Nickel-Titanium (NiTi) archwires have been widely used for initial alignment in order to produce light continuous forces and help reduce the risk of damage to the periodontal ligament. The objective of this study was to obtain the number of cycles that NiTi archwires withstand in flexural fatigue. Sixty circular 0.016” archwires from ORMCO (20), GAC (20) and 3M (20) were tested at 37 °C. Roth brackets (0.022x0.025”) were bonded to acrylic teeth. A universal testing machine (Instron 5567) was used until fracture occurred. A report of cycles fatigue was made for each sample. The results were statistically tested using the one-way ANOVA Test and a Tukey Test (p < 0.001). The fractured surfaces were observed with a metallographic microscope (125X) to evaluate the fracture type. ORMCO archwires showed more elasticity than 3M and GAC archwires.

Los alambres de níquel-titanio han sido los arcos de elección para la nivelación dental provocando fuerzas ligeras para crear movimientos sin daño al periodonto. El objetivo de este estudio fue determinar el número de ciclos que soportó un alambre de níquel-titanio a la fatiga en un ensayo de flexión. Se probaron 60 arcos redondos de 0.016” de ORMCO (20), GAC (20) y 3M (20) a 37 °C. Se usaron brackets Roth (0.022x0.025”) adheridos a dientes de acrílico de un tipodonto para sujetar los arcos. Una máquina universal de pruebas mecánicas fue usada para hacer la prueba de fatiga hasta obtener la fractura del arco. Se reportan los ciclos que cada muestra soportó. Los resultados requirieron de un análisis de varianza (ANOVA) de una vía con prueba de Tukey (p < 0.001). Las superficies fracturadas fueron examinadas en un microscopio metalográfico a 125X para observar el patrón de fractura. Se encontró que los arcos ORMCO presentan mayor elasticidad que los arcos de 3M y GAC.

Within the main materials in orthodontics archwires have proved to be of great interest, since they cause the necessary biomechanical forces to create tooth movement when working with brackets. It is recommended to use lighter forces so as not to damage the periodontum.1 It has been suggested that the forces applied to teeth must be between 0.015 and 5 N.2 Therefore, the specialist who was interested in obtaining better results began using nickel-titanium wires which were introduced in the 70’s. NiTi archwires contributed significantly to the evolution of orthodontic treatment. One of their main properties is the super elasticity when they are bent and the minimal plastic deformation.3–8 They produce continuous and light forces for a period of weeks or months with memory capacity thus producing tooth movements, without causing damage to the periodontum.9–11 About that matter, Gurgel12 et al recommended to select the ideal archwire depending on the degree of crowding that the patient presents to avoid any injury, both to the soft and hard tissues.

NiTi archwires are subjected to loads and deflections during chewing with the risk of a fracture or a plastic deformation, that is why Farnaz1 et al., Eggeler13 et al. and Tabanli14 et al recommend not to force the archwires in areas where crowding is severe, since the over-deflecting the wire beyond their elastic limit will cause fracture.

That is why when using these arches it is recommended that the wire is high quality with a good limit deflection and that does not deform under chewing loads. When an archwire begins deteriorating, this buildup causes fatigue and is generally associated with a cracked surface and subsequent growth of the crack. If there is a good wire finishing surface, the wires expected duration increases.13-17

It is important to consider what Torstein15 mentions about the metallurgical substrate for super elasticity and about NiTi arcwhwire memory that has the ability to easily switch from martensite to austenite phase. This transformation may occur by means of a force or by temperature changes. Torstein stated that in the martensite phase, the archwire tends to be more flexible; however, with a rise in temperature, it will begin to recover its original shape.16 Due to these properties, Tabanli14 et al., considered that these phases alter the wire’s life when subjected to cyclical forces (fatigue). When subjected to a certain force, archwires begin to show changes (martensite to austenite) that deteriorate NiTi archwires.

When analyzing the contributions of the authors mentioned above, a curiosity to find out more about the behavior of the NiTi arches, to observe the behavior of the fatigue and to establish the number of cycles required to produce a fracture emerges. When the archwires are inserted in the bracket’s slot, a clinical system that suffers fatigue fractures is represented. This is a phenomenon caused by cyclical forces that occur during mastication and that limit the wire’s lifespan.18

Masticatory force is approximately 756 N (170 lb); this range varies between individuals and the area of the oral cavity. In the molar area, masticatory forces are between 400 and 890 N (90 to 200 lb), in the incisor area between 89 and 111 N (20-55 lb) and in the premolar region between 133 and 334 N (30-75 lb)10,11 therefore when food is chewed and such forces are produced, with time, imperfections occur causing archwire fracture. This may be a risk since the wire might be swallowed by the patient and it also alters treatment phases thus delaying its finishing. Due to these circumstances, the aim of our study was to determine the number of cycles that a group of nickel- titanium wires endured in a three-point flexural test.

The hypothesis poses that there are statistically significant differences in the number of cycles for fracture in a flexural fatigue test between Ormco, 3M and GAC archwires.

MethodsSixty NiTi superelastic, round, 0.016” caliber archwires were selected, twenty per brand (3M: batch P5556, ORMCO: batch 06H280H and GAC: batch 06122101). For all the archwires, the side where the load was applied simulated dental movements at a 7 mm interbracket distance between the upper right second premolar and the first molar. This interbracket distance derived from the typical dimensions of permanent dentition maxillary teeth.

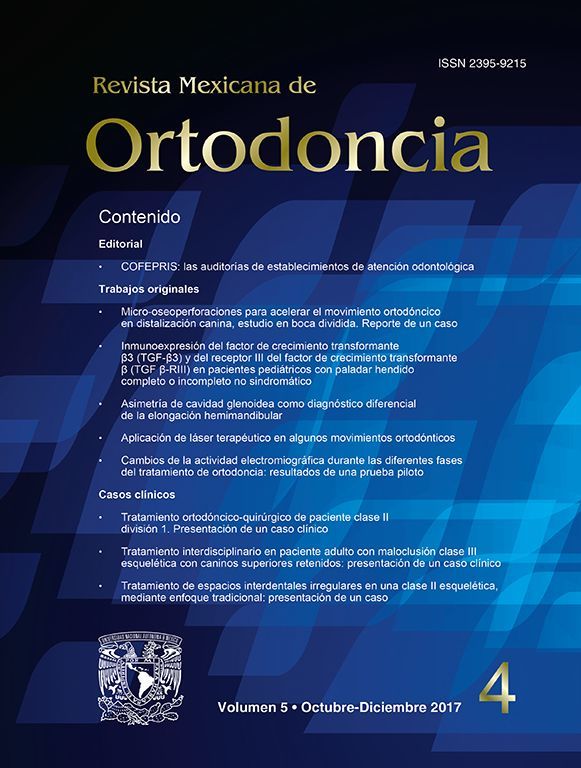

The samples were placed in a typodont with acrylic teeth in which Roth system (0.022 x 0.025”) brackets were bonded with methyl cyanoacrylate. Brackets were placed on the axial axis of the typodont teeth and the archwires were held within the bracket’s slot with ligature wire (0.010”, GAC). The flexural fatigue test was performed in a universal testing machine (Instron model 5567, Canton, Mass) with a speed of 80 mm/ minutes to produce a 1 mm deflection (Figure 1).

This speed simulated an adult patient’s 36±2 bites per minute. The test was carried out in a temperature- controlled chamber with an infrared light lamp (Heat ray Philips 250 W. Infrared, made in the U.S.A.) at 37°±2 °C, to simulate the conditions of the oral cavity. The archwire was flexed 1 mm, which by spring action of the same returned to its original position. This cyclical movement was repeated until fracture occurred.

The fracture pattern was observed under a metallographic microscope (Leitz Wetzlar) at 125X. The cycles that each sample endured were recorded.

A one-way ANOVA and a Tukey test were used to determine the statistical differences between archwires.

ResultsThe table I shows the average values and the standard deviation of the cycles that each sample endured. ORMCO archwires showed statistically significant differences with regard to GAC and 3M (p < 0.001);whilebetween GAC and 3M thebehavior was similar. ORMCO archwires endured more cycles than GAC (42%) and the 3M (54%). GAC supports more cycles than 3M (21%) when flexed cyclically 1mm at a 37 °C±2 °C temperature.

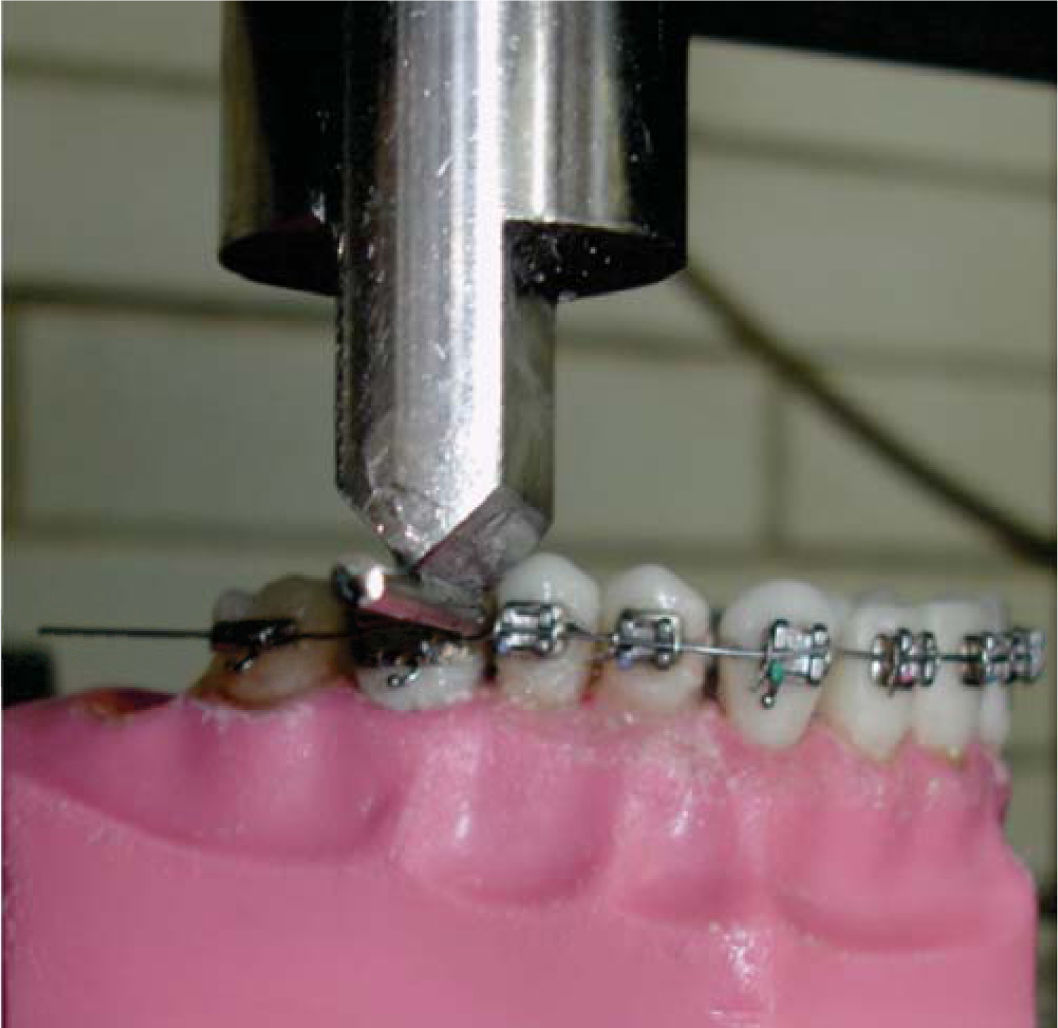

When observed under the metallographic microscope at 125X, it was found that the surface of the fractured archwires exhibited dented edges, roughness and color changes. The fractures features are shown in Figures 2 to 4.

DiscussionIt was found that NiTi archwires when flexed with constant forces fractured by the wear that the wire suffered. The deterioration due to friction wear in stainless steel wires has been investigated by Zhang et al.,19 Zhou20,21 and Neyman22 et al. who determined that the useful life of stainless steel wire subjected to fatigue is inversely proportional to the damage that they suffer from being worn by friction. Therefore, the more the steel wire wears, the more likely it will be that it suffers premature fracture.

It is important to mention that steel wires have a greater fatigue resistance than NiTi archwires.23

The temperature used in this study was the same as the one in the oral cavity (37 °C±2 °C), which was also applied by Wilkinson et al.24 They refer that in many studies conducted by leading researchers such as Nakano et al.,7 Mullins et al.25and Filleul et al.26 the temperature used was 37 °C, since it is the temperature of the oral cavity. Moore et al.27 preferred a temperature of 35.5 °C since he considered it more appropriate for in vitro wire testing in orthodontics.

The behavior presented in this study by 0.016” caliber NiTi round archwires was that they possessed super elasticity property as referred by several authors.3,9,15

Upon observation under metallographic microscope, the nickel-titanium archwires, showed serrated surfaces at the site where fracture occurred; Primack23 et al. mention that «fatigue accumulation» generally produces a crack originated in the surface that causes failure under a low number of cycles and then grows up to produce fracture. These events were identified by observing their samples under a microscope, which showed serrated surfaces with cracks and ridges that spread across the fracture site.

This finding is consistent with what we found in the 3M, GAC and ORMCO samples (Figures 2 to 4).

Conclusions- •

There are statistical significant differences between the three archwire commercial brands analyzed such as stated by our hypothesis.

- •

It was determined that Ormco archwires have more elasticity than the ones from GAC and 3M.