control location-based differences. A complete list of these variables is depicted in Table 2.

Variable definition and descriptive statistics.

| Variables | Definition | Mean | S.D. | Min | Max |

|---|---|---|---|---|---|

| Product_perf | Product innovation performance: percentage of newly introduced product/service sales in total sales. | 8.448 | 17.263 | 0 | 90 |

| Process_perf | Process innovation performance: How many process innovation goals (cost reduction or quality improvement) the firm has achieved? 0= Neither goal achieved; 1=One goal achieved; 2= Both two goals achieved. | 0.498 | 0.767 | 0 | 2 |

| CP_pdt | Did this firm cooperate with customers on product/service innovation? 1=Yes; 0=No | 0.067 | 0.249 | 0 | 1 |

| SP_pdt | Did this firm cooperate with suppliers on product/service innovation? 1=Yes; 0=No. | 0.049 | 0.216 | 0 | 1 |

| Rival | Did this firm cooperate with other firms in the rival industry on product/service innovation? 1=Yes; 0=No | 0.027 | 0.162 | 0 | 1 |

| CP_pcs | Did this firm cooperate with customers on process innovation? 1=Yes; 0=No | 0.046 | 0.21 | 0 | 1 |

| SP_pcs | Did this firm cooperate with suppliers on process innovation? 1=Yes; 0=No | 0.036 | 0.186 | 0 | 1 |

| Absorp_cap | Research and development expenditure divided by sales in logs. | 0.945 | 1.27 | 0 | 4.900 |

| Comp_fair | Competitive fairness: The competitive fairness score in the business environment of the city where the firm is registered. | 19.23 | 22.575 | 1.295 | 100 |

| Engineer | The ratio of engineers. | 2.95 | 1.749 | 0 | 4.615 |

| Firm age | The age of this firm from registration. | 3.263 | 2.116 | 1 | 8 |

| Firm size | The number of full-time employees in logs. | 1.935 | 1.172 | 0 | 5.481 |

| Company | If the firm is registered as a limited liability company? 1=Yes; 0=No | 0.745 | 0.436 | 0 | 1 |

Note: Number of firms: 1861 after removing missing values of the variables. Absorp_cap: Absorptive capacity. Comp_fair: Competitive fairness.

This study examined left-censored data using the Tobit regression model recommended by Wooldridge (2010), which has been utilized in numerous studies about firm innovation (Van Beers & Zand, 2014; Yin et al., 2023). Tobit regression was chosen due to the unique distribution of the first-stage dependent variable, product innovation performance, and the second-stage dependent variable absorptive capacity, both of which exhibit many zero-value observations. Tobit regression provides more accurate estimations by accounting for the censoring in the dependent variable than traditional linear regression.

Ordered logistic regressionOrdered Logistic Regression (OLR) is a statistical method used to predict outcomes for ordinal dependent variables. The model estimates the odds of an observation falling into a higher-ordered category based on various predictor variables (Gelman & Hill, 2006). As the variable Process_perf is inherently ordinal, with three distinct categories: 0, 1, and 2, employing ordered logistic regression is appropriate.

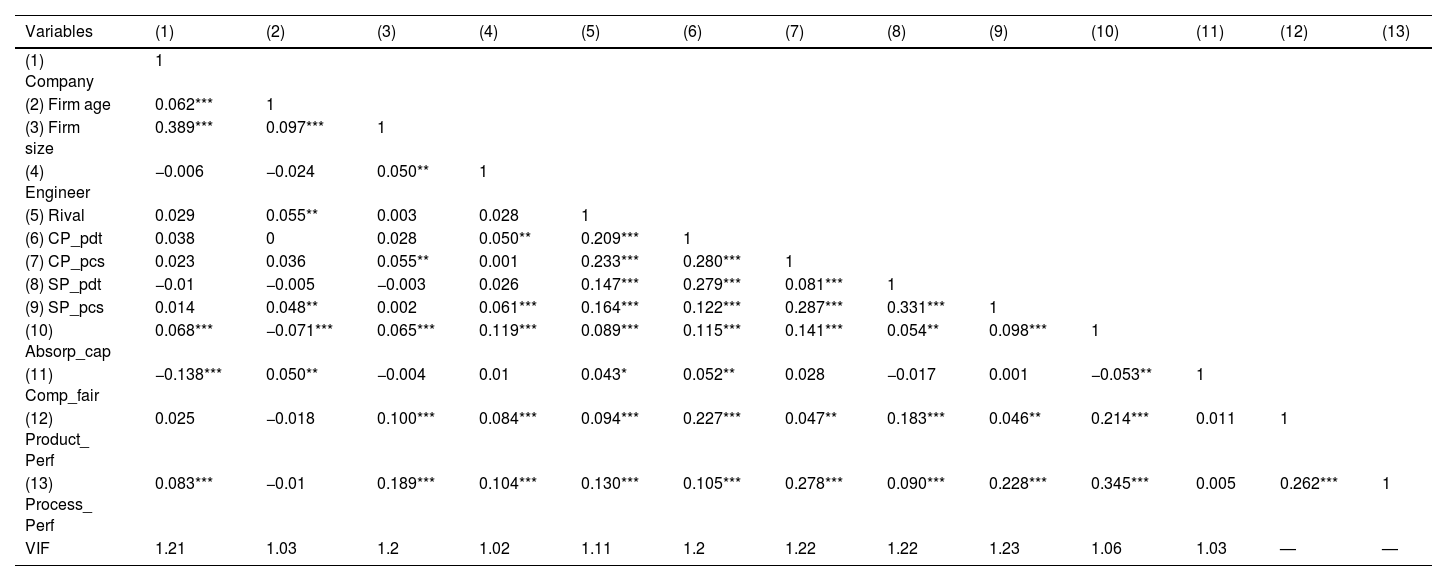

ResultsThe descriptive statistics of the variables are displayed in Table 2, where the mean values of Product_perf and Process_perf are 8.448 and 0.498, respectively, which are consistent with the results reported by Audretsch et al. (2023). The mean absorptive capacity has a value of 0.945, with a standard deviation of 1.27. Moreover, all variable correlations are shown in Table 3, which demonstrates that both CP and SP have a positive impact on absorptive capacity, and product and process innovation performance. Moreover, multicollinearity is not an issue, as the variance inflation factor (VIF) analysis reveals that all variables have VIF values less than 1.5, which is far less than the recommended threshold of 10.

Pearson of correlation and VIF.

| Variables | (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) | (11) | (12) | (13) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (1) Company | 1 | ||||||||||||

| (2) Firm age | 0.062*** | 1 | |||||||||||

| (3) Firm size | 0.389*** | 0.097*** | 1 | ||||||||||

| (4) Engineer | −0.006 | −0.024 | 0.050** | 1 | |||||||||

| (5) Rival | 0.029 | 0.055** | 0.003 | 0.028 | 1 | ||||||||

| (6) CP_pdt | 0.038 | 0 | 0.028 | 0.050** | 0.209*** | 1 | |||||||

| (7) CP_pcs | 0.023 | 0.036 | 0.055** | 0.001 | 0.233*** | 0.280*** | 1 | ||||||

| (8) SP_pdt | −0.01 | −0.005 | −0.003 | 0.026 | 0.147*** | 0.279*** | 0.081*** | 1 | |||||

| (9) SP_pcs | 0.014 | 0.048** | 0.002 | 0.061*** | 0.164*** | 0.122*** | 0.287*** | 0.331*** | 1 | ||||

| (10) Absorp_cap | 0.068*** | −0.071*** | 0.065*** | 0.119*** | 0.089*** | 0.115*** | 0.141*** | 0.054** | 0.098*** | 1 | |||

| (11) Comp_fair | −0.138*** | 0.050** | −0.004 | 0.01 | 0.043* | 0.052** | 0.028 | −0.017 | 0.001 | −0.053** | 1 | ||

| (12) Product_ Perf | 0.025 | −0.018 | 0.100*** | 0.084*** | 0.094*** | 0.227*** | 0.047** | 0.183*** | 0.046** | 0.214*** | 0.011 | 1 | |

| (13) Process_ Perf | 0.083*** | −0.01 | 0.189*** | 0.104*** | 0.130*** | 0.105*** | 0.278*** | 0.090*** | 0.228*** | 0.345*** | 0.005 | 0.262*** | 1 |

| VIF | 1.21 | 1.03 | 1.2 | 1.02 | 1.11 | 1.2 | 1.22 | 1.22 | 1.23 | 1.06 | 1.03 | — | — |

Note: *** p < 0.01, ** p < 0.05, * p < 0.1.

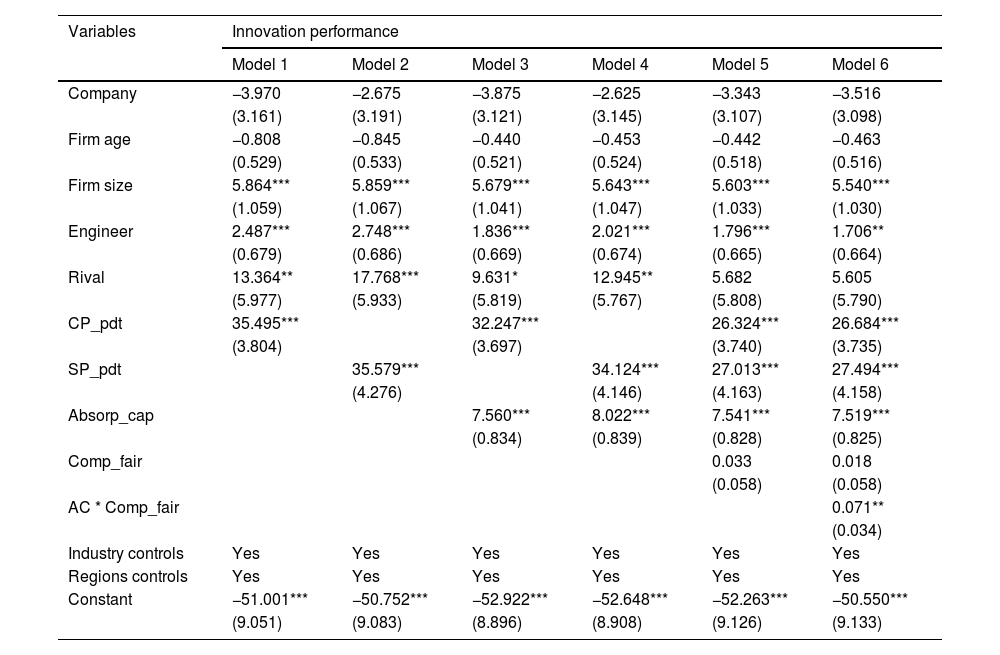

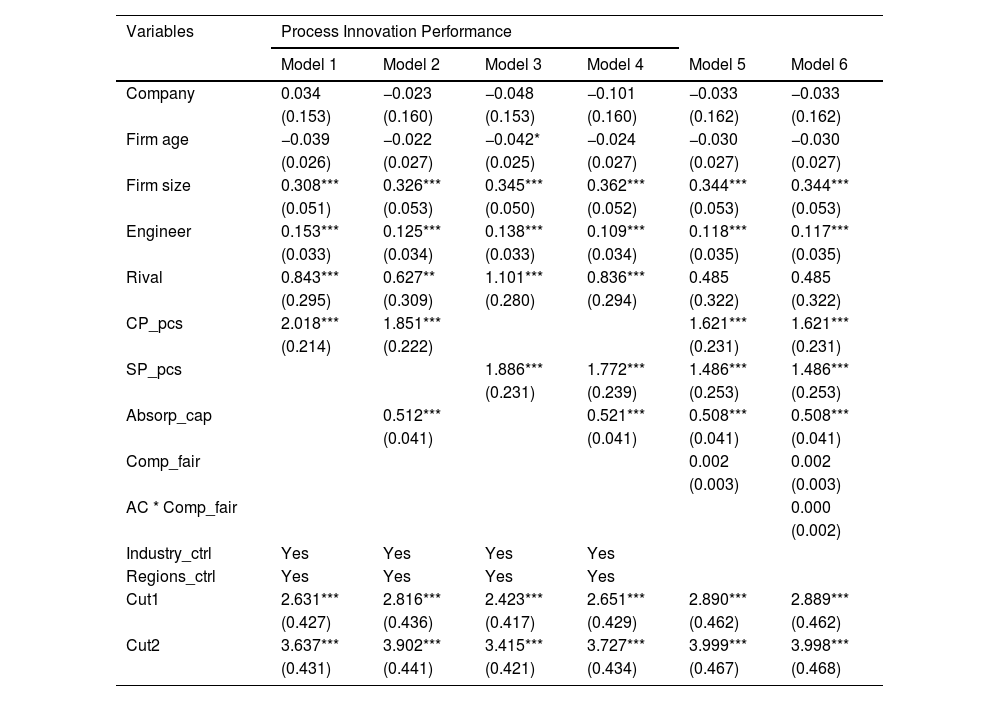

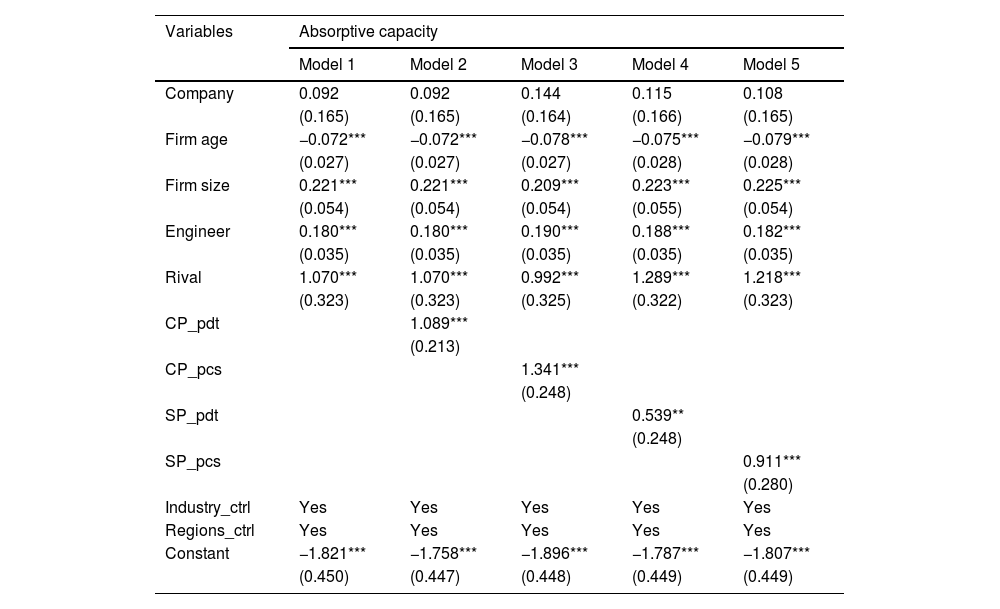

The direct effects of customer and supplier participation in product (Tobit regression results) and process innovation (ordered logistic regression results) are displayed in Tables 4 and 5, with brackets including standard errors. The main effects of customer/supplier participation are added hierarchically in the models. Table 6 presents the direct effects of CP/SP on absorptive capacity.

Hierarchical multiple regression results of direct effect, mediating effect, and moderating effect-1.

| Variables | Innovation performance | |||||

|---|---|---|---|---|---|---|

| Model 1 | Model 2 | Model 3 | Model 4 | Model 5 | Model 6 | |

| Company | −3.970 | −2.675 | −3.875 | −2.625 | −3.343 | −3.516 |

| (3.161) | (3.191) | (3.121) | (3.145) | (3.107) | (3.098) | |

| Firm age | −0.808 | −0.845 | −0.440 | −0.453 | −0.442 | −0.463 |

| (0.529) | (0.533) | (0.521) | (0.524) | (0.518) | (0.516) | |

| Firm size | 5.864*** | 5.859*** | 5.679*** | 5.643*** | 5.603*** | 5.540*** |

| (1.059) | (1.067) | (1.041) | (1.047) | (1.033) | (1.030) | |

| Engineer | 2.487*** | 2.748*** | 1.836*** | 2.021*** | 1.796*** | 1.706** |

| (0.679) | (0.686) | (0.669) | (0.674) | (0.665) | (0.664) | |

| Rival | 13.364** | 17.768*** | 9.631* | 12.945** | 5.682 | 5.605 |

| (5.977) | (5.933) | (5.819) | (5.767) | (5.808) | (5.790) | |

| CP_pdt | 35.495*** | 32.247*** | 26.324*** | 26.684*** | ||

| (3.804) | (3.697) | (3.740) | (3.735) | |||

| SP_pdt | 35.579*** | 34.124*** | 27.013*** | 27.494*** | ||

| (4.276) | (4.146) | (4.163) | (4.158) | |||

| Absorp_cap | 7.560*** | 8.022*** | 7.541*** | 7.519*** | ||

| (0.834) | (0.839) | (0.828) | (0.825) | |||

| Comp_fair | 0.033 | 0.018 | ||||

| (0.058) | (0.058) | |||||

| AC * Comp_fair | 0.071** | |||||

| (0.034) | ||||||

| Industry controls | Yes | Yes | Yes | Yes | Yes | Yes |

| Regions controls | Yes | Yes | Yes | Yes | Yes | Yes |

| Constant | −51.001*** | −50.752*** | −52.922*** | −52.648*** | −52.263*** | −50.550*** |

| (9.051) | (9.083) | (8.896) | (8.908) | (9.126) | (9.133) | |

Note: *** p < 0.01, ** p < 0.05, * p < 0.1.

Hierarchical multiple regression results of direct effect, mediating effect, and moderating effect-2.

| Variables | Process Innovation Performance | |||||

|---|---|---|---|---|---|---|

| Model 1 | Model 2 | Model 3 | Model 4 | Model 5 | Model 6 | |

| Company | 0.034 | −0.023 | −0.048 | −0.101 | −0.033 | −0.033 |

| (0.153) | (0.160) | (0.153) | (0.160) | (0.162) | (0.162) | |

| Firm age | −0.039 | −0.022 | −0.042* | −0.024 | −0.030 | −0.030 |

| (0.026) | (0.027) | (0.025) | (0.027) | (0.027) | (0.027) | |

| Firm size | 0.308*** | 0.326*** | 0.345*** | 0.362*** | 0.344*** | 0.344*** |

| (0.051) | (0.053) | (0.050) | (0.052) | (0.053) | (0.053) | |

| Engineer | 0.153*** | 0.125*** | 0.138*** | 0.109*** | 0.118*** | 0.117*** |

| (0.033) | (0.034) | (0.033) | (0.034) | (0.035) | (0.035) | |

| Rival | 0.843*** | 0.627** | 1.101*** | 0.836*** | 0.485 | 0.485 |

| (0.295) | (0.309) | (0.280) | (0.294) | (0.322) | (0.322) | |

| CP_pcs | 2.018*** | 1.851*** | 1.621*** | 1.621*** | ||

| (0.214) | (0.222) | (0.231) | (0.231) | |||

| SP_pcs | 1.886*** | 1.772*** | 1.486*** | 1.486*** | ||

| (0.231) | (0.239) | (0.253) | (0.253) | |||

| Absorp_cap | 0.512*** | 0.521*** | 0.508*** | 0.508*** | ||

| (0.041) | (0.041) | (0.041) | (0.041) | |||

| Comp_fair | 0.002 | 0.002 | ||||

| (0.003) | (0.003) | |||||

| AC * Comp_fair | 0.000 | |||||

| (0.002) | ||||||

| Industry_ctrl | Yes | Yes | Yes | Yes | ||

| Regions_ctrl | Yes | Yes | Yes | Yes | ||

| Cut1 | 2.631*** | 2.816*** | 2.423*** | 2.651*** | 2.890*** | 2.889*** |

| (0.427) | (0.436) | (0.417) | (0.429) | (0.462) | (0.462) | |

| Cut2 | 3.637*** | 3.902*** | 3.415*** | 3.727*** | 3.999*** | 3.998*** |

| (0.431) | (0.441) | (0.421) | (0.434) | (0.467) | (0.468) | |

Note: *** p < 0.01, ** p < 0.05, * p < 0.1.

Direct effects on absorptive capacity.

| Variables | Absorptive capacity | ||||

|---|---|---|---|---|---|

| Model 1 | Model 2 | Model 3 | Model 4 | Model 5 | |

| Company | 0.092 | 0.092 | 0.144 | 0.115 | 0.108 |

| (0.165) | (0.165) | (0.164) | (0.166) | (0.165) | |

| Firm age | −0.072*** | −0.072*** | −0.078*** | −0.075*** | −0.079*** |

| (0.027) | (0.027) | (0.027) | (0.028) | (0.028) | |

| Firm size | 0.221*** | 0.221*** | 0.209*** | 0.223*** | 0.225*** |

| (0.054) | (0.054) | (0.054) | (0.055) | (0.054) | |

| Engineer | 0.180*** | 0.180*** | 0.190*** | 0.188*** | 0.182*** |

| (0.035) | (0.035) | (0.035) | (0.035) | (0.035) | |

| Rival | 1.070*** | 1.070*** | 0.992*** | 1.289*** | 1.218*** |

| (0.323) | (0.323) | (0.325) | (0.322) | (0.323) | |

| CP_pdt | 1.089*** | ||||

| (0.213) | |||||

| CP_pcs | 1.341*** | ||||

| (0.248) | |||||

| SP_pdt | 0.539** | ||||

| (0.248) | |||||

| SP_pcs | 0.911*** | ||||

| (0.280) | |||||

| Industry_ctrl | Yes | Yes | Yes | Yes | Yes |

| Regions_ctrl | Yes | Yes | Yes | Yes | Yes |

| Constant | −1.821*** | −1.758*** | −1.896*** | −1.787*** | −1.807*** |

| (0.450) | (0.447) | (0.448) | (0.449) | (0.449) | |

Note: Standard errors in parentheses; *** p < 0.01, ** p < 0.05, * p < 0.1; Observations:1861.

Tables 4 and 5 display the direct, mediating, and moderating results. Table 4 (Model 1) displays that CP_pdt is statistically significant with product innovation performance (β=35.495); thus, H1a is supported. When involving customers in product development, the expected value of a firm's product innovation performance will add 35.495 percentage points. This increase implies a positive, statistically significant impact of CP_pdt on the firm's product innovation performance. Table 4 (Model 2) shows that SP_pdt has a significantly positive impact on product innovation performance (β=35.579); thus, H1c is supported.

The results of ordered logit models in Table 5 (Model 1) reveal that CP_pcs are statistically significant with process innovation performance at the 1% level (β=2.018); thus, H1b is supported. This suggests that firms engaging customers in process innovation are more likely to realize cost reduction, quality improvement, or both than those not involving CP_pcs. Specifically, a one-unit increase in CP_pcs—that is, moving from 0 (not involving CP_pcs) to 1 (involving CP_pcs)—results in an increase of 2.018 in the log odds of process innovation performance moving to a higher category. Similarly, Model 3 in Table 5 illustrates that SP_pcs has a direct impact on process innovation performance (β=1.886), supporting H1d.

The results of Model 2 and Model 3 in Table 6 indicate that both CP_pdt (β=1.089) and CP_pcs (β=1.341) are significantly related to absorptive capacity, demonstrating that H2a and H2b are supported. H2c and H2d are also supported, as shown by the results of Model 4 and Model 5 in Table 6, which indicate that SP_pdt and SP_pcs are both strongly associated with absorptive capacity. When customers or suppliers are involved in product or process development, the predicted value of a firm's absorptive capacity increases largely, which suggests that CP_pdt, CP_pcs, SP_pdt, and SP_pcs have a positive and statistically significant influence on the firm's absorptive capacity.

Model 5 in Table 4 (β=7.541) and Model 5 in Table 5 (β=0.508) present that absorptive capacity is significantly related to product innovation performance and process innovation performance in the presence of CP and SP, supporting H3a and H3b, respectively. This suggests that firms with higher absorptive capacity appear to translate more external knowledge into product and process innovation performance in the market.

The impacts of CP and SP on both types of innovation performance are hypothesized to be mediated by absorptive capacity. As previously mentioned, both CP_pdt and CP_pcs show a positive relationship with absorptive capacity, which in turn greatly improves product and process innovation performance. Furthermore, the direct effects of CP_pdt on product innovation performance (Model 3, Table 4) and CP_pcs on process innovation performance (Model 2, Table 5) decrease with the introduction of the mediator variable absorptive capacity, though they remain significant. These findings demonstrate that the link between CP_pdt, CP_pcs, and an SEM's innovation performance is partially mediated by absorptive capacity (Hayes, 2017). Specifically, the significant indirect effects of CP_pdt (coefficient = 1.135×7.435=8.439) and CP_pcs (coefficient = 1.468×7.435=10.91) highlight the critical role of absorptive capacity in enhancing the impact of CP in product and process innovation, which implies that firms with higher absorptive capacity are better positioned to utilized customer input effectively, leading to superior innovation performance.

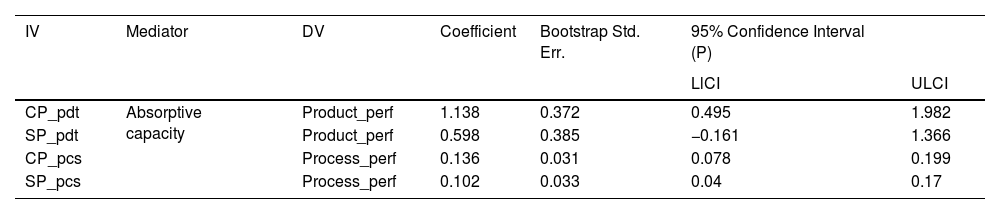

Additionally, both SP_pdt and SP_pcs are positively associated with absorptive capacity, which then significantly enhances the performance of product and process innovation. The addition of the mediator variable absorptive capacity reduces but does not eliminate the direct impacts of SP_pdt on product innovation performance (Model 4, Table 4) and SP_pcs on process innovation performance (Model 4, Table 5). These results show that absorptive capacity acts as a partial mediating factor in the relationship between SP_pdt, SP_pcs, and innovation performance (Hayes, 2017). The significant indirect effect of SP_pcs (coefficient = 1.099×7.435=8.17) emphasizes the essential role of absorptive capacity in transforming the impact of SP in process innovation. However, the indirect effect of SP_pdt (coefficient = 0.511×7.435=3.799) is not statistically significant, as displayed in Table 7, indicating that the impact of SP_pdt through absorptive capacity may be more variable in this context.

Mediating effect examination.

| IV | Mediator | DV | Coefficient | Bootstrap Std. Err. | 95% Confidence Interval (P) | |

|---|---|---|---|---|---|---|

| LlCI | ULCI | |||||

| CP_pdt | Absorptive capacity | Product_perf | 1.138 | 0.372 | 0.495 | 1.982 |

| SP_pdt | Product_perf | 0.598 | 0.385 | −0.161 | 1.366 | |

| CP_pcs | Process_perf | 0.136 | 0.031 | 0.078 | 0.199 | |

| SP_pcs | Process_perf | 0.102 | 0.033 | 0.04 | 0.17 |

Note: IV: Independent variable; DV: Dependent variable; P: percentile confidence interval; Bootstrap resample = 1000; LLCI = Lower limit confidence interval; ULCI = Upper limit confidence interval.

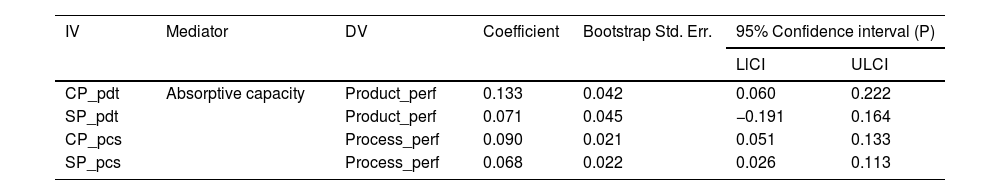

The bootstrapping method is also used in this study to investigate the mediating effects of absorptive capacity. Table 7 exhibits that the mediating influence of CP_pdt on product innovation performance via absorptive capacity is significant, as the confidence interval does not contain 0. A similar situation is observed for CP_pcs and SP_pcs on process innovation performance. However, the mediating effect of absorptive capacity between SP_pdt and product innovation performance is not significant, as the confidence interval includes 0.

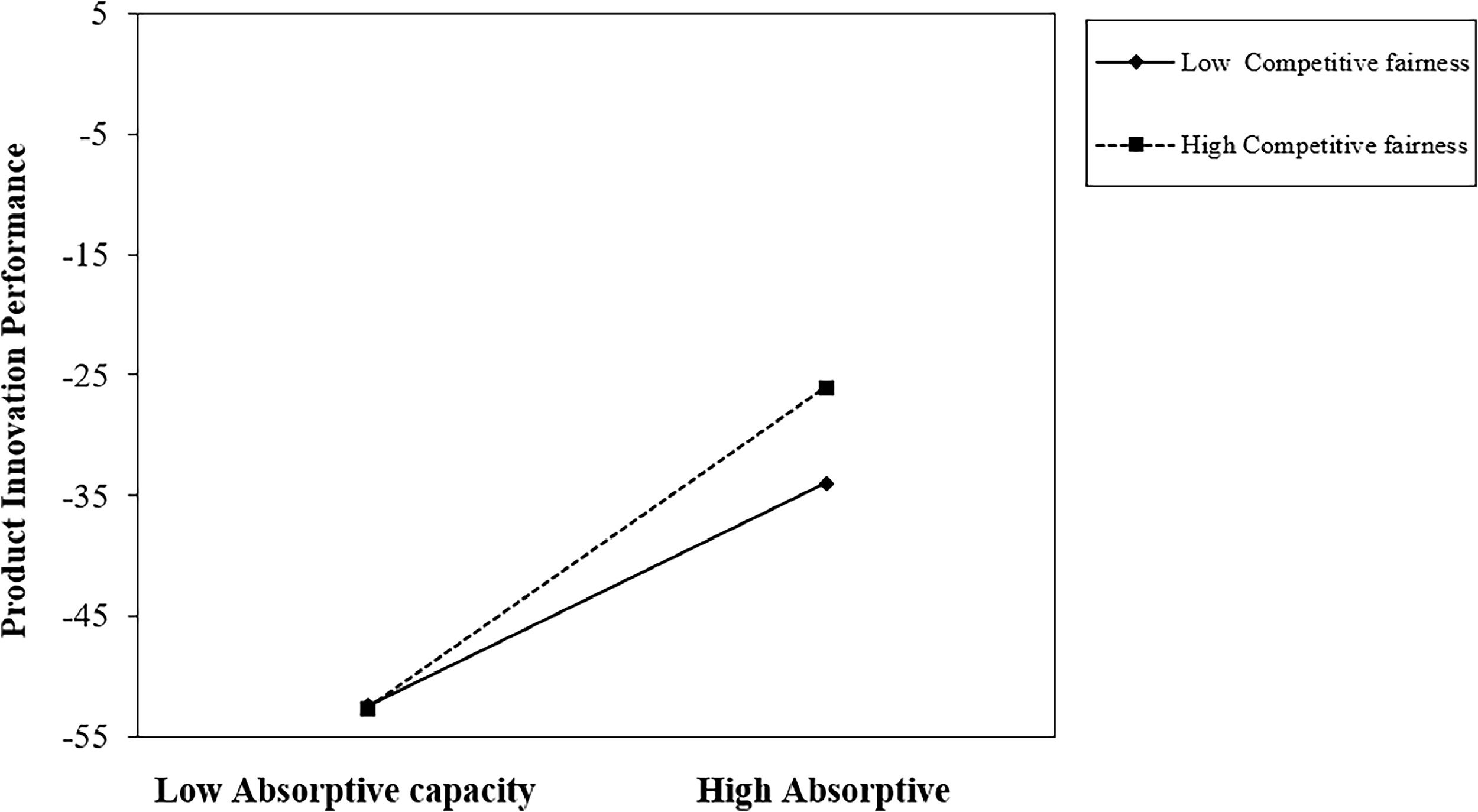

The moderating effect of competitive fairness is displayed in Model 6 in Table 4 and Model 6 in Table 5. Before the interaction, the relevant variables were mean-centered to reduce the likelihood of multicollinearity. The results show that competitive fairness positively moderates the impact of absorptive capacity on product innovation performance (β=0.071). Thus, H4a is supported. This finding indicates that firms operating in a healthier business environment better translate their absorptive capacity into successful product innovations. As to process innovation performance, the result is not statistically significant. Thus, H4b is not supported. Fig. 2 displays the relationship effect to help discover the moderating effect of competitive fairness, in which high competitive fairness enables a higher positive relationship between absorptive capacity and product innovation performance.

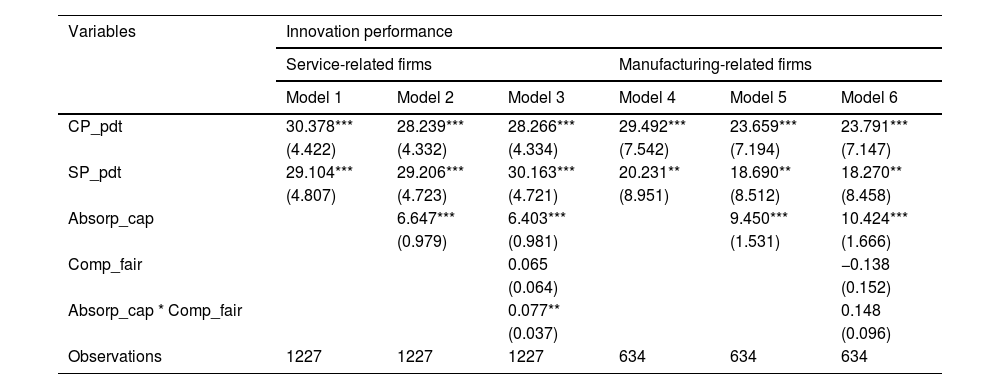

Additional analysisGiven that manufacturing firms usually have a greater need for R&D, which leads to high absorptive capacity, we conducted a subsample investigation to examine the variations in the effects of CP/SP between manufacturing- and service-related firms. As Table 8 shows, our analysis indicates that while the direct effects of CP and SP on product innovation performance are significant for both industries, the coefficients are higher for service-related industries. However, the direct influence of absorptive capacity is greater for manufacturing-related firms. This disparity may be explained by the fact that manufacturing firms have a higher demand for external knowledge that they can absorb and incorporate into their development process, thus enhancing their product innovation performance (Lyu et al., 2023). Additionally, the moderating effect of competitive fairness is significant only in service-related industries, suggesting that these industries are more sensitive to the business environment.

Grouping regression results according to industry.

| Variables | Innovation performance | |||||

|---|---|---|---|---|---|---|

| Service-related firms | Manufacturing-related firms | |||||

| Model 1 | Model 2 | Model 3 | Model 4 | Model 5 | Model 6 | |

| CP_pdt | 30.378*** | 28.239*** | 28.266*** | 29.492*** | 23.659*** | 23.791*** |

| (4.422) | (4.332) | (4.334) | (7.542) | (7.194) | (7.147) | |

| SP_pdt | 29.104*** | 29.206*** | 30.163*** | 20.231** | 18.690** | 18.270** |

| (4.807) | (4.723) | (4.721) | (8.951) | (8.512) | (8.458) | |

| Absorp_cap | 6.647*** | 6.403*** | 9.450*** | 10.424*** | ||

| (0.979) | (0.981) | (1.531) | (1.666) | |||

| Comp_fair | 0.065 | −0.138 | ||||

| (0.064) | (0.152) | |||||

| Absorp_cap * Comp_fair | 0.077** | 0.148 | ||||

| (0.037) | (0.096) | |||||

| Observations | 1227 | 1227 | 1227 | 634 | 634 | 634 |

Note: The control variables contain all the control variables described above. They are absent from the list to save space.

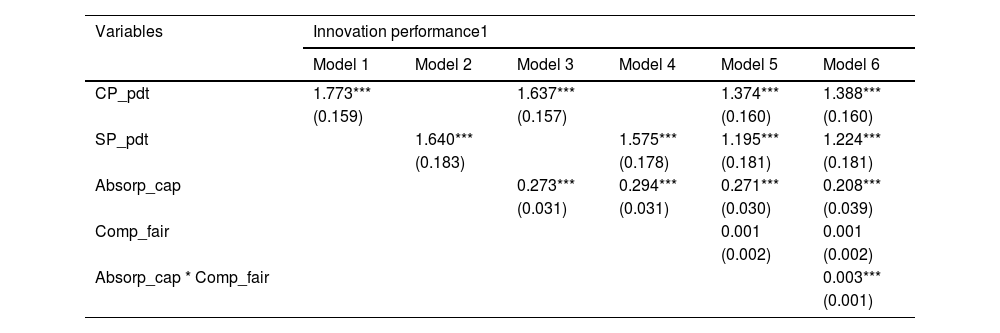

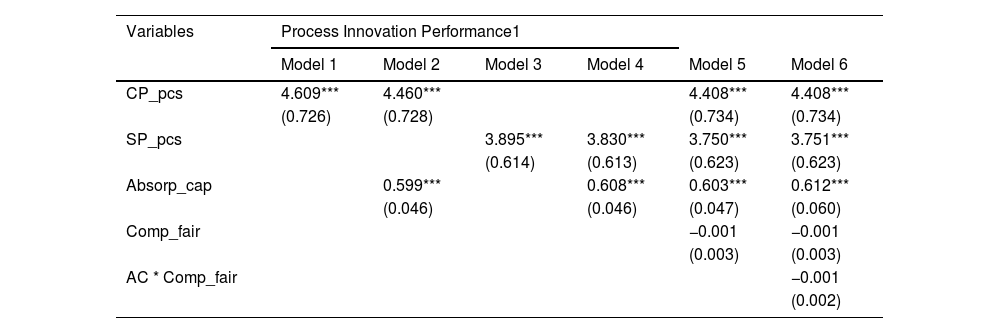

Robustness checks using alternative measurements of innovation performance, including product and process innovation, confirmed the stability of the results. Tables 9 and 10 present the findings using alternative measurements. They demonstrate that absorptive capacity remains strongly related to innovation performance in the presence of CP and SP. Table 11 shows the mediating effects of absorptive capacity. These findings reaffirm that the relationship between CP/SP and two types of innovation performance is partially mediated by absorptive capacity, except for the effect of SP_pdt on product innovation performance, which is consistent with the baseline regression results.

Results of direct effect, mediating effect, and moderating effect with alternative measurement of product innovation performance.

| Variables | Innovation performance1 | |||||

|---|---|---|---|---|---|---|

| Model 1 | Model 2 | Model 3 | Model 4 | Model 5 | Model 6 | |

| CP_pdt | 1.773*** | 1.637*** | 1.374*** | 1.388*** | ||

| (0.159) | (0.157) | (0.160) | (0.160) | |||

| SP_pdt | 1.640*** | 1.575*** | 1.195*** | 1.224*** | ||

| (0.183) | (0.178) | (0.181) | (0.181) | |||

| Absorp_cap | 0.273*** | 0.294*** | 0.271*** | 0.208*** | ||

| (0.031) | (0.031) | (0.030) | (0.039) | |||

| Comp_fair | 0.001 | 0.001 | ||||

| (0.002) | (0.002) | |||||

| Absorp_cap * Comp_fair | 0.003*** | |||||

| (0.001) | ||||||

Note: The control variables contain all the control variables described above. They are absent from the list to save space.

Results of direct effect, mediating effect, and moderating effect with alternative measurement of process innovation performance.

| Variables | Process Innovation Performance1 | |||||

|---|---|---|---|---|---|---|

| Model 1 | Model 2 | Model 3 | Model 4 | Model 5 | Model 6 | |

| CP_pcs | 4.609*** | 4.460*** | 4.408*** | 4.408*** | ||

| (0.726) | (0.728) | (0.734) | (0.734) | |||

| SP_pcs | 3.895*** | 3.830*** | 3.750*** | 3.751*** | ||

| (0.614) | (0.613) | (0.623) | (0.623) | |||

| Absorp_cap | 0.599*** | 0.608*** | 0.603*** | 0.612*** | ||

| (0.046) | (0.046) | (0.047) | (0.060) | |||

| Comp_fair | −0.001 | −0.001 | ||||

| (0.003) | (0.003) | |||||

| AC * Comp_fair | −0.001 | |||||

| (0.002) | ||||||

Note: The control variables contain all the control variables described above. They are absent from the list to save space.

Mediating effects of alternative measurement of product and process innovation performance.

| IV | Mediator | DV | Coefficient | Bootstrap Std. Err. | 95% Confidence interval (P) | |

|---|---|---|---|---|---|---|

| LlCI | ULCI | |||||

| CP_pdt | Absorptive capacity | Product_perf | 0.133 | 0.042 | 0.060 | 0.222 |

| SP_pdt | Product_perf | 0.071 | 0.045 | −0.191 | 0.164 | |

| CP_pcs | Process_perf | 0.090 | 0.021 | 0.051 | 0.133 | |

| SP_pcs | Process_perf | 0.068 | 0.022 | 0.026 | 0.113 | |

Note: LICI: lower limit confidence interval; ULCI: upper limit confidence interval.

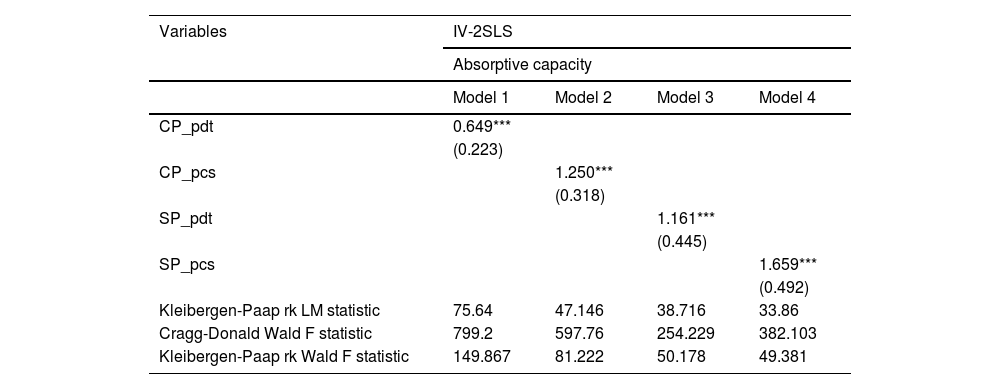

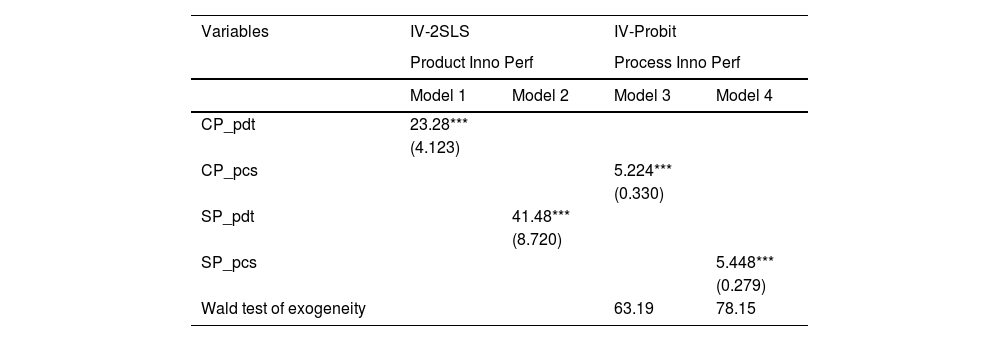

Based on the outcomes of the basic regression, the analysis initially considered customer/supplier participation as exogenous. However, customer/supplier participation is likely the result of a strategic decision. To mitigate potential endogeneity issues in the baseline regression model, such as the bidirectional influence between customer/supplier participation in product or process innovation and absorptive capacity of SMEs, which could undermine the empirical findings’ validity, this study implemented the instrumental variable (IV) approach to address these issues (Germann et al., 2015). The results confirm that the observed relationships are robust to potential endogeneity concerns.

Drawing inspiration from Jean et al. (2014), this research utilized a variable measured by if the cooperative firm involved in customer/supplier participation in product innovation is local for CP_pdt and SP_pdt, and applied the same for process innovation with CP_pcs and SP_pcs. The rationale is that local cooperation influences collaboration propensity, satisfying the relevance condition, while not directly affecting absorptive capacity or innovation performance, thus meeting the exogeneity condition. The endogeneity test results, reported in Tables 12 and 13, show that the core explanatory variables CP_pdt, SP_pdt, CP_pcs, and SP_pcs remained significantly positive after addressing endogeneity, reaffirming the reliability and robustness of the baseline regression results.

Endogeneity test-1.

| Variables | IV-2SLS | |||

|---|---|---|---|---|

| Absorptive capacity | ||||

| Model 1 | Model 2 | Model 3 | Model 4 | |

| CP_pdt | 0.649*** | |||

| (0.223) | ||||

| CP_pcs | 1.250*** | |||

| (0.318) | ||||

| SP_pdt | 1.161*** | |||

| (0.445) | ||||

| SP_pcs | 1.659*** | |||

| (0.492) | ||||

| Kleibergen-Paap rk LM statistic | 75.64 | 47.146 | 38.716 | 33.86 |

| Cragg-Donald Wald F statistic | 799.2 | 597.76 | 254.229 | 382.103 |

| Kleibergen-Paap rk Wald F statistic | 149.867 | 81.222 | 50.178 | 49.381 |

Note: Robust standard errors in parentheses for IV-2SLS. *** p < 0.01, ** p < 0.05, * p < 0.1.

Endogeneity test-2.

| Variables | IV-2SLS | IV-Probit | ||

|---|---|---|---|---|

| Product Inno Perf | Process Inno Perf | |||

| Model 1 | Model 2 | Model 3 | Model 4 | |

| CP_pdt | 23.28*** | |||

| (4.123) | ||||

| CP_pcs | 5.224*** | |||

| (0.330) | ||||

| SP_pdt | 41.48*** | |||

| (8.720) | ||||

| SP_pcs | 5.448*** | |||

| (0.279) | ||||

| Wald test of exogeneity | 63.19 | 78.15 | ||

Note: Robust standard errors in parentheses for IV-2SLS (Model 1 and Model 2), Standard errors in parentheses for IV-Probit (Model 3 and Model 4). The controls stated above are all included. Both industry dummy variables and regions dummy variables are included. *** p < 0.01, ** p < 0.05, * p < 0.1.

The empirical insights from this study shed light on the contextual and inherent mechanisms that underpin the relationship between CP/SP and product and process innovation performance. The findings reveal that SMEs can improve both types of innovation performance by involving customers or suppliers in the development of their products and processes. Additionally, CP and SP have a significant direct effect on absorptive capacity, which in turn influences innovation performance. This indicates that the benefits of CP and SP are channeled by absorptive capacity. Furthermore, the business environment has a major impact on how much one SME's product innovation performance improves as absorptive capacity increases. Overall, this research provides a deeper understanding of how the interaction between internal resources and external cooperation can promote the effectiveness of CP and SP strategies in driving product and process innovation performance. The specific discussion is as follows:

On the one hand, the relationship between CP/SP and innovation performance has a direct positive effect on both product and process innovation. Specifically, CP in product innovation enhances the development of novel product features, aligning them with market needs, which is consistent with the findings of Obal et al. (2024). Similarly, customer insights into process innovation help firms adjust their processes to improve product quality and efficiency. The positive effect of CP_pcs corresponds with the findings of Terjesen and Patel (2017), who emphasize the positive strategic value of CP in process innovation, and the study of Tsinopoulos et al. (2018), who suggest that customer-driven innovation strategies increase product quality by matching manufacturing processes with actual user requirements. Similarly, SP contributes to both product and process innovation performance. SP allows firms to leverage suppliers’ specialized knowledge and technological advancements to obtain not only innovative products but also enhanced product quality and more efficient production processes, which ultimately contribute to both types of innovation performance.

On the other hand, the hypothesis that CP indirectly promotes innovation performance through absorptive capacity is supported. Absorptive capacity enables the effective integration and application of customer insights into both product and process innovation. Similarly, SP contributes to innovation by providing specialized knowledge and resources (Wagner, 2012). Absorptive capacity acts as a mediator by allowing firms to effectively assimilate supplier knowledge, thereby improving innovation performance (Najafi-Tavani et al., 2016). It is worth mentioning that, the mediating effect between SP_pdt and product innovation performance is not statistically significant. This may be because supplier knowledge is often highly tacit and specialized (Sikombe & Phiri, 2019), and suppliers typically act as innovators, directly participating in product innovation rather than sharing tacit knowledge for firms to integrate.

In addition, the hypothesis that the business environment positively moderates the relationship between absorptive capacity and product innovation performance is supported, while the same effect for process innovation is not supported. High competitive fairness encourages firms to engage in open innovation, leveraging absorptive capacity to transform external knowledge into product innovation, which ensures that efforts to acquire new knowledge will not be undermined by unfair practices, thus promoting innovation (Qiu et al., 2009; Tsai & Yang, 2013). For process innovation, the required knowledge may not be as specialized, so the demand for fair competition is relatively lower. As a result, the moderating effects of the business environment may not be significant.

Theoretical implicationsThis study builds on the notion that customers and suppliers act as external resources, with CP and SP converting customers and suppliers knowledge into capabilities to enhance firms’ innovation performance (Cui & Wu, 2018; Najafi-Tavani et al., 2013). In doing so, this study contributes to theoretical reflections on several aspects.

First, this research addresses the need for a more intricate comprehension of how CP and SP influence product and process innovation performance in SMEs (Hoyer et al., 2010). The results reveal that CP and SP significantly enhance absorptive capacity, which is consistent with the notion that diverse knowledge during product development fosters the generation of new insights (Flor et al., 2018). Extensive CP or SP exposes SMEs to creative settings and heterogeneous knowledge, which are required to integrate customer and supplier knowledge into product and process development frameworks (Mazzola et al., 2015). However, few empirical studies have examined this relationship. This advances open innovation discussions by emphasizing the role of external players, such as customers and suppliers, in innovation strategies. It also extends the dynamic capabilities framework by demonstrating how CP and SP improve a firm's ability to integrate, build, and reconfigure internal and external competencies (Sáenz et al., 2014).

Second, this study shows a direct relationship between absorptive capacity and product and process innovation performance in SMEs, aligning with prior research (Audretsch et al., 2023; Tsai, 2001). A firm's internal learning capacity shapes its ability to absorb new information from external partners (Cohen & Levinthal, 1990). Investment in absorptive ability enables SMEs to effectively assimilate and transform knowledge from these partners. The findings indicate that greater absorptive capacity enhances the likelihood of successfully utilizing new information for both breakthrough innovation and process improvement, leading to improved innovation outcomes in both product and process innovation. This supports the current understanding of innovation strategy, emphasizing the importance of open innovation strategy, particularly in SMEs (Santoro et al., 2018).

Third, this study finds that the business environment positively moderates the link between absorptive capacity and product innovation performance. This highlights the importance of creating a healthy business environment and facing challenges actively, which supports the effective utilization of absorptive capacity for innovation. The findings improve our understanding of the nuanced interplay between business environment factors, absorptive capacity, and product innovation outcomes in SMEs, identifying the boundary conditions under which absorptive capacity most effectively contributes to innovation performance. This provides a new perspective on the strategic management of knowledge and innovation in competitive and technologically evolving markets.

Managerial implicationsFirst, the outcomes show that involving customers or suppliers plays a critical role in enhancing innovation performance. CP is crucial for SMEs to identify market opportunities, access diverse customer needs, and ensure product and process offerings meet market demands. CP can help firms absorb customer knowledge, understand their requirements, resolve product issues, and adjust to market shifts. On the other hand, the implementation of SP enables firms to optimize resource utilization and grants access to professional knowledge, thereby expanding their pool of experience for the development of innovative products and efficient operations.

Second, SMEs should improve their absorptive capacity to assimilate and transform information from customers and suppliers. This improvement fosters collective experience in both product and process innovation, as well as reciprocal advantages through knowledge-sharing and problem-solving collaboration with various partners. Additionally, it is imperative for SME managers to distinguish between the roles of customers and suppliers in the innovation process—suppliers contribute technical know-how, while customers provide market insights.

Third, governments should foster an atmosphere with highly competitive fairness, where firms could optimize their innovation potential through high absorptive capacity. SMEs should also promote competitive fairness within their industries. In such a business environment, SMEs can compete more effectively, attract valuable collaborations, and leverage their absorptive capacity in the innovation process, thereby encouraging innovation performance. By strategically focusing on absorptive capacity, firms can better assimilate and utilize external knowledge, thereby compensating for the difficulties encountered in the competitive market.

Limitations and future researchThis study has several limitations. First, our examination focuses on CP and SP. Future research could investigate collaboration with other partners, such as research institutions and the government. It would be valuable to compare the effects of the various partners in future studies. Second, further investigation is required to explore the different forms of relationships that customers and suppliers can have, such as familial or friend linkages, which encourage communication and knowledge exchange to some extent. Finally, this study is limited to SMEs in China, which may affect the generalizability of the findings. Future studies should explore similar relationships in different cultural and economic contexts to validate and extend the findings.

CRediT authorship contribution statementBin Sang: Writing – review & editing, Writing – original draft, Validation, Methodology, Formal analysis, Data curation, Conceptualization, Software. Rafidah Md Noor: Writing – review & editing, Supervision, Project administration, Conceptualization, Validation. Ezlika Mohd Ghazali: Visualization, Supervision, Formal analysis, Conceptualization. Nasrin Aghamohammadi: Validation, Supervision, Conceptualization, Investigation.

This work was supported by the Fundamental Research Funds for the Provincial Universities of Zhejiang [grant number 2024ZD25].