This paper addresses the design, simulation, commissioning and testing of an electrodynamometer (ED) to assess the dynamic performance of Electric Vehicles (EV). The EV-ED system is comprised of two electric machines coupled mechanically. The traction machine is a 7.75 kW Permanent Magnet Synchronous Motor which is controlled by means of a vector control and it is coupled mechanically to a similar machine which is used as a mechanical load. The load machine was fed by two DC/AC converters connected by the DC bus allowing bidirectional power flow. The electrodynamometer was controlled by means of a National Instruments electronic board and Labview software. Several load profiles and inertias were programmed to emulate an Electric Vehicle (EV). The traction machine drive was implemented with a PP75T120 Powerex Inverter. PWM generation and control strategy were implemented on a MC56F8357 Freescale Digital Signal Controller (DSC). The speed control of the traction machine was validated for different driving cycles. Matlab/Simulink simulations of the machine control and electrodynamometer along with experimental results illustrating the response of the machine control under the characteristic load profile of an EV are presented and analyzed. Traction and regenerative breaking stages are analyzed and discussed broadly.

Este artículo aborda el diseño, simulación, implementación y comprobación experimental de un electrodinamómetro (ED) con el objetivo fundamental de evaluar el desempeño dinámico de un vehículo eléctrico (EV). El sistema ED-EV está compuesto de dos máquinas eléctricas acopladas mecánicamente. La máquina de tracción es una máquina síncrona de imanes permanentes (PMSM) de 7.75 kW y su sistema de control es de tipo vectorial. La máquina esta acoplada mecánicamente con otra similar la cual es utilizada como máquina de carga. El electrodinamómetro fue implementado con dos convertidores CD/CA conectados entre sí por el bus de CD permitiendo un flujo de potencia bidireccional. El electrodinamómetro es controlado por medio de una tarjeta electrónica de National Instruments y Labview instalado en una computadora. Para emular el EV se programaron diferentes perfiles de carga e inercias. El accionamiento de la máquina de tracción fue implementado con un inversor Powerex del tipo PP75T120. La generación de las señales PWM y la estrategia de control fueron implementadas en un controlador digital de señales (DSC) de Freescale del tipo MC56F8357. El control de velocidad de la máquina de carga fue validado usando diferentes ciclos de manejo. Se presentan y analizan simulaciones en Matlab/Simulink del control de la máquina y del electrodinamómetro, así como resultados experimentales que ilustran la respuesta del control de la máquina de tracción con una carga que corresponde a un EV. Las etapas de tracción y frenado regenerativo son analizadas y discutidas ampliamente.

An electrodynamometer (ED) is aimed to emulate mechanical loads to test electrical machines. Most of the commercial EDs are comprised by a load machine which is operated by means of a torque control which is independent of the dynamics of the traction machine speed. This kind of ED is used to characterize motor drives working under steady state conditions. However, transport mechanical loads usually have a dynamic performance (regeneration, starting and stopping with high load torques) being the main cause of problems for the motor drives [1].

Dynamic loads present the inertia phenomena producing regeneration in the system, being impossible for an ED based on a passive load machine to emulate this kind of loads. To emulate dynamic loads a torque control dependent of the motor speed is needed [2] – [7].

There are some strategies reported in literature concerning ED control. In [8] a vector control is proposed and it is claimed an improvement of the dynamic response of the control. In [9] the torque control of the load machine is carried out using a Direct Torque Control strategy meanwhile in [10] the ED is controlled by means of genetic algorithms.

This paper addresses the design, simulation, commissioning and experimental validation of an ED which is able to emulate dynamic loads. The ED is comprised by a 7.75 kW Permanent Magnet Synchronous Machine (PMSM) which is used as a load machine and a similar PMSM used as a drive machine both machines are coupled mechanically and enable us to emulate the dynamics of an EV.

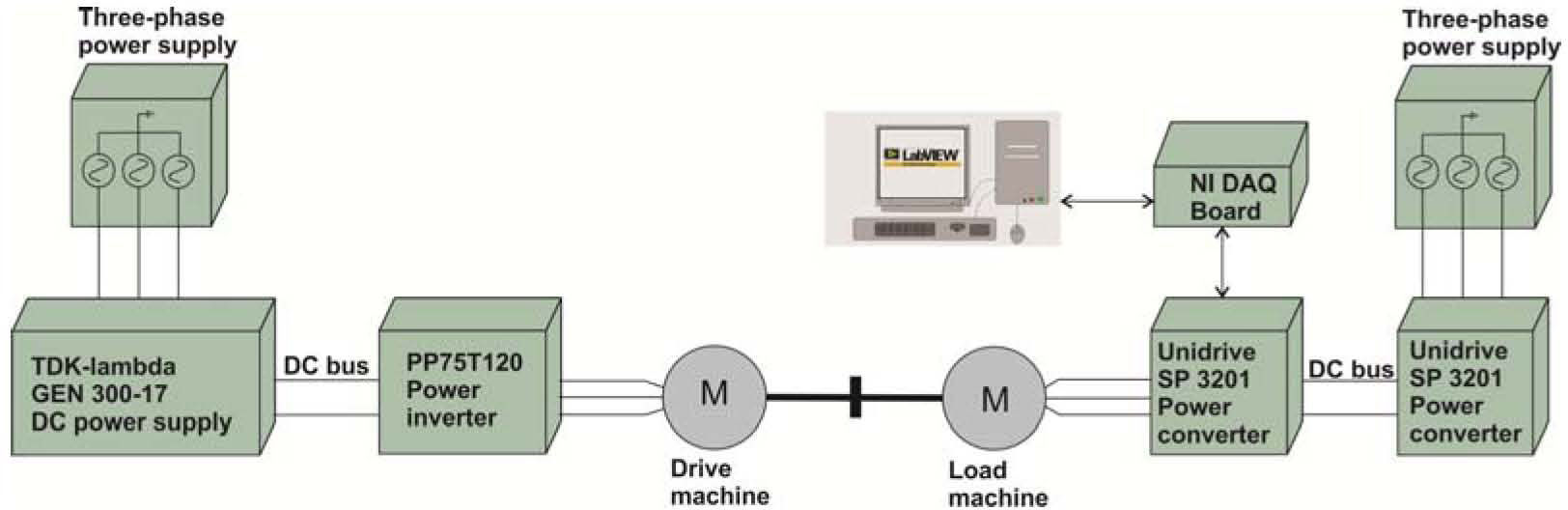

2Experimental setupFigure 1 illustrates a block diagram of the experimental setup. This is comprised by two power converters (Unidrive SP3201) connected by the DC bus, these converters are used to manage the power flow between the load machine and the grid.

The ED control was implemented on Labview, an NI USB6211 Data Acquisition Board was used as an interface between a PC and the Unidrive which drives the load machine. By means of an appropriate control of the ED different load profiles can be applied to the main machine (drive machine). When the load machine exerts an opposite mechanical torque to the drive machine emulating a dynamic load like that for an EV during its traction stage, the load machine works as a generator putting energy by means of the unidrives into the grid as illustrated in figure 1.

On the other hand if the load machine works as a motor then the load machine exerts a mechanical torque to the drive machine in the same direction at which it is spinning, emulating an EV during its regenerative braking stage putting energy into the DC bus by means of the PP75T120 Powerex converter.

The drive machine (traction machine if an EV is being emulated) was driven by a Powerex PP75T120 inverter which was fed by a TDK-Lambda GEN 300-17 power supply. The drive machine control and the PWM generation were implemented on a Freescale MC56F8357 Digital Signal Controller. Diodes connected in series with the power supply are used to block the energy regenerated by the traction machine and sent to the power supply.

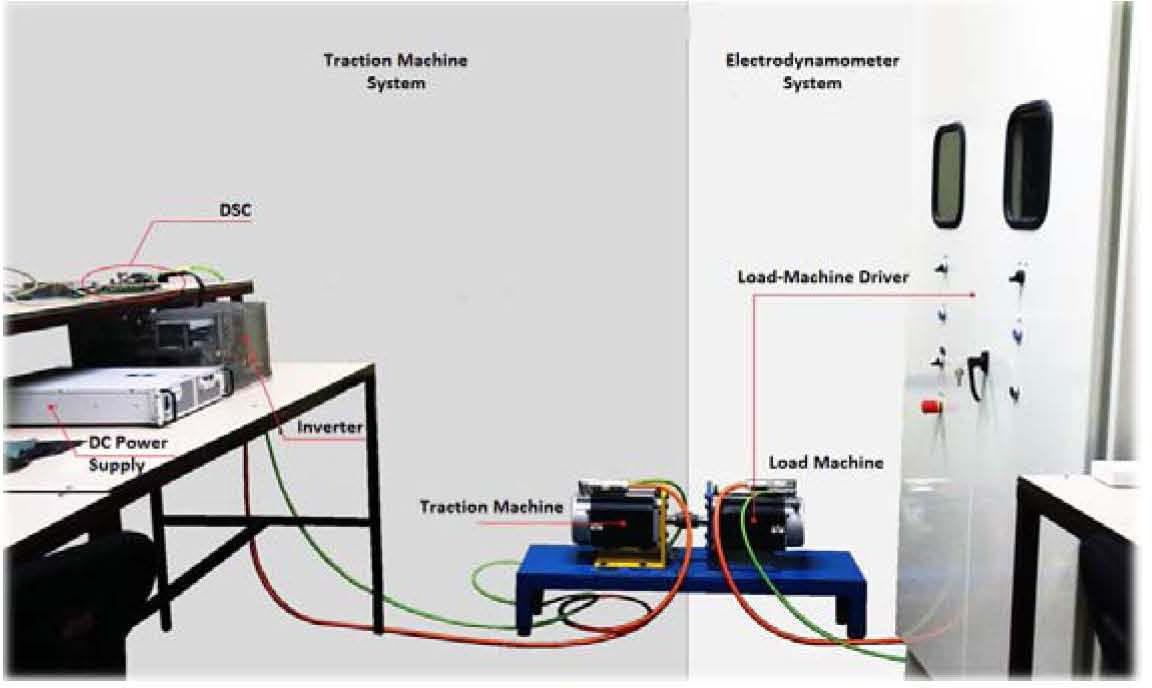

To emulate the regenerative braking stage of an EV braking resistors are needed to dissipate the regenerated energy. Data of the PMSMs are shown in appendix A. Figure 2 illustrates the experimental setup as it was implemented in the laboratory.

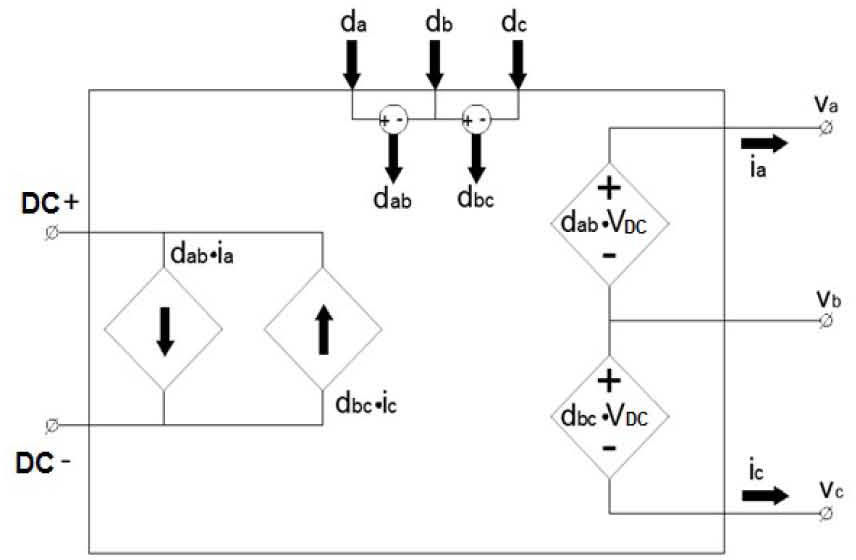

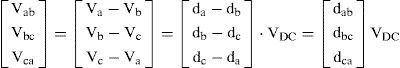

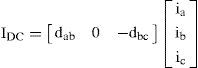

3Simulation of the traction motor -electrodynamometer systemIn order to speed up the simulations an average model of the inverter [11] was used as illustrated in figure 3. The average model is defined by the following set of equations

where da, db and dc are the PWM duty cycles corresponding to each phase.

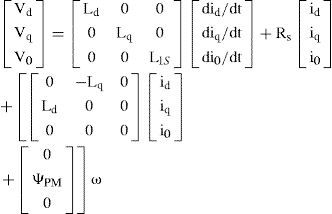

The dq PMSM model is given by [12]:

where, Te is the electromagnetic torque (N-m); vd, vq and v0 are the dq0 stator voltages (V), id, iq and i0 are the dq0 stator currents (A); ψpmis the permanent-magnet flux (Wb); Ld, Lq are the dq stator inductances (H); Lls is the leakage inductance (H); Rs is the stator resistance (Ω); p is the number of pole pairs and, ω is the electric speed of the rotor (rad/s).

As the machines used are PMSM with surface-mounted magnets then Ld=Lq and equation (4) becomes

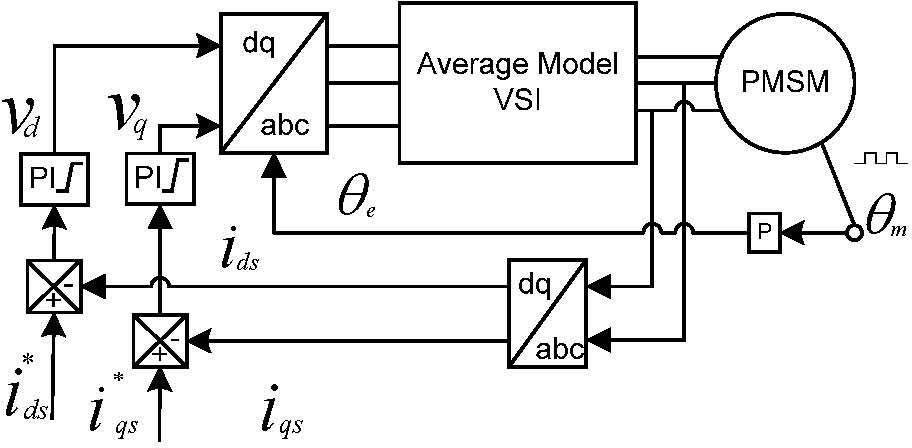

this equation reveals that the electromagnetic torque is proportional to the stator-current component q (iqs). The traction-machine control is based on a vector control strategy. Figure 4 illustrates this strategy which was simulated in Simulink. Simulations to assess the performance of the traction-machine vector-control and also to tune their control gains were carried out as illustrated in figure 4. Speed and current PI controllers were limited to avoid voltage and current overshoots that may damage the power electronic components. An anti-windup block was used to compensate the effect of the integral component of the controller for high values of the error signal [13].

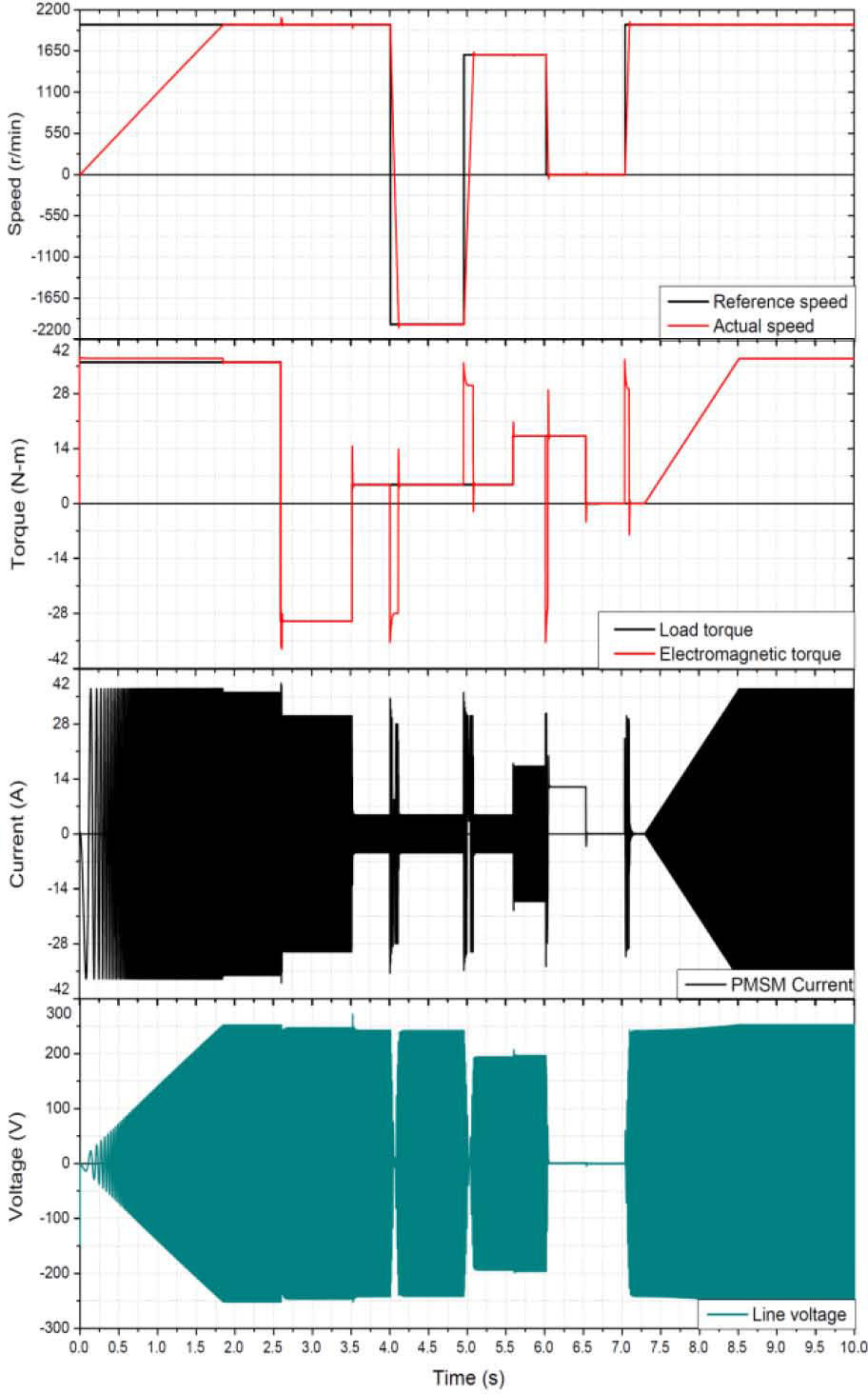

Figure 5 illustrates simulation results of the traction-machine vector-control. The reference-speed profile ωm* of the speed controller along with the actual speed of the traction machine are shown at the top plot of figure 5. The torque of the load machine and electromagnetic torque of the traction machine are illustrated just below the top plot. Different operation modes of the traction machine can be found in figure 5. From 0 to 1.7s the machine starts up and reaches its nominal speed which implies that the machine controller works satisfactorily even though the reference speed is a step waveform provoking a high initial error. The electromagnetic torque of the traction motor is constant resulting in a linear acceleration. The difference between the load torque and the electromagnetic torque is called the acceleration torque. At the end of the starting stage the acceleration torque becomes zero and the load and electromagnetic torques become the same.

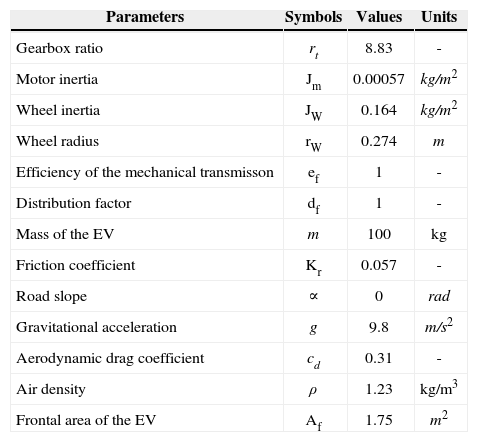

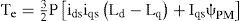

From 1.7 to 2.6s the traction machine is working as a motor. At 2.6s the load torque changes abruptly from positive to negative value and the traction machine works as a generator. At 3.5s the load torque changes from negative to positive value newly and the traction machine works as a motor again. For the remaining of the driving cycle the motor operation modes are changed carrying out starting up and braking stages. The current and voltage never overtake the motor nominal values which are listed in appendix A. The load-machine control is illustrated in figure 6. The speed control loop is not implemented as the ED speed is determined by the traction machine. As the machines are not operated at speeds higher than the base speed the weakening flux region operation is not needed and the reference value for the current component d is ids*=0 as illustrated in figures 4 and 6. According to eqn. 5 the reference value iqs* in figure 6 defines the value of torque produced by the load machine. Several load profiles can be emulated by modifying the reference values for the current component iqs*. The load applied to the traction machine by the dynamics of an EV can be easily emulated in the laboratory without needing to have an EV. This enable us to investigate on the performance of the traction machine in the same conditions as if it were fitted in the EV. For this work two 7.75 kW PMSMs were used which implies a small EV although the results can be extrapolated to a bigger vehicle. It is worth to point out that the EV load profile is not the only load that can be emulated but also any other load profile. The dynamic model of an EV [14] is described by equation (6):

where, Tm.- traction torque (N.m), rt- gearbox ratio, Jm.- motor inertia (Kg.m2), rw.- wheel radius (m), Jw.- wheel inertia (Kg.m2), ef.-efficiency of the mechanical transmission, df.-distribution factor, m.- mass of the vehicle (kg), V.- linear speed (m/s), Kr.- friction coefficient, á-road slope (rad), g.- gravitational acceleration (m/s2), Cd.- aerodynamic drag coefficient, p.- air density (kg/m3), Af.- frontal area of the vehicle (m2). By analyzing equation (6) it can be seen that the torque depends on the linear speed of the vehicle.

The relationship between the linear speed of the vehicle and the mechanical speed of the machine is given by:

In this way the linear speed of the vehicle is not needed. Once the traction torque has been calculated from (6), the current value iqs* for the load machine can be calculated by using eqn. (5), which is the reference current for the torque control loop in fig. 6. Simulation of the traction machine along with the ED was carried out in Simulink.

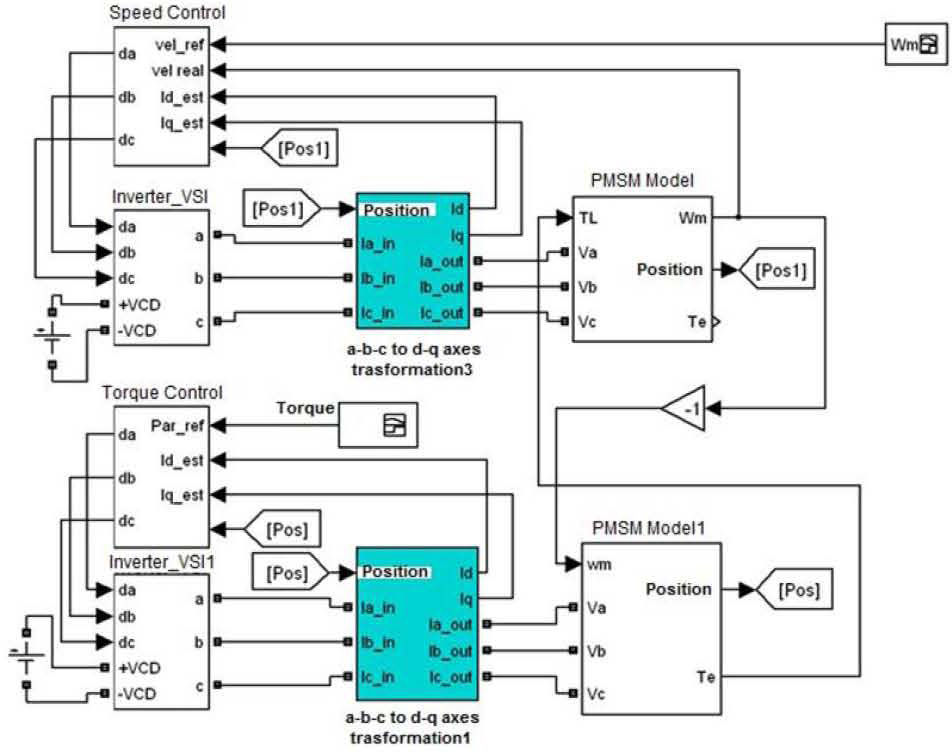

The general diagram of the simulated system is shown in figure 7.

The mechanical coupling between the machines is carried out as follows: the output electromagnetic torque of the load machine (PMSM Model 1) is connected to the input load torque of the traction machine (PMSM model) and the output speed of the drive machine is inverted and connected to the input speed of the load machine.

The reference speed is the only input to the traction-machine drive illustrated in fig. 4 meanwhile the load torque profile which is being emulated is the only input to the load machine (figure 6). If an EV is being emulated equation 6 is programmed in the block “torque” in figure 7.

Two tests were carried out to validate the ED. A fan load-profile (equation. 8) was emulated for the

where,

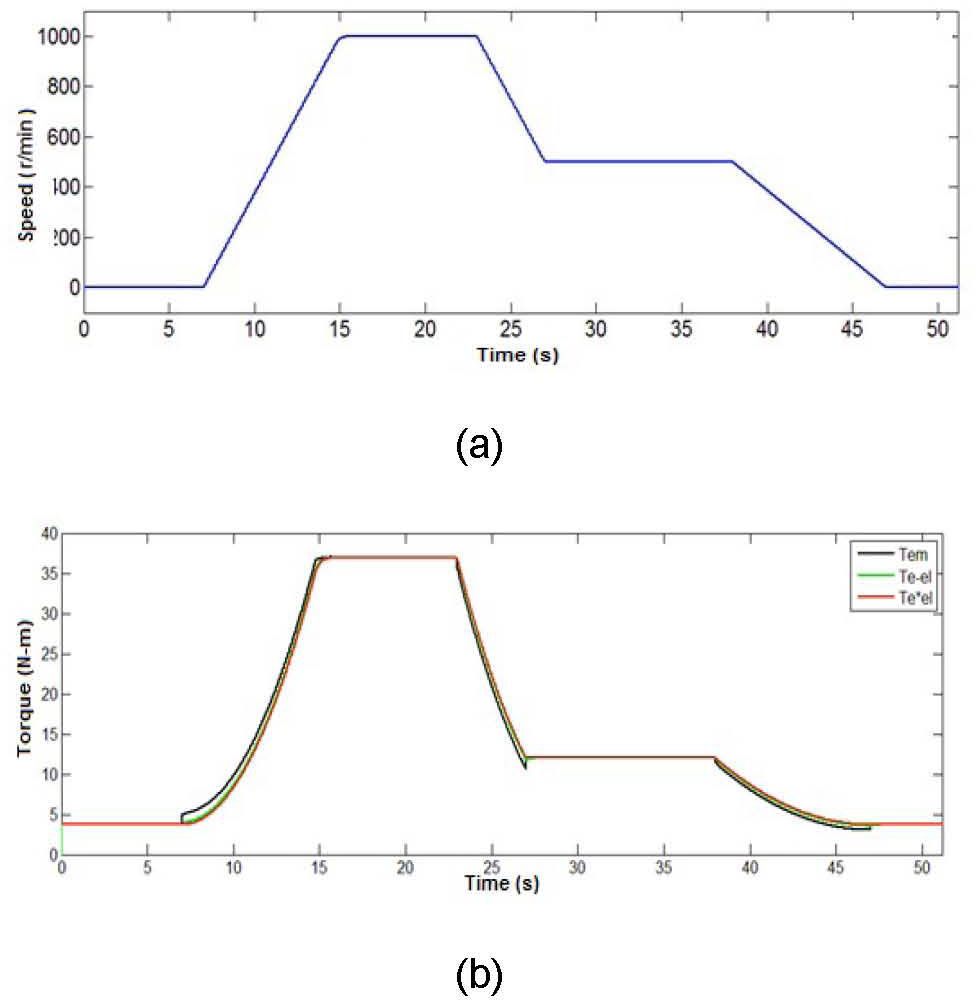

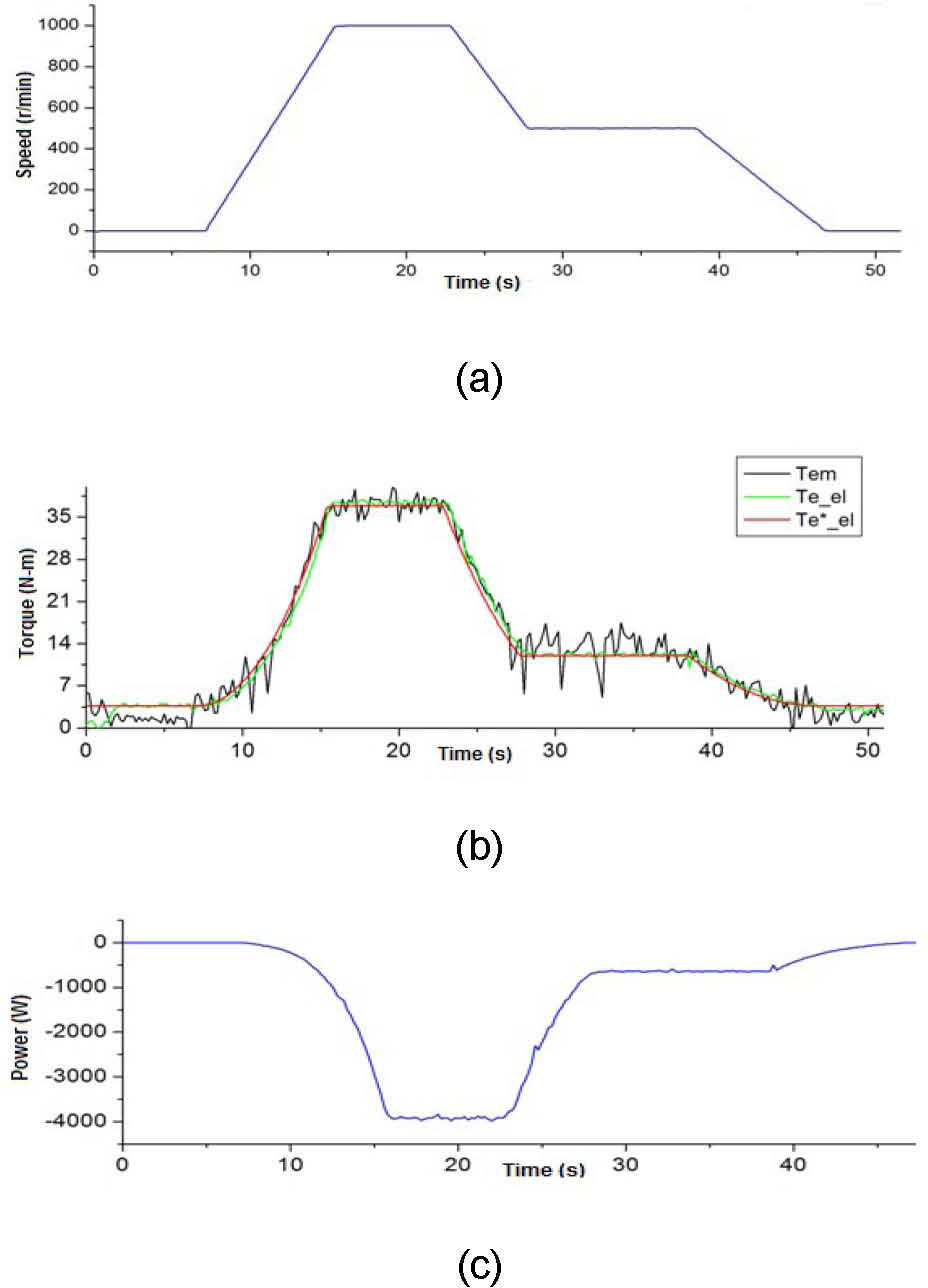

Figure 8 illustrates the simulation results. Figure 8a shows the reference speed profile (block ωm in figure 7) and figure 8b shows the electromagnetic torque of the drive machine Tem (Te in the block PMSM Model of fig. 7), the reference torque of the ED Te_el* (block “Torque” in figure 7), and the torque produced by the load machine Te_el (Te in the block PMSM Model 1 in figure 7).

In figure 8c negative power in the shaft means power regenerated by the ED and sent to the grid. For this particular load profile (fan), the load machine works always as a generator being the power flow unidirectional.

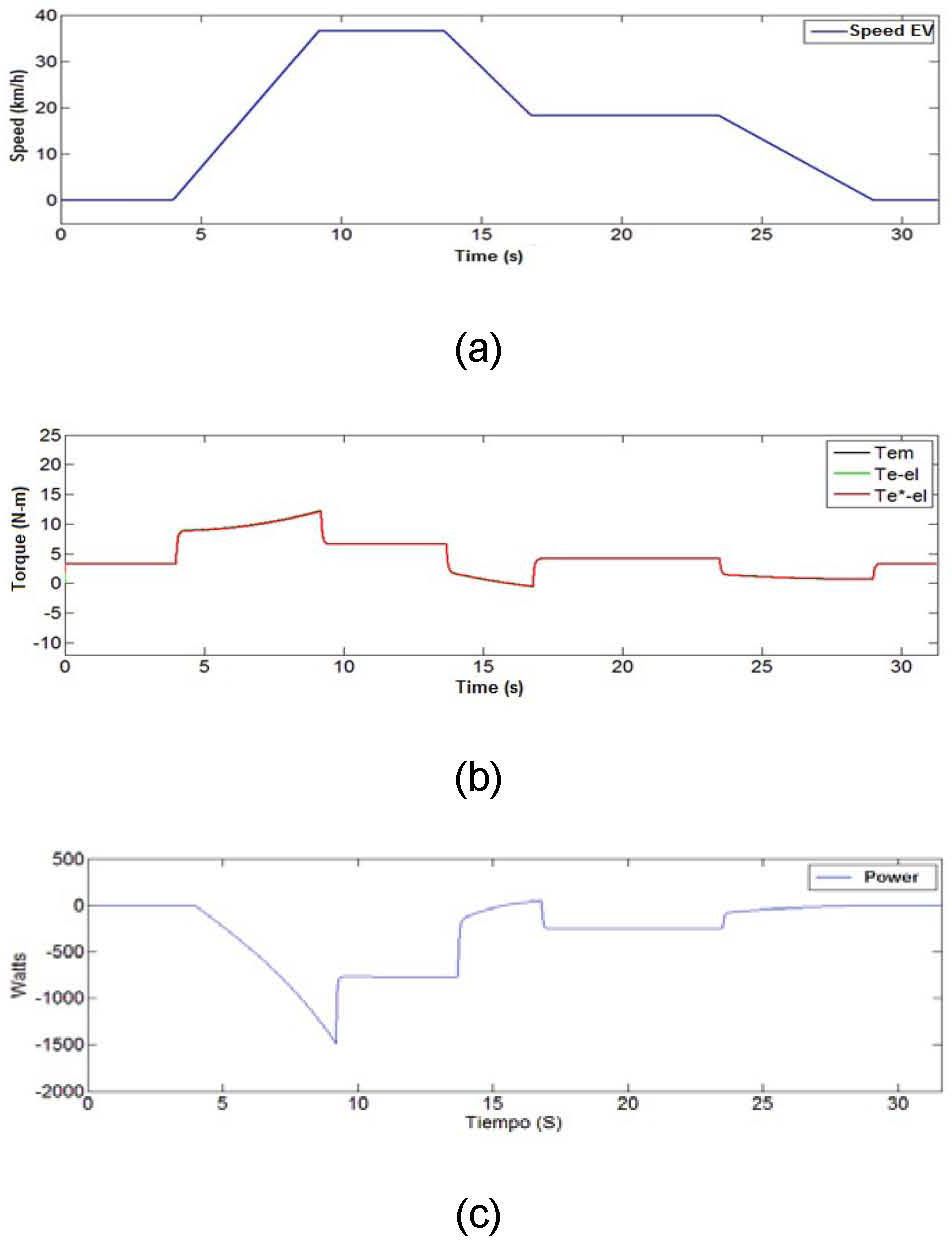

Figure 9 illustrates the simulink simulation results for the second test in which an EV load profile is used.

The EV speed profile used is shown in Fig. 9a. The reference speed ωm* is the input to the loop control of the traction machine as shown in Figure 4, it was calculated from equation 7.

The traction torque values for the EV were calculated from equation 6. The iqs* value for the load machine was calculated by applying equation 5. Variations of the traction machine torque are illustrated in figure 9b. Figure 9c illustrates the power in the shaft of the traction machine, negative values corresponds to power regenerated by the electrodynamometer and sent to the grid (electric traction), the positive values are due to the regenerative braking of the traction machine. The increase of the voltage in the DC bus of the inverter (see Figure. 9d) is due to the regenerative braking of the EV. Figure. 9a shows a sudden change of the reference speed from 37 km/h to 17 km/h during the period of time from 13 to 17s, resulting in kinetic energy converted to electric energy by the traction machine, that energy is sent to the DC bus through the power inverter resulting in an increase of the DC bus voltage. The reference speed is set by means of the vector control of the traction machine (see figure 4).

4Electrodynamometer Hardware implementationFigure1 illustrates a block diagram of the experimental setup and figure 2 shows a picture of the system as it was implemented in the laboratory. Figure 10 shows the power converters (Unidrives SP 3201) connected by means of the DC bus of 300V, these converters can work as rectifiers or inverters depending on the power-flow direction (traction or breaking). The Unidrive driving the load PMSM works on the “servo” mode controlling speed and torque of the load motor. The other Unidrive connected to the grid works in “regen” mode.

In the “servo” mode terminals 5 and 6 of the motor drive [15] are used to control the speed of the ED, these terminals are configured in differential voltage mode. The voltage in those terminals is related directly with the reference speed value. As the speed is determined by the traction machine the reference speed for the load machine was set to 0. In this way the electromagnetic torque developed by the load machine is independent of the speed which is set by the traction machine controller. Terminal 7 of the Unidrive working in “servo” mode is used as the input for the reference torque value for the ED. The reference torque signal to emulate an EV is generated by the PC where the model of the EV was programmed. That signal is fed to terminal 7 of the Unidrive by means of the National Instruments electronic board NI USB 6211. The value and direction of the load-machine torque is related to the magnitude and polarity of the voltage fed to that terminal.

5Experimental resultsFigure 11 illustrates the experimental results for a fan load-profile. Equation 8 was programmed in Labview using the same data as in the simulation and by means of the NI USB 6211 board a reference torque value is set in the Unidrive working in the “servo” mode which forces the load machine of the ED to exert a fan torque (equation 8) on the drive machine.

The speed profile illustrated in figure 11a is the reference speed for the vector control of the traction machine. Figure 11b shows the electromagnetic torque of the traction machine Tem, the reference torque of the ED Te_el*, and the torque produced by the load machine Te_el. The torque Tem fluctuations of the traction machine are due to the fact that this signal is taken from a PWM output of the DSC where the traction machine control was implemented. The signal was filtered and then was acquired by a NI USB 6211 board to be plotted finally by Labview along with the other torques. Figure. 11c shows the power in the shaft of the traction machine being always negative which indicates that the power flows to the load machine which in its turn sends it to the grid.

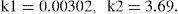

Experimental results illustrated in fig. 11 correlates well with those gotten by simulation and illustrated in figure 8. Figure 12 illustrates the experimental results for an EV load profile which also correlate well with the simulation results (Figure 9), validating the models developed for the motor control and ED. The EV parameters needed (see equation 6) are listed in the appendix B. Figure 12a shows the EV speed-profile which is typical for a driving cycle. Figure 12b shows the electromagnetic torque of the traction machine Tem, the reference torque of the ED Te_el, and the torque produced by the load machine Te_el, all of them correlate well suggesting that the system is working as it was expected. Figure 12c illustrates the shaft power, it can be seen that negative values corresponds to power delivered to the grid by the ED which indicates that the EV is operating in the traction mode meanwhile positive power values correspond to the regenerative braking mode and the traction machine works as a generator.

The energy regenerated by the traction machine is delivered to the DC bus by the DC/AC converter (Powerex PP75T120) this energy is blocked by the diodes connected in series with the power supply (TDK-Lambda GEN 300-17) resulting in an increase in the DC bus voltage as shown in fig. 12d.

6ConclusionsThis work addressed the design, commissioning and testing of an ED based on PMSMs to assess the dynamic performance of an EV. Simulation and experimental results correlated well for load profiles corresponding to a fan and an EV. It was possible to emulate the traction and regenerative braking stages for an EV validating the simulation results. As the load profile is programmed in a PC by means of Labview the system is very flexible and other kind of load profiles can be emulated by modifying the Labview program. The system is aimed to emulate EV load profiles however it can be applied to investigate on areas such as smart grids, renewable energies (wind power) making it a worthwhile investment.

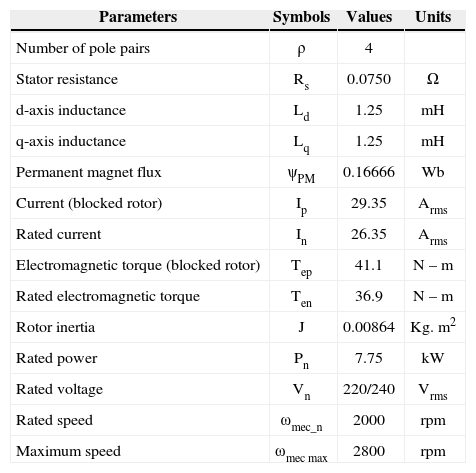

Motor Specifications.

| Parameters | Symbols | Values | Units |

|---|---|---|---|

| Number of pole pairs | ρ | 4 | |

| Stator resistance | Rs | 0.0750 | Ω |

| d-axis inductance | Ld | 1.25 | mH |

| q-axis inductance | Lq | 1.25 | mH |

| Permanent magnet flux | ψPM | 0.16666 | Wb |

| Current (blocked rotor) | Ip | 29.35 | Arms |

| Rated current | In | 26.35 | Arms |

| Electromagnetic torque (blocked rotor) | Tep | 41.1 | N – m |

| Rated electromagnetic torque | Ten | 36.9 | N – m |

| Rotor inertia | J | 0.00864 | Kg. m2 |

| Rated power | Pn | 7.75 | kW |

| Rated voltage | Vn | 220/240 | Vrms |

| Rated speed | ωmec_n | 2000 | rpm |

| Maximum speed | ωmec max | 2800 | rpm |

EV parameters.

| Parameters | Symbols | Values | Units |

|---|---|---|---|

| Gearbox ratio | rt | 8.83 | - |

| Motor inertia | Jm | 0.00057 | kg/m2 |

| Wheel inertia | JW | 0.164 | kg/m2 |

| Wheel radius | rW | 0.274 | m |

| Efficiency of the mechanical transmisson | ef | 1 | - |

| Distribution factor | df | 1 | - |

| Mass of the EV | m | 100 | kg |

| Friction coefficient | Kr | 0.057 | - |

| Road slope | ∝ | 0 | rad |

| Gravitational acceleration | g | 9.8 | m/s2 |

| Aerodynamic drag coefficient | cd | 0.31 | - |

| Air density | ρ | 1.23 | kg/m3 |

| Frontal area of the EV | Af | 1.75 | m2 |

![Experimental results. (a) EV speed km/h, b] Electromagnetic torque N-m; (c) Power in the shaft W; (d) DC bus voltage in the traction-machine inverter V. Experimental results. (a) EV speed km/h, b] Electromagnetic torque N-m; (c) Power in the shaft W; (d) DC bus voltage in the traction-machine inverter V.](https://static.elsevier.es/multimedia/16656423/0000001200000003/v2_201505081651/S1665642314716189/v2_201505081651/en/main.assets/thumbnail/gr14.jpeg?xkr=ue/ImdikoIMrsJoerZ+w96p5LBcBpyJTqfwgorxm+Ow=)